The simplest do-it-yourself sewage system in the country will significantly improve the living conditions of the owners with a minimum investment. The apparent simplicity of the problem hides technological nuances that will help a novice plumber to qualitatively equip suburban life.

- Types and arrangement of sewerage for a summer residence

- Natural wastewater treatment with a septic tank

- Biochemical cleaning

- Actual requirements for the placement of the sewage system on the site

- Choice of materials

- Designing and carrying out the necessary calculations

- Required tools

- Preparatory work

- Installation steps

Types and arrangement of sewerage for a summer residence

Classification of the main types of devices in rural areas:

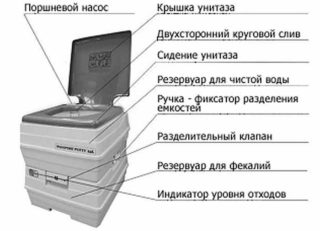

- dry closet;

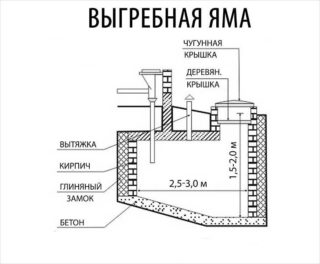

- cesspool with a dug-in barrel;

- storage device;

- septic tank;

- biological station.

Having installed a dry closet, the owner is faced with the problem of drainage from other plumbing fixtures: showers, sinks and washbasins. A characteristic unpleasant odor is always present in such devices.

- possible overflow with the need to pump out;

- sewer smell;

- pollution of the territory.

If there is no water supply system at the dacha, the volume of the pit will be enough for a long time. Restrictions on the use of cesspools are introduced for areas with high groundwater levels and clayey soils.

The storage tank is one of the modern options for cesspools. Their advantages are in tightness, due to which the garden area is not polluted, and the possibility of installing containers of different volumes. The sewage storage tank can be installed both on the surface of the earth and underground. A storm sewer can be connected to the tank. Cons: the need for frequent pumping out of sewage and the presence of odor.

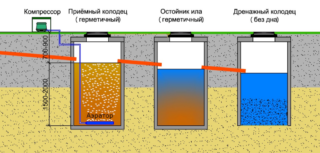

Natural wastewater treatment with a septic tank

The device consists of several compartments. With an increase in their number, the quality of the treated water rises. The septic tank cleaning method has several advantages:

- simplicity of design;

- low cost;

- does not require electricity consumption;

- does not pollute the soil;

- there is no unpleasant smell;

- there are ready-made designs.

Once a year, according to the results of an external examination, it is recommended to clean the drainage system and septic tank compartments.

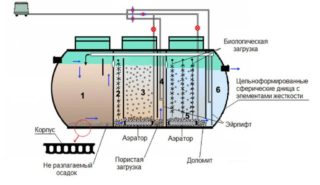

Biochemical cleaning

Biological treatment complexes are expensive, but they can disinfect wastewater up to 98%. Device advantage:

- long service life up to 50 years;

- minimal maintenance.

The choice of a local biological treatment device is influenced by the number of people living in the house. It is recommended to choose the power with a small margin, since the duration of operation implies a constant change in the number of people. To determine the level of the tie-in to the station, it is necessary to know the height of the collector leaving the house. The tie-in level is designed for 60 cm, 90 cm and 120 cm. The discharge point influences the choice of a forced or gravity drainage system.

Actual requirements for the placement of the sewage system on the site

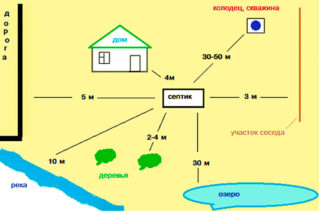

A distance of 5 m to the foundation of the house will not allow the base of the building to be washed out by the water leaving the sump. Increasing the distance to 15 m requires the installation of an inspection well, which, according to the operating rules, is installed every 10 m.

The distance to the source with drinking water should be at least 50 m, to the lake or pond - 30 m, to the river - 10 m.The distance to the border of the site is determined - 4 m, to the road surface - 5 m.

It is necessary to provide the possibility of passage of sewage equipment to the septic tank for emergency or periodic pumping out of the contents.

Choice of materials

The sewerage system is divided into internal and external. Each of them has certain requirements regarding the material for the manufacture of sewer pipes, since the conditions of their operation differ.

External sewage pipes are laid underground according to the project, the angle of inclination provided by SNiP for pipes of different diameters is observed. The main requirements for their quality are determined by the following factors:

- long-term operation;

- resistance to pressure from drains and soil;

- corrosion resistance;

- resistance to aggressive substances;

- smoothness of the inner surface of the pipes to maintain their throughput.

Manufacturers offer several materials for sewer pipes: cast iron, polypropylene and asbestos cement. The most durable cast iron pipes, but the roughness of the inner surface reduces the throughput, contributing to silting. In addition, they are expensive and installation requires connecting fittings and embossing.

Pipes made of polypropylene and polyethylene - withstand temperatures up to 40 degrees, for a short time - up to 60. Their cost is lower, the inner surface is smooth. The plastic pipe system can be easily connected using fittings of various configurations. With a diameter of more than 200 mm, pipes with an outer corrugated surface are produced.

For internal wiring, they buy gray polyvinyl chloride pipes, for external sewerage - red ones made of polypropylene.

Designing and carrying out the necessary calculations

To make a country sewage system without pumping out with your own hands, instead of a cesspool, a septic tank is installed from concrete goods, which allows you to much speed up the process of wastewater treatment. Advantages of reinforced concrete rings over monolithic structures or plastic containers:

- The monolith requires work with reinforcement, mortar and formwork. Reinforced concrete rings can be laid in a matter of hours.

- Durability of concrete products.

- Plastic tanks in the form of barrels or eurocubes must be fixed to the concrete base to avoid the effect of pressure from below, which could push the light tank out of the pit.

In the budget version, a homemade container from tires is used. Tires from a tractor will do.

When calculating the volume of the container, they proceed from the number of people living in the house, and the daily rate of water consumption - 200 l / day. The standard provides for the volume of effluents in three days.

For example, for 5 people, you will need a capacity of 3 cubic meters (5 * 200 * 3 = 3000 liters).

The number of cameras also depends on the number of residents. For a family of 3 people, one camera is enough, in this case, a sewage system in the country from a metal or plastic barrel is the most economical option.

For 4-6 people, a two-chamber septic tank is required. In one part, anaerobic decomposition of the settled sediment takes place without access to air, the clarified water is discharged into the second tank, where it is additionally purified with the help of aerobic bacteria. Then the purified water is poured into a resorption well, which has holes in the walls to conduct water into the ground. The bottom of the well is lined with gravel for additional filtration. If the soil water level is high or the soil is loamy, a trench is made instead of a well to increase the filtration field.

Calculate the number of rings required for the construction of septic tank compartments using the size of the inner diameter: V = πd2h / 4, where h is the height of the ring. The calculated volume of the container is divided by the volume of the ring, with an odd result, add 1.

Required tools

When digging a hole for a septic tank, you will need a trenching tool: bayonet and shovels, a pickaxe and a crowbar. For hard ground, an excavator is hired.

When installing the domestic sewage system, you will need a perforator to make holes in the partitions, a level for the correct laying of pipes with the desired slope. For sealing knocked-out holes: trowel and mortar container.

Preparatory work

Having made the measurements, they begin to design a sewage system from concrete rings in the country. It is necessary to dig a pit during the period of lowering the groundwater level. Usually this is the hottest summer time or the first frost.

The pit should have two tiers. The second compartment is installed half a meter lower than the first. Manually or with the help of an excavator, trenches are dug for laying sewer pipes at a depth below the level of soil freezing so that the system does not freeze in winter. The bottom of the trenches is made with a slope of 2 cm by 1 m, sand is poured on top with a thickness of 20 cm.

Installation steps

When digging a pit, 30 cm from all sides are laid on the installation gap between the containers. The distance between the rings of adjacent compartments is 5-10 cm. When determining the depth of the pit, the height of the backfill is taken into account. Experts advise to make the distance between the wells by 50 cm and fill the gap with rubble. It will act as a buffer cushion during ground movement.

If reinforced concrete rings are without a bottom, a concrete slab with a thickness of at least 10 cm is poured, reinforcing it with a mesh. Like all reinforced concrete structures, rings with a bottom require a 20 cm sand cushion when laying. To install the rings, use a cement mortar, evenly applying it to the contact surface.

In the chambers, holes are marked and punched in the upper part for the passage of pipes. The inside of the ring is coated with a hydrophobic impregnation. From above, the finished compartments are covered with concrete roofs with inspection hatches. The pipes are laid at a slope of 2 cm by 1 m towards the septic tank for a gravity drainage device.