The sewerage layout in the apartment has its own characteristics. Homeowners in new buildings are often faced with the problem of installing plumbing. Sometimes the outlet point to the riser is too high from the floor, so you have to raise the shower stalls to ensure the desired slope. The reliability of the drainage system depends on compliance with SNiP during installation and selection of materials.

How is the sewage system in an apartment building

Removal of sewage contaminated with household waste is arranged according to the principle of gravity, therefore it is important to observe the angles of inclination of the pipes provided for connecting each plumbing fixture. The sewer riser has an outlet to the atmosphere on the one hand, and an outlet to the inspection well on the other. Sinks, bathtubs, showers are connected to the sewerage system through siphons, which prevent the penetration of gases into living quarters. Toilet bowls and bidets have built-in water traps.

Volley drains, when using toilets, create a vacuum, which is balanced by atmospheric air entering the riser through the outlet on the roof. Without this device, the low pressure zone would facilitate the suction of water from the siphons, clearing the way for the accumulated gases to escape.

Required pipeline slope

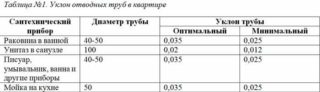

SNiP rules provide for the following slope rates per linear meter for pipes of different sizes:

- D200 mm - 7 mm / m;

- D160 mm - 8 mm / m;

- D110 mm - 20 mm / m;

- D50 mm - 30 mm / m.

It is not recommended to conduct the wiring horizontally, as this will lead to a stop of the self-cleaning function, which will not allow waste to flow towards the sewer well. Possible consequences: flooding of the basement, silting up of the pipeline, disruption of the siphon system.

Planning and carrying out the necessary calculations

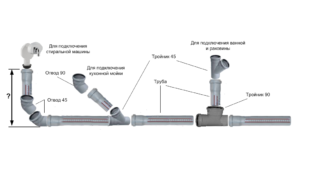

The sewerage diagram must indicate:

- premises of bathrooms and kitchens;

- location of risers;

- distance to walls when connecting plumbing;

- fittings and revisions;

- taps for cleaning.

The length of the sections, the diameter of the pipes and the angle of inclination are indicated. After that, calculations are performed, which include:

- number of pipes of different diameters;

- connecting and transition couplings;

- adapters from plastic to cast iron;

- sealant;

- additional fittings for turns and branches;

- other consumables: rubber cuffs, pads, crutches, etc.

You should use as little scrap as possible, since each connection will require the presence of couplings, which reduces reliability, aesthetics and leads to an increase in the cost of work.

The diameters are chosen depending on the installation location: for the riser, d 110 mm, d160 mm and d200 mm are used.The wiring around the apartment is made of pipes d40 mm and d50 mm. To connect to the drainage system of dishwashers and washing machines use d32 mm.

Choice of materials

Polymer products have obvious advantages over cast iron casting: lighter weight, a wide variety of fittings for any configuration, corrosion resistance and long service life when operating in the selected temperature range.

Polyethylene

The material is cheap, but it deforms easily when exposed to high temperatures, since it has low heat resistance. The pipeline assembled from it allows leaks. Products made of polyethylene are not recommended for the installation of the sewerage system due to the poor technical quality of the material.

Polypropylene

It has high strength, so it allows you to remove blockages using plumbing cables. Resistant to high temperatures (up to 130 degrees) and to solutions of chemically active substances. Products have a high hydraulic resistance due to the rough inner surface, therefore it is recommended in pipelines with a large diameter.

Polyvinyl chloride

The best choice for do-it-yourself sewer installation. Its advantages are low cost, strength and durability. The temperature of the drains is allowed up to 80 degrees. Compared to polypropylene, it has better hydrodynamic characteristics, but has lower chemical resistance.

Dismantling the old system

To disassemble the sewer riser, they choose the daytime, when most of the neighbors are at work. It is recommended to wear a helmet. It is important to complete the preliminary activities:

- turn off the hot and cold water supply in the basement;

- cover the floor and walls with a protective film; tape can be used to connect the joints;

- prepare a raincoat and rubber boots in case of an emergency.

Dismantling the plastic system is not difficult; it consists in unscrewing the old pipes.

The alteration of the cast-iron wiring will require a lot of effort, since the joints are joined by a caulking method using asbestos or linen cords and cement mortar. If necessary, act with the help of a grinder: cut a hole; insert a wedge and, hitting it, break the cast-iron product into pieces.

First, disconnect the pipe from the riser using 2 cuts. The remaining branch into the riser is hammered with a hammer to remove the remnants of the fragments. The hole is plugged with rags. Then they begin dismantling from the end of the wiring, from the plumbing fixtures. At the last stage, the riser is cut off and work begins to replace it.

Stages of installation of the sewer system

They collect the sewer according to the scheme, sealing the joints of the elements, then connect the plumbing. At the last stage, the outlet is mounted into the sewer riser. Check for leaks after a certain time required for the sealant to solidify. It is applied to the inner part of the connecting pipe and the outer section of the pipe inserted into it.

Common mistakes

Failure to comply with the rules for installing sewage in an apartment leads to emergency situations.

- A large number of horizontal branches, made at right angles without observing the angle of inclination. It is advised to rotate at an angle not less than 130 degrees. This avoids the occurrence of debris congestion and extends the life of the sewer.

- Failure to comply with the slope. If the semi-basement low room does not allow correct installation, evacuation pumps are installed to ensure the forced discharge of sewage. In this case, waste shredders are needed, which increase the cost of setting up the system.

- Pooling drains from sinks and toilets causes grease to settle on the surface of the pipes, which contributes to the rapid formation of blockages.

- Incorrect calculation of the performance of the sewer system. Sewerage of an apartment equipped as an office with a large number of employees may not be designed to increase the volume of drains, which leads to flooding of the floors below.

- When sealing joints, you need to focus on reliability, not aesthetics.

In private houses, an emergency can be caused by a shallow laying of the pipeline, which does not take into account the depth of freezing of the soil.