A red sewer pipe with a diameter of 250 mm is the most commonly used product when installing external sewage systems. Since the street highway is subject to static and dynamic loads, special requirements are imposed on the selection and installation of its components. Product specifications vary with length and service requirements.

Scope of application of plastic sewer pipes with a diameter of 250 mm

In the marking of pipes, the outer size is indicated, therefore, the inner diameter has to be calculated independently, subtracting the wall thickness from the available indicator. For external drainage networks, the diameter is not regulated, however, there are recommendations according to which the size of the pipe at the outlet should not be less than the external line.

For suburban areas, pipes from 110 to 250 mm are chosen. In systems with a higher load, the diameter can be increased up to 400 mm. The wall thickness varies depending on the length of the cut pieces.

Scope of products with a diameter of 250 mm:

- Sewer pipes and fittings are often used for internal wiring in drainage systems.

- Drainage of melt water and household waste from residential and industrial facilities.

When choosing pipes for production facilities, you should pay attention to the acidity level in the system - the pH should be from 2 to 12.

Specifications

PVC sewer pipes are made from high quality raw materials. They are designed to transport wastewater in an external sewage system with temperatures up to 60 degrees. For a short time (up to 2 minutes), water supply up to 100 degrees is allowed.

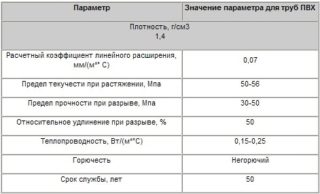

Technical characteristics of PVC pipes with a size of 250 mm have the following characteristics:

- The density of the material is 1410 kg / m3.

- Heat capacity - 1.0 J / g.

- Modulus of elasticity at deformation of 1 mm / min - 3000 MPa.

- Thermal conductivity at a temperature of 23 degrees - 0.15 W / m.

- The maximum bending radius of the pipe is 300 mm at a temperature of 20 degrees.

- Installation in a temperature range from -5 to +90 degrees.

The advantages of PVC pipes for outdoor sewerage include high strength, low weight, resistance to internal wear and wall overgrowth, and corrosion resistance. Since plastic products are more durable when used in a humid environment, their installation in the sewer system turns out to be more profitable than the installation of metal elements.

The service life of plastic pipes with a diameter of 250 mm is 30-40 years, although manufacturers give a guarantee for 10 years of service. A long period of operation is observed subject to compliance with standards that do not allow unnaturally intense loads.

When calculating systems based on fluid circulation, it becomes necessary to determine the throughput of pipes. This value characterizes the volume of liquid that is transported through the pipes over a certain period of time. This indicator is directly related to the material from which the sewage system is made. Plastic products have the same throughput throughout the entire period of operation. The plastic is not subject to corrosion, so the inner surface remains smooth until the damaged areas are dismantled.

When calculating the throughput of the pipeline, the length of the section from the internal sewage system to the point of insertion into the central highway or septic tank is important. The greater the distance the liquid travels, the less pressure is created in the pipes, which means that the flow rate decreases. For pipes with a diameter of 250 mm, laid with a slope of 0.008 and a flow rate of 1.09 m / s, the water flow delivers 33.6 l / s.

Installation features

Pipes with a diameter of 250 mm are often used for external sewage, therefore, when installing them, it is necessary to take into account the features of the device of external networks. Stages of work:

- Creation of a network diagram. The compiled documentation indicates the features of a particular site. The location of the pipes is marked in the plan. The circuit should be preserved even 10 years after operation.

- Pit marking. It is performed using twine and pegs. It is best to use this method as the marks on the ground are easily erased. If you make mistakes in the marking, system malfunctions may appear during operation.

- After marking the ground, they begin to dig a pit.

- The bottom layer of the pit is covered with pebbles, which prevents the soil from being pushed through to protect the pipes from groundwater. In addition, this measure improves the thermal insulation of the sewage system.

Since plastic pipes freeze easily, they are wrapped in a metallized polyethylene-based material. They also cover the entire bottom of the septic tank pit. The metal surface should face up.

The assembly of an external sewage system using pipes with a diameter of 250 mm consists in immersing all elements of the system into a pit and trenches suitable for it. Subsequently, individual sections of the network are connected to each other, and the joints are sealed with tape or a special liquid.

For thermal insulation, the pipe is wrapped with glass wool or polyester. This measure prevents the drains from freezing in winter. The line is buried after testing the system. It is possible to check the system for operability only after the sealant has completely dried, which can take from several hours to several days.

- Kleev (cold welding). A compound is applied to the fittings that can connect the elements at the molecular level.

- Bell-shaped. Docking of sections is carried out by deepening straight products into sockets, pre-treated with a sealant.

The key to the wireless functioning of the outdoor sewerage system is strict compliance with the installation technology. When building a highway, certain rules must be followed. A crushed stone-sand pillow is poured into the bottom of the trenches. It protects the pipeline from damage due to seasonal ground movements. The line must be laid at a slope of 2-15%. If it is necessary to change the direction, bends of 15-30 degrees are used. It is worth installing revisions every 15 m of the sewage system. When backfilling the ditch, the soil is tamped only from the sides. The soil under the highway does not require compaction.

The cost of plastic pipes with a diameter of 250 mm

All large diameter pipes are sold in lengths of several meters. Prices for plastic sewer pipes with a diameter of 250 mm depend on the footage, wall thickness, density and material processing characteristics.

Non-pressure plastic pipes with a diameter of 250 mm cost 550 rubles. per running meter, pressure head - 650 r. Their main difference lies in the wall thickness. This indicator greatly increases the cost of production. A corrugated pipe, due to its greater strength, costs from 700 to 750 rubles. for 1 m.

Subject to the rules for laying the sewer main and the conditions of its operation, the service life of the system will be comparable to the lifetime of the house itself. Regular work includes checking the inspection hatches and periodically cleaning the pipes.