A sewer collector is a hydraulic structure that includes a large-diameter main drain line and its branches for draining sewage into a treatment device or storage. The device can be of different types. Each of them can actually be assembled independently, it only takes an investment of money, time and labor.

Purpose and design features

- brick;

- reinforced concrete - monolith or ring products;

- plastic - polyethylene, polypropylene and PVC.

The latter option is in the greatest demand due to the value for money. To give the plastic pipeline the necessary rigidity, the walls are corrugated. And so that the uneven surface does not reduce the throughput, the inner layer is made smooth.

Collector networks and sedimentation tanks of individual houses or even microdistricts are united by common wells: they are necessary for the inspection of devices and networks, their preventive or emergency cleaning. The installation of well structures is also required at key points and at bends.

Rotary structures in sewers are usually equipped with gutter inserts with a guiding function. They are necessary to reduce the hydraulic resistance of the water flow - so it can easily overcome even difficult curved sections.

There are special drop wells - they are used on complex landscapes, if it is necessary to modify the depth of the sewerage pipelines.

Underground sewers require high-quality ventilation. For this, the system is equipped with free-standing pipe sections (with a cross section of at least 300 mm). They are installed at a distance of no more than 0.5 km from each other.

How it works and benefits

According to the principle of operation, collectors are classified as follows:

- Collecting waste water from only one sewer basin.

- Main devices collecting drain fluid from two or more collectors;

- Suburban structures that drain wastewater to treatment facilities, pumping stations or into a reservoir.

The installation of the collector complex must be done correctly, only this guarantees a reliable drainage of drains. Installed in both gravity and pressure systems.

The pressure sewer manifold is equipped with a pump. Such a system is easy to build on any terrain. All waste goes into a special sealed tank, then, with the help of a pumping station, it is crushed and pumped to the treatment plant.

The main advantages of the pressure-type collector network are:

- Reducing the volume of installation work.

- Savings on materials due to the fact that the length of the pipeline is less than with a gravity system.

- Reduced installation time.

A properly assembled manifold system can last more than half a century without replacing parts.

The cross-section of pipelines for the collector network depends on the volume of wastewater, and their throughput is calculated so that the flow rate is no more than 0.7 meters per second. When it is reached, the sewer pipelines are capable of self-cleaning.

Types of reservoirs for the collector

The reservoirs connected to the mains are used to accumulate polluted waters or to clarify and filter them. In domestic conditions, three types of collector pipelines are used, and treatment tanks are selected in accordance with the purpose.

Household collector

The choice of a household cleaning device depends on several factors:

- mode of use;

- the number of residents;

- dependence on energy resources;

- soil features.

There are small treatment facilities for summer cottages and small-family houses, as well as complexes that can serve an entire village. When choosing, the ability to connect to a power source is taken into account.

If a non-volatile system is more convenient, cesspools and septic tanks are installed - hermetic or drained. They do not need to be connected to electricity, it is quite simple to mount such devices. But the cesspools need to be cleaned regularly.

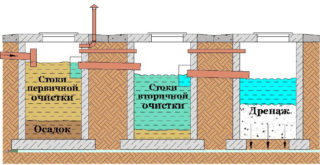

Septic tanks do not need frequent pumping, but biological products must be constantly added. The essence of such structures is in the processing of organic waste by special microorganisms. The liquid is clarified up to 75 percent. For greater purification and safe discharge into a reservoir or soil, it is necessary to install special biofilters.

A variety of septic tanks are aerotanks. They use aerobic bacteria, the vital activity of which is supported by the forced supply of oxygen to create a layer of activated sludge. A larger amount of sewage is processed in it.

In large houses where people live permanently, it is reasonable to install a deep bio-purification station. Due to the complex of various cleaning devices, the drain liquid is clarified by 98 percent. The disadvantages of such equipment are high cost and energy dependence. They also require forced aeration, but practically do not need to be cleaned.

Manifold for storm water

- washing cars and asphalt surfaces;

- watering a flower garden, horticultural crops;

- summer shower.

The pipes themselves are laid shallow below the surface of the earth. The reservoir is buried below the freezing point and insulated. Wells are equipped with pumping equipment: submersible, semi-submersible or surface.

Drain collector

Perforated drainage pipes are laid deeper than stormwater lines. This is necessary to collect excess moisture from the inner layer of the earth. Plastic tanks are also used as sedimentation tanks or reinforced concrete wells are created.

Water from the drainage reservoir is also allowed to be used for technical needs.

If lightweight polymer structures are used, they must be anchored with anchors to the concrete screed at the bottom of the well. Otherwise, the container will float up during a flood, or its walls will be deformed.

Collector network installation

After carrying out measurements and drawing up a project of the structure, earthworks are carried out:

- Below the freezing level of the earth, a ditch is dug under the collector lines and pits for wells.

- A sand and gravel cushion about 15 cm thick is laid at the bottom of the trenches, rammed. Pipes are laid on top or well tanks are installed.

- For a gravity sewer system, the mains are mounted with a slope of 2 cm per meter of pipe towards the storage tank.

- Pipes and plastic containers are insulated, the latter are anchored if necessary.

- The joints are sealed, then the system is tested for leaks by pumping water inside.

If the test is successful, the trench is buried, the outlet of the main line is preliminarily lowered into the drive or connected to a septic tank.

The sewer network is an important part of the sewerage system.If it is installed incorrectly, the entire sewer system will not be able to function.