The downspout elbow is a piece bent at the desired angle. The bypass is used in almost all gutters in order to successfully combine a drainage system and a funnel that collects sediments, bypass architectural obstacles and protect the foundation.

Purpose of the product

The elbow looks like a short pipe bent at an angle of 45, 60 or 90 degrees. The element has several important functions:

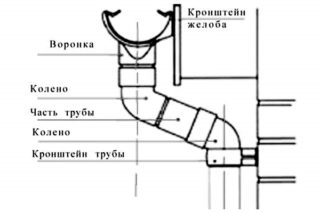

- The vertical part of the drainage system is fixed as close to the wall as possible - at a distance of 3-5 cm. But the funnel for collecting water lags behind the vertical by a greater distance. You can only connect them with a pair of knees.

- Buildings are equipped with cornices, bay windows, columns and other architectural elements. The assembly of straight drain lines is not possible. In the most difficult cases, up to six knees are used.

- The knee piece helps to organize the drain. If liquid flows directly from the gutter, it spills directly onto the blind area and can damage the wall and foundation base. To increase the distance, a bypass of the required length is placed on the lower part of the drain pipe.

Sometimes marks are used for decorative purposes to create a proportional composition. They are made in a contrasting color compared to the main system.

Element types

Parts are subdivided according to configuration and material. For the manufacture of bypass elements are mainly used:

- steel alloys that are pre-galvanized;

- stainless steel;

- polymeric materials, most often PVC.

The last option is distinguished by budget cost and moisture resistance. However, polyvinyl chloride cannot boast of increased strength and can burst with rough installation or direct impact.

Galvanized steel marks are more durable. They are also lightweight and easy to install, but they make a lot of noise during bad weather and can rust over time if the galvanized layer is damaged.

Stainless steel options are the most durable. But such systems are quite expensive.

There are combined options for drainage systems. For example, if the main body of the gutter is made of galvanized steel and coated with polymer. They also combine metal and PVC parts in one system. For example, a galvanized funnel can be connected with an elbow to a plastic drain pipe.

Bypass parts can be corrugated. This gives the product flexibility - it can be adapted to any architectural features of the building. For rigid models, the angle is always the same. They are more durable and less clogging.

The quality requirements for any kind of knee are very high. Connecting parts are most vulnerable due to the presence of abutment seams. In these places, the system begins to collapse.

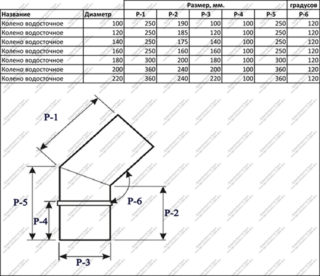

Product dimensions

The mark usually does not exceed 35 cm on each side. If the distance between the eaves and the wall is greater, the suitable bend bypasses are attached using an additional pipe cut. This is how the elements are matched even in the most inconvenient places.

The smaller the angle of the sweep, the more freely the water passes through the drain. Debris tends to accumulate on steep bends. Therefore, they try to use rectangular products as rarely as possible.

The size of the required segment is equal to the distance between the cornice and the wall at the desired angle, taking into account the dimensions of the gutter and drainage system.

The cross-section of a galvanized or polymer elbow of the drain pipe is standard - from 10 cm and more. If the system is made to order, then the connecting parts are also adjusted to the required dimensions.This also applies to the size of plastic and metal gutter elbows.

Installation features

Installation of products made of polymers and metal differs at the stage of connection to the water intake. The plastic bypass of the pipe is mounted with a rubber seal. It is necessary to create a sealed pipeline. The O-ring is fixed with special glue.

The steel bend is put on the inlet funnel and secured with a special clamp. The method of joining with the drainage section depends on the type of the latter.

Further assembly is identical for products from any material. The drain, located in the vertical plane, is connected to the second elbow and secured with clamps. After the installation of the system is carried out using sleeve connectors.

The cost of the part is low. It ranges from 100 to 500 rubles, depending on the material. It is more profitable to purchase them from manufacturers or in the complete set of the entire drain.

When choosing metal products, focus on the reliability of the seam fastening of the joint, which is primarily subjected to loads in the entire drainage system and often breaks it. Most often this happens in winter and spring, when there is a lot of precipitation, ice and snow on the roof melt, but outside temperatures remain below freezing.