The sewer expansion joint is designed to repair the pipeline without disassembling the entire pipeline. This device belongs to adapters and is used for various needs - from compensating for linear temperature changes to joining pipe sections with different diameters.

Purpose and technical characteristics

The fitting also has another purpose. It gives the desired slope to horizontal sections when unifying waste branches from different materials.

Fitting is often required in bathrooms or baths, when the floor level changes during renovation work. As a result, it is required to lower or raise the crosspiece on the riser in order to create the correct drainage angle. Also, fittings are used to connect pipes with different sections.

The device allows you to replace a damaged area without completely dismantling the communications system. It will help if you need to "cut" into the existing sewer network, or replace a fragment of it. The fitting reduces noise, vibration, water hammer and the risk of electrolytic corrosion.

Compensating devices can be of different shapes - rectangular or curved. The standard product has the following technical characteristics:

- length - 280 mm;

- diameter (outside / inside) - 115/110 mm;

- wall thickness - 3.2 mm;

- the maximum temperature regime with prolonged exposure is 95 degrees Celsius.

These characteristics can vary depending on the purpose of the fitting. The warranty period for products is usually two years, but manufacturers declare that the fitting element can serve for half a century.

It is not recommended to use the device under pressure. It is installed only on internal sewage lines or on "hot" water pipes. The need to install or the absence of a compensating sleeve on the sewer risers is indicated in the engineering design of the building.

Types of expansion joints and materials of manufacture

Structurally, the device is a branch pipe at one end of which there is a bell with an O-ring made of rubber. The other end assumes a sleeve connection.

Sometimes devices are equipped with flanges or threads. In the first case, the expansion joints are suitable for mains with a cross section of 63 to 110 mm, in the second - less than 63 mm. To connect the elements of the sewer network from various materials, threaded expansion joints are selected complete with a polymer sleeve.

Modern sewer systems are most often made of polymers. Compensation fittings are:

- polypropylene;

- polyethylene;

- polyvinyl chloride.

Products made of polyethylene and polypropylene are in demand. They make it possible to solve most of the engineering problems associated with the installation and use of sewer networks. However, PVC devices are corrugated, which increases their compensatory qualities.

There are flexible products and models of curved configuration, their field of application is the installation or repair of turning sections of the sewage system.

Polymer expansion joints are corrosion resistant and easy to install. However, the plastic device is absolutely unsuitable for cast iron piping. They also use cast iron products. Although they weigh more, they are much stronger than polymer.

For systems that conduct chemically active effluents, devices made of special rubber are used. To give them even greater stability, they are coated with Teflon spraying. The main method of connection to the pipeline is a flange connection.

When choosing a compensation pipe, you need to take into account the thickness of the walls of the main pipes, their cross-section, and before installation, calculate the length of the pipeline in order to calculate the pressure value at the joints.

Sidebar features

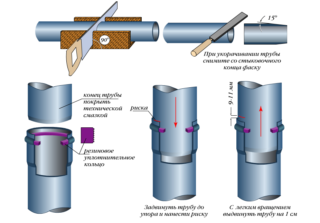

A tapping of a fitting made of polymers is also available to a layman, if you proceed consistently:

- The part of the pipe is cut to which the sewer pipe will be connected. The cut is processed with a file or coarse sandpaper from burrs.

- The top of the pipe is covered with silicone.

- The compensator is put on until it stops.

- The lower part of the riser is covered with sealant.

- A device with a factory is fixed in the pipe socket, where the presence of a rubber seal is checked.

- The system is connected and the riser is fixed.

Reliable fastening of the branch pipe is performed by rigid fixation to the wall with a detachable clamp on a hairpin. The fasteners are placed on the pipe above the compensating device close to it.

Soldering connection

To increase the strength of the connection of polymer pipe sections with thick walls, a welded stubbing technique is used.

For a high-quality connection, you will need a welding machine for soldering polypropylene. The process is as follows:

- The end of the compensating device, entering the plastic pipe, is carefully cleaned from burrs and irregularities.

- The soldering machine is connected to the mains and heated to a temperature of about 260 degrees. When the device is ready to weld, its indicator will go out.

- The prepared end of the pipe and the butt of the compensator are put on the nozzles of the welding machine that are suitable in cross section. When they soften, they are connected.

The plastic parts are bonded so tightly that their molecules penetrate each other's layers. This is called the diffusion method. During solidification, both parts must be rigidly fixed. Do not rotate or move them, otherwise the seam will lose its tightness.

Nuances of installation work

To install the expansion joint correctly on the sewer pipe, you should take into account certain installation nuances:

- the pipes are cut with a fine-toothed hacksaw for metal, so there will be less burrs on the cuts;

- grinding and sealing is carried out only after cleaning and drying the parts;

- all formed cavities are closed with silicone sealant.

The silicone composition for sealing has increased elasticity and will not interfere with compensatory movements, and will also preserve the integrity of the structure during temperature extremes.

The compensator allows you to repair the sewer system without complete dismantling. Installation of polymer models is not difficult. Even plumbing experience is not required to install the device.