In the process of installing the sewer system, it is important to properly fix the pipeline. This will increase its life and reduce the possibility of damage and breakouts.

The main methods of fastening sewer pipes

For fixing metal-plastic pipes, you can use special brackets. They are equipped with clasps that prevent the displacement of vertically located pipe sections, for example, funnels.

This mounting option, such as hanger hooks, is only suitable for attaching sewer pipes to the ceiling.

Most often, the fastening of sewer pipes to a wall or other supporting surface is carried out using special elements - clamps. They come in the following varieties:

- Crimp. The principle of operation is to fix and crimp joints and fittings. Allows to ensure the tightness of the system.

- Guides. They are used for drainage lines mounted on supporting surfaces using markers and fasteners.

- Supporting. Contribute to fixing the pipeline to the wall. Equipped with rubber vibration compensators, which additionally protect against damage.

- Safety. They are used if the installation of additional fasteners is required in a difficult area.

Plumbing clamps are classified according to one more principle - the material used for their production. Metal products contribute to the implementation of extremely rigid and powerful fixation. Plastic models made of polypropylene or PVC allow you to create not only a "dead" fastening of a pipe segment, but also to make a movable connection. They are practical and inexpensive.

Recommendations for choosing a fastening method

The mounting pattern on the supporting surface can be floating or rigid. In the first version, the fastening is carried out by means of guides and support clamps that fix the cross-section of the tie. In the second, it is performed using a crimp and support element, they are put on the shaped part and the bell section. Serve for joining pipe sections and fitting parts. The second option of fasteners is made in order to preserve the integrity of the pipes during thermal deformations.

For rigid fasteners, a clamp is selected that matches the section of the pipe. In places where it is only required to maintain the axial direction of the pipeline, products with a large diameter are used, which compensate, if required, for the thermal expansion of the plastic line.

It is necessary to select options for fasteners taking into account the design features of the room. Plastic clamps are suitable for places with open sewerage. If the funnel is hidden, the main criteria for the selection of fasteners for fixing are its immobility or mobility, deafness or freedom when stretched.

Installation rules for sewer fasteners

To fix the highway efficiently, take into account certain nuances:

- The location of the mounts. Fasteners are installed where the sewer main bends, forks, as well as in the places where reinforcement elements and connecting nodes are installed. In order to correctly calculate the location of the clamps, a preliminary drawing up of a general scheme for laying the sewer line with all the branches will be required. The drawing can be transferred directly to the walls of the room.

- The slope of the pipes. According to building codes, it is at least two centimeters per linear meter of the line. In this case, it is necessary to avoid, if possible, turns at an angle of 90 degrees, which are the most risky areas in terms of clogging the sewer system.

- Alternating non-slip and floating fasteners. Each pipe section must be secured with at least one rigid fixed clamp. It is located at the base of the pipe, where it connects to the rest of the sewage system. In this case, floating clamps should also be installed - on both sides of the fixed one.

- Distance between fasteners. When installing sewer lines made of plastic or metal-plastic, their fastening is carried out with a distance of two meters between the clamping elements. If it is planned to install a heavy pipeline made of steel or cast iron, the clamps are exposed more often, in steps of a meter and a half.

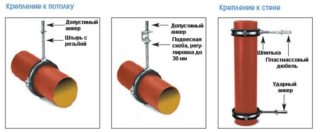

- Reliable fixation to the ceiling or wall. Plumbing lines are constantly under load, they are affected by vibration and temperature changes. Without reliable fastening, the pipeline can collapse. It should be checked that the hardware of the fasteners is firmly held in the supporting surfaces, without coloring and cracking.

If there is any doubt about the reliability of screwing the fastener, you will have to change the original pipeline design.

Step-by-step installation guide

- With the help of fasteners of fittings and joints, branches are laid to the heated area. The pipeline is rigidly fixed.

- Fixed floating support parts with expansion joints. They will protect the line from vibration and deformation even with possible linear expansion.

- After applying the center lines of the sewage system to the walls, a pipeline is laid. According to the marks, guide fasteners are placed, and the pipe is laid. The slope of the pipe sections and the number of fittings for the sewer system are also determined.

- Fittings are installed with support and crimp fasteners to avoid negative vibration and temperature effects.

- When installing a new system, the line is inserted into the clamping piece in the form of the letter "U" and applied to the collapsible tie. The bolt lock is tightened. Do not tighten the collapsible fasteners too tightly before the sewer system is completely installed.

- The supporting parts are mounted according to the number of joints and fittings. An empty section without fittings is fixed with guiding and protective clamps.

Even more reliably than clamps, the line is fixed in the groove, which acts as a channel for laying a pipe product. If you install the pipeline into a special channel in the wall, this will securely fix it and will not spoil the design of the room.

Modern fasteners are structurally adapted in order to mount them and the entire pipeline as a whole was not difficult. To install any type of mounts, you do not need the use of specialized tools or professional skills.