A reliable drainage system allows you to protect buildings and structures from the negative effects of excess moisture. For the installation of communications, plastic drainage trays with a lattice or gutters made of cast iron, concrete, polymer sandy materials are used. Each type has its own dimensions and specifications.

Definition and scope

The gutter is a gutter of a specific length. Its depth, height and width determine the throughput of the product. The top of the tray is covered with a protective grill.

Channels are used to construct a drainage system at such facilities:

- garden paths, park areas;

- highways, autobahns, city roads;

- port docks;

- airports;

- car washing stations;

- playgrounds;

- parking lots, parking lots.

Often, drainage gutters are used in industrial plants to remove contaminated wastewater into the city sewer system.

Device and material of manufacture

Storm runoff gutters are U-shaped or U-shaped. The height of the sides of such products is the same on both sides. The curb trays have an L-shaped edge ledge on one edge, which allows you to fix the gutter.

For trays that are installed in public places, upper grilles with a special locking mechanism are provided to be healed from vandals.

There are several types of gutters on the market for the installation of a drainage system. The most popular are:

- polymer;

- polymer sand;

- cast iron;

- reinforced concrete;

- polymer concrete.

Each of them is used in specific areas with different load intensities.

Polymer gutters

Plastic trays for storm sewers are in great demand from private craftsmen. Since their load class is not very high, gutters are mainly used in private households.

Thanks to the mineral additives included in the polymer composition, the trays can withstand aggressive environments and mechanical stress. Due to the perfectly smooth inner walls of the channels, the water leaves quickly. The service life of polymer gutters is 50 years or more. The weight is only 7-9 kg / piece, so one master can carry out the transportation and laying of the canals.

Common sizes of polymer gutters:

- width - 0.15-0.5 m;

- length - 1-1.5 m;

- the height of the sides - 0.79-0.6 m;

- section - 0.1 m.

A variety of polymer trays - polymer sand products. During production, a free-flowing mixture of fine fractions is added to the plastic mass. Troughs are made by pressing. The result is a durable product that is resistant to mechanical pressure and static / dynamic loads.

Polymer sand tray can be used at temperatures from -50 degrees to +120. At the same time, he responds well to aggressive environments. The load class of such products is C250, so they can be used not only in private construction, but also in urban facilities. The main advantage is the low weight of the gutters. The master will cope with the stormwater device in one hand.

Cast iron trays

This type of metal has a high resistance to longitudinal and lateral loads; therefore, cast iron trays are more often used in places with maximum load - airports, seaports, parking lots, runways. For the resistance of cast iron to corrosion, it is additionally galvanized. In private plots, the use of such gutters is impractical due to their high cost. Typical dimensions of cast iron trays:

- width - up to 0.2 m;

- length - up to 0.5 m;

- internal section - from 100 mm.

Sometimes the length of the cast-iron channel is made slightly larger at the special request of the customer.

Concrete, polymer concrete gutters

Even 20 years ago, manufacturers made drainage trays exclusively from reinforced concrete. The products had a lot of weight, a relatively smooth inner surface of the walls, and were resistant to mechanical stress and corrosive environments. Special equipment was required for the installation of a concrete shower.

In order to significantly reduce the weight of one product and at the same time increase its resistance to static / dynamic loads, polymers were added to the concrete mass during the production of the tray. As a result, the gutters turned out to be many times lighter and stronger. Their inner walls are perfectly smooth. Such polymer concrete channels last up to 30-40 years, can be operated in a wide temperature range, and are resistant to longitudinal and transverse loads. They are often used both in suburban construction and in the installation of storm water in urban facilities. Dimensions of concrete, polymer concrete channels:

- width - 0.43-0.14 m;

- length - 0.5-4 m;

- wall height - 0.15-0.87 m;

- internal section - from DN 100.

Thanks to the improvement of technologies for the production of polymer concrete gutters, their load class can reach F900.

Types of grids for trays

The upper protective grilles for drainage channels are made of galvanized steel (stainless steel), cast iron or polymer sand composition. They all differ in size, slit shape, and color. More often they make black lattices or steel shades.

By design, the following types of products are distinguished:

- slotted - has a longitudinal slot for water to enter the tray;

- cellular - equipped with transverse slots;

- wavy - the slots are arranged in waves from one and the other edges of the lattice.

The design of the products does not in any way affect their throughput.

Criterias of choice

The selection of channels for the installation of a stormwater must be done based on the following parameters:

- Throughput of trays. Calculated based on the type of coverage on the site, the average amount of precipitation in the region for the year. It is advisable to multiply the obtained results by another 25% in order to have a safety margin.

- Load class. It is impractical to install high-class cast-iron gutters on a private area, as well as on complex objects with high traffic - polymer trays.

- Protective grille type. It can be with or without a locking mechanism. The upper grille is also matched to the load class.

It is important to consider the total length of the storm sewer. This will help you buy the right number of trays.

Installation rules

When installing drainage gutters, experts advise adhering to the following rules:

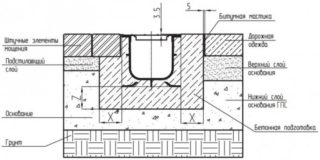

- The trays are always placed on a special sand cushion. Concrete products are mounted on a pre-poured layer of mortar.

- It is important to observe the slope of the rainfall at the rate of 10 mm for each running meter. This will ensure the free flow of water away from the object.

- It is advisable to install sand traps. They prevent silting up of the system.

- The upper grilles must be fixed.

In order for the storm drain to work properly, it is necessary to clean it regularly. To do this, once or twice a season, the upper grates are raised and the debris accumulated inside is removed.

Cost of drainage trays

Prices for a drain drainage tray vary depending on the material of manufacture and the internal section.The approximate minimum cost of gutters for the Moscow region:

| Item type | Price |

| Plastic drainage tray Hydrolic | From 240 rubles / piece |

| Polymer sandy | From 330 rubles / piece |

| Concrete | From 3 700 rubles / piece |

| Polymer concrete | From 740 rub./pcs. |

| Cast iron | From 2 200 rubles / piece |

In general, for a suburban area it is more profitable and more convenient to use polymer gutters to drain stormwater.