Sewer couplings are fittings for connecting socketless pipe sections in sewage systems. They ensure the tightness and strength of the pipeline at the joints. With the help of couplings, you can assemble a new line and repair damaged sections of existing sewage networks.

Application area

Depending on the scope of use, coupling products are classified as connecting, repair and fire protection. The former are subdivided into three types:

- transitional products for the installation of an internal sewer network;

- connecting elements used when creating an external pipeline;

- compensation inserts.

The latter are used in all types of pipelines where it is necessary to neutralize linear expansion. Dismantling inserts compensate for this by adjusting the stroke length.

The connection of the toilet bowl to the sewer outlet is often performed using a special cuff, which is corrugated in production. This allows you to give it flexibility and save space in the bathroom.

Fireproof couplings prevent the spread of open flames along the main pipes. Outwardly, this device looks like a metal cylinder with a special liner. The latter is made of a fire-resistant material that swells under the influence of high temperatures. Due to this, the clutch seals the line during a fire, preventing further advancement of flame and smoke. Installation of fire protection elements is required on all polymer mains of the building.

Fittings are fixed to load-bearing walls or ceilings. Their installation is quite easy, it can be done at any stage of construction and installation work.

The slip-on repair coupling is longer than conventional connection elements and is used to replace damaged parts of main pipes, as well as to install additional fittings. Sometimes, instead, repair work is carried out using an expansion pipe in combination with a sewer coupling.

Classification of sewer couplings by type of connection

Shaped elements are subdivided as follows:

- With threaded joint. It is used to create small cross-section drainage systems. Often, this type of connection is installed on pipes under the sink in the kitchen or the sink in the bathroom.

- With rubber O-ring. Most often used in highways for wastewater disposal. Advantages - quick and easy installation without the use of special tools or additional materials.

- On glue. In this case, there is no thread on the coupling or a special rubber seal. Tightness at the joints of the parts is achieved through the use of a special adhesive. Fastening of pipe sections to glue is not allowed to be used in sagging places of the pipeline.

The most durable type of connection is welding. Can be used for pipes made of metal and plastic. The downside is the need to use special equipment. This limits the use of this docking method at home.

Manufacturing materials

Shaped elements are created from plastic and metal: cast iron, steel, brass, copper.Steel products and models that are made of non-ferrous metals are rarely used at home due to their high cost.

The cast iron element is a wide split clamp with a rubber gasket. For installation, it is disconnected, put on the damaged area and tightened with bolts.

Plastic models are selected depending on the material of the main pipes. They can be polyvinyl chloride, polypropylene or made of low pressure polyethylene (HDPE). Most often, PVC pipes and corresponding fittings are used for the installation of home networks. They have many advantages:

- Resistance to aggressive environmental influences, rust and temperature extremes.

- Safety for humans and the environment.

- Durability. If the operating conditions are followed, the pipes can last more than half a century.

- Significant bandwidth. Smooth inner walls reduce the possibility of congestion.

Low weight facilitates transportation and installation: no need to use heavy vehicles and special equipment, which significantly reduces costs. The elements themselves are cheaper than any other counterparts.

Separately, it is worth mentioning the rubber sewer coupling. It is used to connect system parts made of different materials, for example, polymer and cast iron.

Size range

Fittings are available in various sizes: they correspond to the cross-section of the abutting pipeline sections. The most popular couplings are for sewer pipes with a diameter of 50 and 110 mm. But other options are used if necessary.

Correspondence of dimensions - length and section - of a transitional sewer coupling in millimeters:

| Sewer network type | Cross section | Length |

| Outdoor | 110 | 117,3 |

| 160 | 147,8 | |

| Internal | 50 | 87,1 |

| 110 | 113,7 |

Elements of repair couplings for internal sewerage have similar dimensional characteristics.

The overall ratios of push-in fittings for outdoor installation are different:

- The length of products with a section of 110 mm - 12.2 cm;

- 160 mm - 17.2 cm;

- 200 mm - 21.2 cm;

- 250 mm - 25 cm;

- 315 mm - 29.3 cm;

- 400 mm - 32.4 cm;

- 500 mm - 36.2 cm.

When connecting cuffs with other fittings, the section is not taken into account of the pipe sections themselves, but the branch of the tee or cross. Its diameter may differ from the size of the main line.

Installation work rules

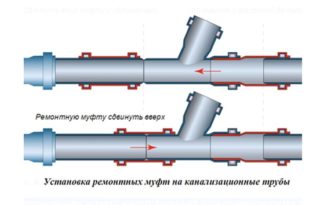

Installation of repair elements

The work is carried out in the following order:

- The pipe is cut in the right place or the damaged part is cut out.

- A repair sleeve is put on the lower piece of the pipe. Its outer cut must be pushed in until it is flush with the pipe end.

- A sleeve with a longer bell is put on the upper end in a similar way.

- An intact pipe section or the desired fitting is inserted between the fitting elements.

- The sleeve with an elongated socket is moved down, and the repair one - up, making the connection of all parts into one whole.

The part of the pipe installed between the couplings requires machining. To do this, a chamfer is removed at the ends, then they are covered with technical grease. This ensures that the system will not leak after repairs.

In difficult cases, it is worth using a silicone sealant by pumping it d end parts of the couplings. After the composition has dried, the likelihood of leaks is reduced to zero.

The nuances of working with cast iron couplings

- The pipes and the fitting are set in the desired position.

- Parts are fixed with clamps.

- A hemp strand impregnated with a bitumen composition is placed in the bell, with each coil being stamped, or a graphite gland.

Externally, the socket is sealed with cement or a cement-sand mixture in a 1: 1 ratio.

Installation of sealing collars

- The cuff is put on a smaller pipe section.

- The wide part of the shaped element is wrapped around the narrow one.

- The connected elements are put into working position.

- The wide part of the cuff is unfolded so that it wraps around the narrow one.

Before putting on the cuffs, the mating parts must be cleaned of any contamination. With an uneven socket surface, the sealing part is mounted using silicone sealant.

Modern fittings are very easy to install and do not require specialized equipment. When choosing any type of couplings, you need to check that there are no cracks on their surface, especially at the ends. In the presence of chips, it is impossible to achieve the tightness of the line for drainage of wastewater.