If a small sewer blockage is removed with a plunger, then more serious devices will be required to fully clean the line. Washing machines consist of a high-power pump and a flexible hose, at the end of which special nozzles are installed. They help break up and soften hard, stagnant deposits.

Definition and purpose of nozzles

Sewer flushing nozzles are used in the hydrodynamic method of pipeline cleaning. They are connected to the hose of a powerful apparatus introduced into the drain hole, which, under high water pressure, is able to remove plaque from the inner surfaces of the pipes and remove even solid blockages and nitrous oxide.

Previously, this technique was only the final stage after cleaning with a cable, but now, thanks to powerful pumps, you can do without mechanics.

This method is optimal for plastic lines, since it minimizes the risk of damage to the pipe walls.

For work, special-purpose hydrodynamic devices and car washes are used. Nozzles that make flushing more efficient are connected to both devices.

Types of products

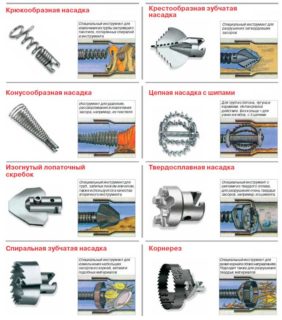

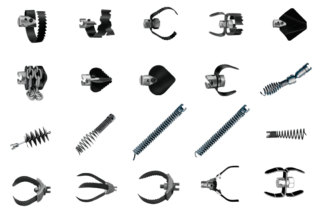

Flushing nozzles are subdivided according to design features and depending on the nature and location of the blockage.

Separation according to the principle of action

A blockage in sewer lines is formed from substances with different compositions and is concentrated in different sections of the pipe. Depending on this, after teleinspection, an element is selected that can remove the obstacle most effectively. He can be:

- bottom - used to eliminate sand, silt and mud, most often settling on the bottom of the pipe;

- rotary - removing fatty deposits from the walls due to rotation (the higher the speed, the more effective cleaning);

- punchy - capable of removing the toughest blockages;

- chain-carousel - coping with compressed sediments.

There are also universal nozzles suitable for all types of blockages.

Classification by construction

- Straight. They are suitable for primary punching of corks, since they allow you to drag large residues of paper, fabric, food through to the exit.

- Pear-shaped. Used to clean where there are bends.

- Triangular. Remove dense obstructions by sawing, cutting and drilling.

- Pomegranate. They are used for complex cleaning of mains with a cross section of up to 300 mm under high pressure.

- Parts with skids. Thanks to the nozzles, they can cut roots, fat and mineral deposits.

- Wedge-shaped. Bottom nozzles usually come in this shape. They are chosen not only for cleaning sand and silt, but also for processing large highways and moving heavy residues.

Steel cutters for cleaning sewer pipes are also effective. They are equipped with replaceable ceramic heads. Due to the high rotation speed (6000 rpm), such parts save the pipeline in emergency conditions. Rapid insertion of the cutter into the congestion formed by roots, dirt and grease leads to its delamination and further washout with a water jet in the shortest possible time.

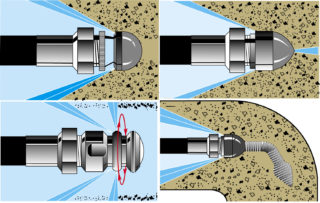

The principle of operation of units with nozzles

In the process of cleaning the sewage system, the high pressure water flow destroys and removes sediments. The nozzles enhance the action by breaking dense or prying off slippery layers of blockage.

The equipment is selected depending on the length of the communication line, the presence of branches and the maximum cross-section of pipe sections.

In order to flush the pipeline using hydrodynamic equipment with nozzles, the degree of clogging and the location of the main plug are first determined by a mechanical or tele-inspection method. To make this possible, during the installation of the sewage system, inspection hatches and inspection wells are installed. Revisions must necessarily be at the sections where pipe sections are connected.

Then they work with hydraulic equipment:

- They regulate the pressure indicators that are suitable for a particular branch of the line. If it is a private house or apartment, it should not exceed 150 bar. If the head is excessive, there is a risk of injury to the pipe walls up to rupture. In industrial environments, where strong communications are installed, the pressure can be higher.

- Install a suitable nozzle depending on the type of blockage and its location. You also need to take into account the tortuosity of the highway section.

- The hose is lowered into the inspection hole and carefully advanced along the branch.

During the procedure, the cleaning stream is sprayed at different angles, the plug breaks up and the inner surfaces are cleaned. Thanks to the flexibility of the hose piece and the use of a suitable nozzle, the hydraulic device perfectly flushes the turning zones of the communications.

In case of severe blockages, if the advancement of the hose is unrealistic, it is pulled out. The packing element is replaced with a more powerful version, the pressure is increased as much as possible. After removing the problem, the hose is gently pulled out, the inspection hole is closed.

The nuances of flushing home sewage

Home sewer flushing systems are easy to operate and include a manual. It details the steps for using the device. However, there are nuances, the knowledge of which will help a beginner to effectively cope with the task:

- The holes on the attachment elements are located so that jet thrust is generated. It gives movement to the hose, so there is no need to push it hard.

- After entering the sewer system, the flexible element is carefully moved in the direction of the riser.

- The hose is introduced not only into the inspection hatch, but also into the drain hole of the toilet bowl or sink.

- After removing the blockage, the pipes are rinsed with a stream of hot water. It's a good idea to add a disinfectant detergent.

- The hose part is removed from the pipeline only after the device is turned off.

Devices for cleaning the pipeline are used for preventive cleanings and in the event of an accident. If you decide to buy such equipment, focus on the length and diameter of the line, and when choosing nozzles, take into account the material from which the pipes are made. This will allow you to save money, because more powerful units are more expensive.

It is advantageous to buy attachments as a set, so that the necessary element is always at hand. Get telediagnostic video equipment to detect blockages faster.

With the right approach and choice of hydraulic engineering and nozzles, blockages of any complexity are eliminated without the involvement of professionals.