A cesspool is the simplest sump for sewage and sewage. He has one drawback - the pit will have to be cleaned periodically so that it does not overflow. They use three ways: they invite a sewer truck, they clean it with buckets or use a fecal pump for septic tanks and cesspools.

Purpose of pumps

Sewage waste is a mixture of water with sewage that settles to the bottom of the sump and is present in the form of suspended particles throughout the entire water volume. At the same time, the bottom of the pit is gradually silted up with a thick layer, which can only be pumped by a fecal pump.

The technical characteristics of the device are not only about power and head. They have one parameter that other pumping units do not have. This is the ability to pump liquids containing solid impurities inside. At the same time, for pumps for wastewater and cesspools, this parameter varies from 5 to 50 mm. This is important because untreated sewage contains hair, organic matter in the form of food waste, small objects, sand and pebbles.

Installations are used not only for pumping out drain pits, but also for draining basements, pumping sewage in a pressure sewer, for draining suburban areas, emptying pools and other reservoirs.

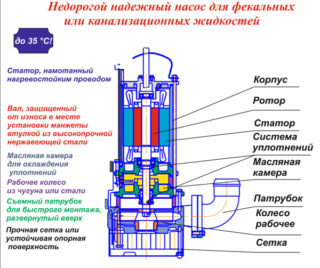

Device and principle of operation

The pump itself belongs to the category of centrifugal. The impeller, mounted on the shaft of the electric motor, rotates at a high speed (up to 3000 rpm), throwing the pumped medium to the walls of the chamber. It is in this place that a large pressure of drains is created, which must move somewhere. Otherwise, the pump chamber housing will simply rupture. For this, a hole is made on the side, connected to the branch pipe. Through it and the pipe connected to it, the drains move further. Usually this is a sewer system, an intermediate tank or a disposal area.

On the contrary, a low pressure zone forms in the middle of the impeller. An inlet pipe is also located here, through which dirty water is drawn into the alluvial installation.

To prevent large pieces and objects from getting inside the device, a grinder is installed on the shaft in front of the impeller. These are knives that cut everything that comes under them.

Types of fecal pumps

The classification of mud pumps includes three types. They do not differ from each other purely constructively. But each of them has its own characteristics:

- submersible;

- semi-submersible;

- superficial.

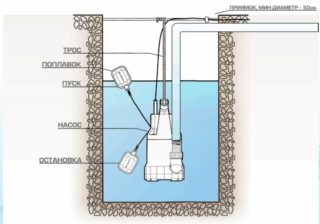

The submersible modification differs from the others in that such pumps are immersed directly into dirty water. They are installed at the bottom of the tank, pulling out a hose or pipe connected to the outlet pipe to the surface. They are equipped with floats that automatically turn on or off the device. For example, if the float rises as much as possible, that is, the sump is filled, the pump immediately turns on for pumping. As soon as the float has dropped, that is, the water level has dropped to the maximum, the pumping unit is turned off.

Features of submersible pumps:

- increased power;

- 100% tightness of joints of units and parts;

- the cooling of the electric motor is carried out by the liquid in the cesspool, therefore, its temperature should not exceed + 40C;

- lower the unit into a hole on a cable, which is tied to an eyelet on the body;

- once every three months the pump is lifted and the shredder is cleaned, which is often clogged with fine particles.

The prices for submersible pumps for pumping out a cesspool are the most expensive, because such a unit is assembled from materials that can withstand the loads of an aggressive environment, plus the connection of the nodes requires complete sealing of the joints.

Semi-submersible models

The pumps are installed in drain pits without being completely immersed in dirty water. Below the level, there is a discharge chamber, in which the impeller is located, above the level, there is a compartment with an electric motor. Therefore, a fan is mounted on the latter, which provides cooling of the device.

For the installation of semi-submersible pumps in the cesspools, a platform is constructed from a metal profile. This arrangement makes it possible to hear how the motor works. If the sound of the noise has changed, then the device itself is not working properly or under heavy load. You can quickly react and prevent equipment failure.

Semi-submersible models are cheaper than submersible ones. The reason is the cheaper materials used in the assembly, and not the most stringent requirements for sealing joints and joints.

Surface installations

The pumps are installed next to the cesspools. They are not immersed in water, so the units are low-powered. A hose is lowered into the pit itself, which goes to the device as a complete set. Its length is 7 m.

Manufacturers offer conventional pumping units, into which water is poured to raise contaminated sewage liquid. Another modification is self-priming pumps. To raise drains from the pit, they do not need additional filling with water. The rotation of the impeller in a sealed casing creates a vacuum, which draws the liquid into the pump.

The convenience of using surface modifications is that they are in plain sight all the time. Any change in the operation of the unit can be monitored and quickly responded. Therefore, these fecal pumps run longer than others.

Surface sludge pumps can be installed where solids in the sewage do not exceed 5 mm.

What are the criteria to choose

The classification of pumps for fecal pits includes several subsections. The first is domestic or industrial pumps. They differ from each other in power and pressure. In households, both characteristics are much lower.

If the task is to ensure the pumping of a cesspool at a summer cottage, the following criteria must be taken into account when choosing a pump:

- power, - for how long and how much waste the pump can pump;

- the head of the device - to what height the pumping unit can raise the drains;

- temperature of the pumped-over medium;

- aggressiveness of the environment;

- material from which the unit is made;

- presence / absence in the design of the grinder.

It is better to give preference to models with chopping knives. Taking into account the volume of the pit, it is necessary to choose the power of the unit.

How much do fecal pumps cost

The range of prices is large, because this indicator depends on the technical characteristics and the model. For instance:

- brand GS400 (submersible) from Jemix with a capacity of 7.5 m³ / h, a lifting height of 5 m and the ability to pass particles up to 35 mm through itself costs 2000 rubles;

- the Espa Drainex 300M brand with a capacity of 34 m³ / h, with a lifting height of 7 m, which allows particles up to 50 mm to pass through, the version is made of stainless steel, costs 44,000 rubles.

Also, the price component differs from each other submersible, semi-submersible and surface pumps. The former are the most expensive.