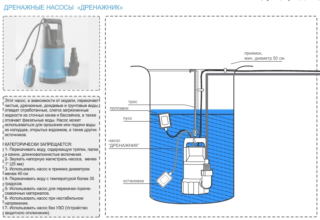

Submersible pumps of the Drenazhnik series are produced by the well-known Russian brand "Dzhileks". The entire range of pressure equipment is suitable for pumping contaminated liquid with an abundance of impurities. But each model has its own design features.

Principle of operation and device

The scope of use of such pressure installations is wide enough. They are used to pump water from the following sources:

- polluted pools;

- pits;

- wells;

- basements and cellars;

- sewage pits with low density liquid;

- for watering a vegetable garden and a garden from wells and ponds.

All submersible pump models do not differ much in design. The parts of the devices are under the sealed protection of the cylindrical body. Its inner part is divided into two compartments: engine and work. The first chamber houses an electric motor, which consists of a rotor, stator and self-lubricating bearings. A special temperature sensor is built into the winding of the electric motor, which turns off the device if the engine overheats significantly.

An impeller with blades made of a special polymer alloy and a diffuser are installed in the working compartment. It receives liquid after acceleration by the impeller. The pumps are equipped with float mechanisms that stop the device when the water level drops.

Model range and technical characteristics

The line of Drainers includes six devices, with an immersion depth of up to 8 m:

| Model | Productivity (l / min) | Power, W) | Water supply (m) | Dignity |

| 110/6 | 110 | 200 | 6 | Auto shut-off when the liquid level in the working compartment drops to 15 cm. |

| 170/9 | 170 | 670 | 9 | High motor power for a small device. |

| 200/25 | 200 | 1200 | 25 | Longest distance for pumping water. The outlet is located on the top instead of the diffuser. |

| 220/14 | 220 | 750 | 14 | Automatic shutdown system. Possibility of pumping out inclusions up to 6 mm. |

| 350/17 | 350 | 1200 | 17 | Coarse-mesh inlet grate, which allows large solids to be pumped. |

| 550/14 | 550 | 2000 | 14 | The powerful electric motor is capable of pumping water with solids up to 40 mm in size. |

In addition to the six models presented, there are three more modified pumps in the "Drainer" line. By design, they are similar to the main units, but are used for pumping fecal matter.

The minimum capacity among them is the model 150 6 lbs. It is a faecal drainage pump with a plastic casing and a float protection mechanism. Designed for pumping large particles from septic tanks, cesspools and toilets. The permissible size of fractions is 35 mm. Works at a speed of 150 l / min. Its counterpart in a stainless steel case is the Drainer Unit 150 7 lb.

The Productivity Leader in the Drainer range is 255 11 lb. It is capable of pumping liquid at a speed of 255 l / min and transmitting water under pressure over a distance of 11 m. Equipped with an electric motor with a power of 1100 watts specified by the manufacturer.

The choice of pump depends on the operating conditions: pumping out melt water from the basement or water intake for irrigation. It is done on the basis of the design indicators of the models.

Features of pressure equipment

Of the minuses, one can note the limitation on the temperature of the pumped liquid: only in the range from zero to 35 degrees Celsius. This should be taken into account if the pump is used for pumping water, for example, in case of a breakthrough on the DHW line. It is necessary to wait a while for it to cool down.

Periodic cleaning is required for the pump to last for a long time. To do this, it should be disassembled, after drying well and cleaning the outer part of the case:

- Loosen the screws that connect the case. This is done evenly.

- Remove the housing cover together with the screws, carefully take out the rubberized gasket and disconnect the float protection.

- Step by step dismantle the impeller with the rotor and the motor.

After disassembly, the pump is flushed from dirt, sludge and other particles. After that, it is thoroughly dried and assembled in the reverse order.

The overall functionality and operating period of the pump can be significantly increased by installing an additional filter element on it. It will filter the liquid entering the nozzle, due to which the cleaning of the apparatus parts will be postponed for a longer period.