In modern buildings, the internal sewerage system is assembled from plastic pipes. They have a number of advantages and are easier to install, since there is a wide variety of fittings that allow you to make turns, connections and transitions from one diameter to another. The problem of replacing old rusted elements with polymer products is solved in a completely different way. In this case, an adapter for a cast-iron sewer pipe is needed, with which it will be possible to dock the plastic with the metal.

Definition and purpose of the sewer taper

Cast iron to plastic adapters serve two purposes: they connect elements of different diameters and from different materials. They are used in external and internal sewerage systems. By design, they are divided into 2 types:

- concentric, connecting vertical risers;

- eccentric, serving in horizontal connections.

Plastic transitions, depending on the purpose, have a different design:

- Couplings are used to join products of the same size. They are made in the form of a barrel, the inner diameter of which corresponds to the outer section of the pipes.

- Angles with 45 - 90 degree turns with a thread on one side.

- Tees and crosses that allow wiring of various configurations with different diameters.

- Contours - The shape of the product helps to go around the pipe obstacle to reduce the number of elements.

- Compensators withstand water hammer and temperature drops.

The connection of plastic adapters is carried out by welding, threading, gluing, using elastic seals.

To quickly connect polymer pipes to cast iron wiring, rubber or polypropylene cuffs are used for external and internal connections. In the presence of a metal socket, an adapter is inserted into it, the outer section of which corresponds to the inner diameter of the expansion of the pipeline element, therefore, the use of sealant is not required. If there is no funnel, you will have to use an outer cuff.

Manufacturing material

Various raw materials are used for adapters:

- cast iron;

- steel;

- polypropylene;

- polyvinyl chloride;

- rubber.

Modern fittings made of gray cast iron are coated with a bitumen mixture, which protects pipes from corrosion and cracking at temperature extremes. The durability of the products allows them to be reused. They combine well with all kinds of plastic products. The disadvantage is the large weight of the structure.

PVC adapters connect pipes of any configuration from plumbing to the outlet in the riser. Products allow you to connect and change the direction of flow, change from one pipe size to another. Polyvinyl chloride can withstand temperatures up to 60 degrees and is resistant to dissolved chemicals.

Polypropylene has a number of advantages over other materials used. The polymer can withstand temperatures of 80 degrees, for a short time within one minute - 95 degrees. In the effluent, an acid-base balance of pH from 2 to 12 is allowed. However, before installation, it is necessary to check the products for stability in specific conditions. Polypropylene adapters are corrosion resistant and lightweight.The material withstands shock loads well.

Product dimensions

Plastic tappers have the following running diameters:

- 50/75;

- 110/124;

- 50/75 with cuff;

- 50/72 with gasket;

- 110/124 with seal;

- 110/125 with gasket;

Polypropylene:

- transitional cuff: 50/32/50;

- taper 50/75 with 2 sets of sealant.

Rubber transition:

- 50/32 for connecting washing machines;

- 50/40;

Elastic products withstand temperature changes and retain the material's ability to stretch from 0 to 72 degrees.

Installation rules

Experts do not recommend using silicone, linen cables or sealants when joining plastic products. They are successfully replaced by rubber sealing rings. If leaks appear after installation, the skewed ring should be corrected.

Elastic seals have a rather high rigidity, therefore, difficulties arise during installation. In this case, the end on which the seal is put on is coated with a liquid detergent.

Rubber cuff

If the old pipe is easily pulled out of the socket and the integrity of the cast-iron surface is preserved, the end of the plastic pipe is inserted into the extension by 3 or 8 cm. A quick and high-quality connection can last 8 years.

For plumbing fixtures that are located close to each other, there are 2 outputs to the riser. One with a diameter of 100 mm is used when connecting drains from a bidet and toilet, the second - with a diameter of 50 mm, for sinks, bathtubs and showers.

Algorithm for attaching polymer wiring to a cast-iron socket:

- the inside of the cuff is cleaned of rust and dirt;

- to prevent leaks, a sealant is applied to the outside of the rubber product;

- insert tapes.

At the last stage, a connection with a polymer pipe is carried out.

Plastic fitting

Sewer adapters from cast iron to plastic are used in cases where the cut of the metal pipe does not have a socket. In addition, cast products often have diameters other than the standard, for example 60 mm. The connection is made with a 50/72 mm taper.

According to the scheme, the assembly looks like this: a plastic pipe, a 50/50 coupling, a rubber ring, the adapter itself 50/72, an elastic cuff, a seal, a cast iron pipeline d 60 mm.

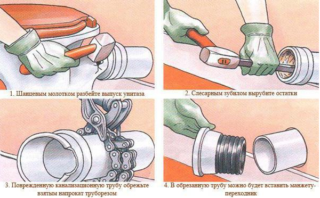

Procedure:

- the old metal pipe is cut exactly;

- a rubber cuff is put on the stripped end;

- apply sealant to its inner edge and the top of the plastic fitting;

- insert the adapter into the seal.

It remains to insert a polymer pipe into the prepared end through the coupling. The size of the cuff and taper must match.

Caulking with asbestos cord

The method is used when joining cast iron products, since the configurations of cast fittings are limited. Operating procedure:

- the rope is wound on plastic;

- the wrapped end of the pipe is inserted into the cleaned hole, helping to close the cracks with asbestos material with a screwdriver;

- prepare a solution from water, cement and PVA glue;

- coat the joint with a cementitious compound.

It is recommended to wait a day to dry before using the sewage system. This method is highly reliable and guarantees leak-free operation for a long time. This is how cast iron sinks are connected to a plastic pipeline.

If the pipes have different diameters and the gap between them is large, in addition to the winding, a rubber gasket is inserted. Construction silicone can be used instead of mortar.