During mechanical cleaning of the sewage system, the blockage is pierced in a certain area. But on the walls of the pipeline there is a constant settling of solid particles, the inner passage narrows, plugs appear much more often. The hydrodynamic method of cleaning the highways solves this problem.

Hydrodynamic engineering

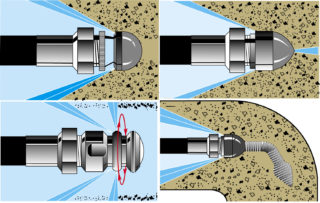

Inside the pipeline, such a "projectile" moves with the help of jet thrust. Behind the nozzle there is a row of nozzles that are directed backwards to the advance of the hose. When the water is turned on, the nozzle begins to move like a rocket.

Moving along the pipe, the nozzle with nozzles knocks down all growths. The attachments vary in size and function. Their choice depends on the cross-section of the pipeline, the type of sewer communications and how clogged they are. For example, to eliminate traffic jams and congestions, a breakdown nozzle is installed, and a rotary nozzle is used for preventive cleaning of storm sewers. The principle of operation is the same for any hydromechanical equipment, regardless of size and power indicators.

Hydrodynamic flushing is universal, it is used for both external and internal sewerage systems. It has a complex effect on the system from the inside, allows you to destroy and eliminate all blockages and mud build-ups, including plant roots, sometimes growing into sewer communications.

Hydraulic flushing installation device

- powerful pumping equipment;

- drive - electric or gasoline;

- high pressure hose;

- the tip on which the nozzle is installed (spray nozzle).

For a hydrodynamic device, a pump is required that creates a high pressure (about 200 MPa). Earlier, devices of similar power were bulky and weighed a lot. Today, the units are lifting and compact.

Each nozzle (spray nozzle) is selected for a specific purpose. Any nozzle is designed so that during operation it moves forward due to a strong ejection of water jets in the opposite direction. This technical solution contributes to the independent movement of the hose through the pipe and cleaning.

The nozzle is connected to the pump using a flexible hose. This method of joining allows you to clean pipes of any design, even multi-level complexes.

Equipment options

The choice of installation is made depending on several main indicators:

- Section of the pipeline. For domestic sewage systems, equipment is usually used that allows you to clean pipes with a diameter of 50-250 mm. Such units are portable or have wheels.

- Length of the line between two inspection chambers. The shortest working hose is 15 m, but the complete set of professional equipment often includes flexible elements 30 m long.

- The purpose of the unit is for personal use or industrial use.

Household and industrial devices are similar in design.The former are distinguished by low power indicators. They are intended for servicing pipelines with a cross section of 25–350 mm. They are used for indoor sewerage systems.

Special machines - units with powerful pumps - are used to flush pipelines with a cross section of more than 350 mm. Recommended for external sewerage and communication lines operated in difficult conditions.

Domestic installations and industrial devices are divided into two types, depending on the power source. In independent devices with internal combustion engines, the pressure can reach 500 atmospheres, which allows for high equipment productivity. Cleaning of a pipeline of any cross-section is possible. Installations with three-phase AC motors are used for flushing systems with a cross section of no more than 200 mm.

When buying a hydrodynamic device, you need to remember that hose extension is not recommended: when working under high pressure, it can break at the junction. It is better to immediately buy a flexible element of the required length.

It is not necessary to buy a separate installation for self-flushing of pipes. The Karcher car wash unit will cope with this job. But the manual for the selected model should mention this feature. The device in the basic configuration can be supplied without attachments, they will have to be purchased separately.

Cleaning technology

Hydrodynamic cleaning of sewer pipelines is carried out in the following order:

- A suitable nozzle is selected depending on the type of blockage. If it is a preventive cleaning, it is better to use a rotary or universal element. In emergency situations, punchy models are used.

- The installation is going to - the nozzle is connected to a flexible element, and that is connected to the working equipment.

- A hose end is inserted into the pipeline at the section of the pipeline where the drain or inspection hatches are equipped as close as possible to the possible place of blockage. The depth to which the nozzle is immersed is approximately 50–70 cm.

- When the hose is inserted, the pump turns on. It is not necessary to start it in advance, as the water jet under pressure can injure the operator.

After starting the installation works automatically. The cleaner only needs to control the movement of the hose. As you move along the path, obstacles will come across, but the nozzle crushes them. When the blockage has completely collapsed, pull out the hose and clean it of dirt.

The last step will be to flush the sewer line with plenty of water. One procedure is enough to restore the required bandwidth of the backbone. But for greater reliability, flushing is performed a couple more times. After cleaning is completed, the water supplied by the device is simply drained into the sewer system, the pipeline remains absolutely clean, ready for use.

Advantages and disadvantages of the method

- The quality of the cleansing. Mud build-ups of any size and degree of compaction are removed.

- Suitable for use in winding pipelines due to the use of a flexible hose.

- Speed. Washing even long communication lines is carried out promptly.

- Use in any weather. Cleaning efficiency does not decrease, even if the thermometer has dropped significantly below zero. Hydraulic flushing breaks and eliminates ice plugs formed when pipes freeze.

- Safe for the environment. Only water is used to punch sewer lines. No need for damaging chemicals. Thanks to this, the cleaning does not pose any danger either to the pipeline, or to people and animals.

- Reduced risk of re-clogging.As practice has shown, high-quality hydrotreating of the pipeline several times reduces the likelihood of new blockages: the pipes from the inside after washing become so smooth that the sediment appears on them much slower than before cleaning.

The technique is not limited in its application. It is suitable for any type of pipelines, regardless of their configuration, material of manufacture and the principle of laying.

The main disadvantage of this method is its high cost. This also applies to the purchase of hydraulic equipment for self-cleaning of pipelines, and ordering professional services. Prices for cleaning the sewage system by a hydrodynamic method start at 110 rubles per running meter of the pipeline. The cost of the cheapest car is about 30,000 rubles.

Hydromechanical flushing is effective and does not damage the system. It is even suitable for sewer lines, the dilapidated state of which does not allow cleaning by mechanical or chemical methods.