The sewer system becomes clogged over time. The reason for this may be operational debris arising from the deposition of fatty particles on the walls of the pipeline, which create a conglomerate of sand and household waste. In other cases, the cause of clogging may be improper installation: non-observance of the slope, the wrong choice of the diameter of the elements of the drainage system, the appearance of rust and the roughness of cast-iron pipes.

Appointment of a sewer audit

When removing the trash plug that blocked the section, an audit of the sewer riser is used. Purpose of the device: to provide access for quick removal of the blockage using ropes or steel wire, which allow you to break through the obstacle and clean the drains without disassembling the pipeline.

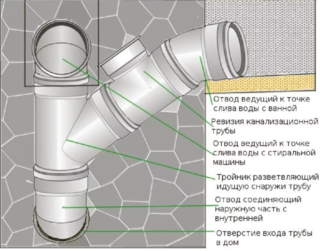

The element is a part of a pipe in the form of a tee, which has an opening with a closing lid, through which stuck debris is removed using various devices. The audit is installed inside or outside the house. If, for some reason, they forgot about the inspection hatch during the installation of the sewage system, cleaning will require dismantling or damage to the pipeline, as a result of which leaks and an unpleasant smell appear in the living room.

Installation guidelines

Installation of the audit is provided for by SNiP 2.04.01-85. In panel houses, hatches are installed after 3 spans; in a five-storey building, their location in a vertical riser is limited to the first, third and fifth floors.

On horizontal sections, the elements are arranged at a distance of 8 or 10 m, as well as at turns and forks. Revisions with a diameter of 50 mm are installed on clean industrial wastewaters every 15 m, on household pipelines - after 12 m, on polluted industrial waters - with sections of 10 m.For elements with a diameter of 110 mm, under the same conditions, distances are accepted: 15, 20 and 12 m.

They do not suit inspection hatches in sewer pipes running under the ceiling of the corridor and in risers passing through public catering places.

Dimensions and material

The revision is selected from raw materials corresponding to the internal wiring. There are two types of products in use:

- Cast iron - have 4 bolts for fastening the hatch door, which can only be unscrewed with keys.

- Plastic - with a threaded lid that is easy to open by hand.

Polymer products are more popular. Unlike cast iron pipes, they have a smooth inner surface, are easy to install, do not corrode and are resistant to weakly alkaline and weakly acidic compounds. They are not afraid of temperature drops, products are frost-resistant and do not need painting.

Pipes made of polyvinyl chloride and polypropylene have sockets on one side, with the help of which they are easily connected to each other. Fittings of various configurations are used to make turns, connections, repairs and transitions from one section to another. Each type of plastic has its own characteristics, which you need to know about in order to make the right choice.

Advantages and disadvantages of polyvinyl chloride revision

The polymer is made from ethylene and combined chlorine derived from salt. It has a number of advantages:

- long service life;

- a light weight;

- easy installation;

- resistance to sunlight and aggressive compounds.

Disadvantages of PVC products:

- high heat capacity of the material, which ensures rapid cooling of waste streams;

- fragility appearing at 0 degrees;

- when burning, poisonous gas is released.

It is impossible to attach plastic products to metal pipes, as the polymer hardly tolerates mechanical influences, for example, threads.

Advantages and disadvantages of polypropylene revision

The main advantages of products are elasticity, lightness and strength, smooth and non-oxidizable surfaces. The disadvantages are high flammability, destruction under ultraviolet radiation and significant expansion when exposed to high temperatures.

Revisions with a diameter of 50 mm and a length of 115 mm are produced, they are used in the installation of sewage drains in sinks, bathtubs and showers. Tees with a cross-sectional area of 110 mm and a length of 185 mm are used for bathrooms.

Installation features

The element thickness must be at least 2 mm. If the revision is installed in a channel or box, a hatch is made opposite the tee for free access. On the external sewer network, inspection wells are arranged above the hatches. According to the rules of SNiP, the distance between them should be 10 m, and at an elevation - from 3 to 5 m. The vertical installation of revisions is used on risers inside the house.

Installation is carried out according to the algorithm:

- The presence of a rubber gasket at the joint is checked.

- The ends of the elements are cleaned of dirt.

- The smooth end is inserted into the socket to a depth of at least 10 mm.

- Risers are mounted at a distance of 20 mm from the wall and revisions at a height of 1 m above the floor.

- Wiring is carried out with protrusions and branch sections, a pipeline with a diameter of 50 mm is located at a distance of 45 mm from the wall, at a distance of 75 mm with a cross-section of 110 mm.

- Plumbing fixtures are being installed.

In a private house in the drainage system, an audit is needed in the sewage system at all risers, bends and external outlet in front of the well.

Exploitation

Clogs are caused by rags dropped into the toilet, cat litter boxes, sand and household waste.

To eliminate the plug, use the revision upstream of the water flow. It is opened and cleaning is started using the rotational movement of the cable. During the event, you should ensure that it passes without the formation of loops. The rags are wrapped around the device and pulled out. In case of an operational blockage, it is recommended to flush several buckets of hot water into the sewer after cleaning for testing. Water is supplied directly to the hatch of the device, as it has time to cool down on the way from the installed plumbing.

To carry out cleaning measures in an apartment building in the absence of tenants from the lower floors, revisions are mounted in the basement.

If during operation problem areas are identified in which garbage is collected, arrange a new hatch: cut the sewer pipeline above the bell, clean the cut from irregularities, remove the chamfer and install an audit in the extension. For the subsequent connection, a branch pipe is used.

In old houses, the bolts on the cast-iron hatch doors rust, so they are cut off with a grinder, after cleaning they are changed to brass ones. If there are no bolts at hand, tighten the cover with a wire. The rubber pad can be made from a car inner tube.

Sewer revisions cost

Revision 50, made of gray pipes, costs 35 rubles.

The price for a polypropylene revision for orange-colored sewer pipes with a diameter of 110 mm "Polytek" is 138 rubles. It can withstand temperatures up to 80 degrees, with a short drain (1 minute) - up to 95 degrees.It has a double-lobe connecting ring sealing connection and providing protection against leaks.

A red PVC 160 revision costs 673 rubles.