Sewerage hoses are a type of flexible pipes designed to transport wastewater (domestic, fecal, industrial, storm water) from drainage holes, drainage and fecal pumps to the corresponding types of sewer lines. Also, flexible hoses are widely used in sewage disposal equipment designed to pump out sewage pits and flooded water wells.

Manufacturing materials

Modern sewer sleeves are made from the following polymeric materials:

- polyvinyl chloride (PVC);

- stabilized polypropylene (PP);

- low pressure polyethylene (HDPE);

- synthetic rubber (rubber).

The hoses are resistant to the aggressive environment of wastewater, can be operated in a wide temperature range from -15-20 to + 50 + 60 0С, have high flexibility, are non-flammable, safe for the environment. For additional reinforcement, many of them are also reinforced with an inner cord layer, a steel spring, and a PVC spiral.

Types of sewer hoses

All waste water hoses, depending on the nature of their surface and scope of application, are divided into 3 large types:

- Corrugated pipes for external sewerage - flexible hoses with a ribbed outer surface, designed for laying the yard sewer network of private cottages or apartment buildings and connecting them to a sewer. Such pipes are made of low-pressure polyethylene, polyvinyl chloride, resistant to negative temperatures and heavy loads. The inner diameter of the communications ranges from 110 to 1000 mm.

- Corrugated pipes for indoor sewerage - corrugations with an inner diameter of 25-30 to 110 mm, used for laying indoor sewerage and for connecting to it the siphons of sinks, bathtubs, shower trays, toilet bowl drain. Also, with the help of them, household appliances are connected to the sewer: a washing machine and a dishwasher.

- Smooth rubber hoses, PVC - hoses with internal nominal bore from 30 to 40-50 mm are used for drainage, fecal pumps, mobile sewage tank trucks. They are widely used as main pipelines in drip irrigation systems, in special devices for cleaning and washing sewer pipes from grease and other deposits.

It was decided to corrugate sewer pipes to increase their strength and reliability, the possibility of laying under highways, railways, and airport runways.

Selection recommendations

When choosing hoses for sewage, they rely on the purpose and volume of the drain.

When laying external (yard) sewer networks, special corrugated pipes made of HDPE are used; for internal sewerage, PVC hoses that are less resistant to environmental conditions are used. For drainage and sewage pumps, the most flexible and inexpensive rubber hoses are used.

For the laying of sewer lines that collect wastewater from a large number of apartments and houses, flexible corrugated hoses with a nominal inner diameter of at least 110 mm are used. When connecting individual household appliances, organizing the drainage of water points (sinks, bathtubs, shower trays, etc.), PVC hoses with an inner diameter of up to 50 mm are used.

Installation rules

- Corrugation made of polyvinyl chloride for a siphon - one end is screwed to the siphon of the drain with a nut and a tapered rubber gasket, and the other is inserted into the transition rubber cuff pre-installed in the socket of the sewer pipe.

- A corrugated hose used for draining water from a washing machine or dishwasher is connected to the standard flexible sewer outlet of a household appliance using a double-sided transitional internal nipple ("ruff") and two worm clamps. The other end is inserted into a transitional rubber sleeve in the socket of the domestic sewer pipe.

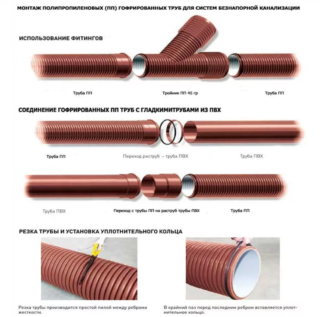

- Corrugated pipes of the external sewage system - for laying, they dig a trench with a slope of 1 cm by 1 m.At the bottom of the ditch, make a cushion of sand, sand and gravel mixture, fine gravel 20-25 cm thick.Pipes with an inner diameter of up to 300 mm are interconnected with the help of sealing gum and socket: for this, a sealing gum is put on a 2-3 groove between the ribs of one pipe, lubricate it and the inner surface of the socket on the second pipe with special grease. After that, manually or using a hand press, the pipe with a sealing rubber band is tightly driven into the second socket. Pipes with a diameter of more than 300 mm are connected using special thermal welding: an annular heating element is put on the place where two pipes join, the temperature of which contributes to the fusion and sealing of the seam.

- Smooth hoses - connected to the water pumping out pipes of fecal or drainage pumps using worm clamps.

- The corrugated rubber sleeve of sewage tanks for pumping sewage pits and wells is connected to the car pump using special clamps.

Each of these connections, if performed correctly, provides a hermetically sealed drainage system into the yard sewer network, a common collector.