The basis of the sewer system is a high-quality pipe. The higher the load on it, the stronger it should be. A good drainage pipe in the ground serves for more than 25 years without the risk of clogging, breakage, depressurization of the collector. At the same time, temperature indicators do not significantly affect it.

How to choose a pipe for underground sewage

- The amount of wastewater that will flow through the collector. The larger it is, the larger the cross-section of the external system will be.

- The level of static and dynamic load on the ground. They mean the intensity of movement on the site and the pressure of the soil on the collector.

It is good to use a pipe with the smoothest inner surface for underground sewage. This will avoid silting up the system and blocking it.

Manufacturing material and technical characteristics

For the production of external sewage pipes, four types of materials are used - polymer, cast iron, ceramics and asbestos cement. Each of them has specific technical characteristics and is good when used in certain conditions.

Ceramics

Ceramic "sleeves" have the following positive characteristics:

- high resistance to medium and higher loads;

- high throughput with an increase in diameter (up to 600 mm);

- the possibility of mounting along the joint / groove system without the use of additional couplings;

- inertness to aggressive waste media.

Ceramic pipes have two significant drawbacks - a large weight, which is inconvenient for self-laying of the collector, and the relative fragility of the material. In case of careless installation, the wall can split. More often, such elements are used for public sewage systems.

Polymer (PPP and HDPE)

Polypropylene (PPP) and low pressure polyethylene (HDPE) are used as polymeric materials. In the first case, the positive characteristics of the pipes are as follows:

- high plasticity, which reduces the risk of damage to the system during installation;

- good linear stretch ability;

- resistance to temperature extremes;

- long service life;

- low weight of elements and ease of their laying.

However, polypropylene "sleeves" are unsuitable for the construction of a city collector, since according to the maximum section of the sleeve, the system is able to withstand only average volumes of wastewater.

HDPE pipes differ in the following characteristics:

- resistance to temperature changes in the range from -50 to +130 degrees;

- the rigidity of the elements due to the corrugated outer structure (the rings play the role of stiffeners);

- resistance to mechanical stress;

- tensile strength;

- smoothness of the inner walls;

- little weight;

- long service life.

As well as PPP pipes, HDPE elements are not suitable for sewerage systems with a large volume of drains. In addition, the direct effect of ultraviolet radiation on the polymer destroys it over time. But this does not apply to the external sewage system.

Asbestos cement

Such a sewer pipe can be laid in the ground with any volume of drains. It is important to choose the right collector cross-section. Asbestos-cement elements have the following advantages:

- resistance to aggressive environments and to dynamic / static loads;

- inertness to aggressive components in effluents;

- smoothness of the inner walls;

- less than that of cast iron or ceramic "sleeves", weight.

In laying the sewage system, the mass of an asbestos-cement pipe is often its disadvantage, since one cannot cope with such work alone. In addition, the brittleness of the material with a point strong mechanical impact on it leads to a split.

Cast iron

The main positive points of a cast iron pipe are:

- resistance to various types of loads;

- inertness to low / high temperatures;

- corrosion resistance;

- service life (up to 80 years).

But cast iron also has disadvantages:

- tendency to siltation due to the imperfectly smooth surface of the inner walls;

- weight that makes installation difficult;

- the cost of the items.

It is strictly forbidden to use cast iron pipes in saline soils. Aggressive environment will corrode metal.

Sewer pipe diameter

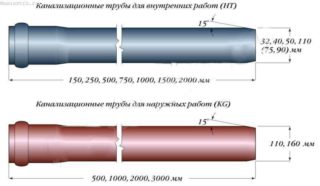

- Polymers. The diameter of the sewerage elements is from 40 to 200 mm. As a rule, elements with a cross section of 40, 50 and 110 mm are used inside the house. The external collector is mounted from pipes of a larger section.

- Cast iron. The inner section (DN) starts from 150 mm and reaches a maximum value of 600 mm in 50 mm increments.

- Asbestos cement. Such elements have diameters ranging from 75 mm to 600 mm.

All tubes with a diameter of 110 mm and more are intended only for the device of external sewer networks.

Basic requirements for pipes for sewage in the ground

In order for the sewer system to work without interruptions, it is important that the pipes for the external collector meet the following requirements:

- Durability and long service life. For a private sewage system, it is 30 years or more.

- Inert to aggressive / chemical environments.

- Resistant to temperature extremes.

- Maximum smoothness of the inner walls.

Provided that the system is correctly installed with a slope towards the drainage receiver, the sewage system will work properly without the need for expensive repairs. In this case, it is advisable to flush the collector under high pressure at least once every 5 years.