In the construction of autonomous sewerage - internal and external - pipes with a diameter of 110 mm and 50 mm are most often used. They can be made of any material - plastic, concrete, steel, cast iron, ceramics. Each has its own advantages and disadvantages, so it is important to find out which one is most suitable for installing a sewage system.

Scope of application of the sewer pipe with a diameter of 110 mm

Sewer plastic products with a diameter of 110 mm are produced in two colors. Gray pipes - for internal routing and common riser. Not intended for use at low temperatures. Orange sewer pipes - for the external line. They have a higher strength factor and can withstand frost. A common disadvantage for all polymer products is the impossibility of operation at ultra-low temperatures, therefore, in the conditions of the northern regions, it is necessary to strictly follow the installation rules and lay pipes below the level of soil freezing. Alternatively, choose a different material for the sewerage system.

In addition to the sewage system, a pipe with a diameter of 110 mm can be used:

- for casing a well, but it is necessary to immediately foresee which pump such a pipe is suitable for;

- for the organization of irrigation in summer cottages - a product with a diameter of 110 mm can act as a liner, from which pipes of a small section are extended for a drip system;

- in drainage systems and storm sewers;

- for the protection of electrical cables in industrial plants;

- for transportation of liquid waste, including chemically aggressive, whose temperature does not exceed 45 degrees;

- for the construction of a plumbing system, but only for cold liquids.

The strength of each material must be specified at the time of purchase, depending on the purpose of use. It may not be worth overpaying for some characteristics if the pipe section is on the surface of the ground and can be replaced at any time.

Manufacturing materials

Steel, cast iron, concrete are heavy materials for the arrangement of the sewer system. For its installation, you will need to attract construction equipment, which will entail additional costs. In addition, the inner surface is not perfectly flat, so organic matter remains on the walls and over time forms plugs that will have to be cleaned.

Plastic pipes have a smooth inner surface and do not oxidize. If the pipeline is installed according to all the rules, it will be difficult for organic substances to adhere to the walls. As a result, the line will require less maintenance and sometimes will not need to be cleaned or repaired at all.

To weigh all the pros and cons, you need to evaluate the characteristics of all available materials and choose the right one.

HDPE polyethylene

Low-pressure polyethylene is a fairly durable material, especially its newest modification PE 100. Suitable for embedding in concrete and laying in the ground, but the joints must be made using a welding machine necessary for working with PE 100, otherwise during operation they may disperse and expensive repairs will be required.

The advantage of polyethylene is that when the water inside freezes, the pipe expands, but does not burst. When thawed, it takes its normal shape.In the northern regions, products are additionally insulated with laminated basalt stone wool before laying in the ground.

The 110 mm polyethylene pipe can be used in pressure and non-pressure sewerage systems, as well as in pressurized water supply systems.

PVC-U

Unplasticized polyvinyl chloride (PVCVC) - used in pressure and non-pressure systems. The service life is about 50 years, which is comparable to the ultimate service life of steel structures. Suitable for transporting relatively hot liquids. Withstands temperatures from -50 to +78 degrees. PVC-U is considered an environmentally friendly material, as it does not emit harmful substances into the environment and into drinking water. A pipe with a diameter of 110 mm with a socket connection system is used for casing artesian wells up to 300 m deep. PVC-U does not affect the taste characteristics of water.

Unplasticized polyvinyl chloride is non-flammable and has low thermal conductivity. PVC-U pipes for outdoor sewerage are one of the most correct solutions in terms of price and quality.

Ceramics

The raw material for the production of ceramic water and sewer pipes is environmentally friendly - it is clay. Under the influence of high temperatures, the products are strong and durable. They are not expensive in production, therefore ceramic pipes 110 mm successfully compete with plastic ones.

The material does not react to sudden temperature fluctuations, it tolerates heat and severe frosts well. To prevent the water inside from freezing, it is necessary to additionally insulate the street section of the highway. Ceramics are not subject to corrosion, and pipes with a diameter of 110 mm are glazed on the inside for additional protection against aggressive chemicals and organics.

Polypropylene

Pipes of 110 mm made of polypropylene of type 3 have increased strength characteristics and are resistant to heat - they can withstand temperatures up to 110 degrees for a short time. They are chemically inert to acids and alkalis, therefore they are well suited for the arrangement of sewage systems. The material tolerates low temperatures worse - at most minus 10 degrees, therefore, polypropylene is insulated for laying in the ground.

Steel

Steel wiring is most often done for urban sewage, since the material has increased strength characteristics and can be used in conditions of vibration and ground movement - under highways. For home systems, such a material is rarely used due to the large weight of steel products. To install them, you need to use special equipment.

Steel is not resistant to corrosion, in addition, organic waste and mineral deposits remain on the pipe walls and reduce the throughput. Anti-corrosion coatings do not give a complete guarantee of high-quality work, as they wear off over time. Steel pipes 110 mm are gradually being replaced by plastic ones, since they have approximately the same service life.

Polyvinyl chloride

PVC pipes 110 mm are designed for operation in a limited temperature regime - from 0 to 45 degrees, which does not always suit consumers. They are mainly used to transport cold tap water. In addition, for the winter period, they must be insulated without fail.

PVC pipes are produced with a limited diameter from 110 to 200 mm, so they are suitable for home construction, but larger sizes are required for capital construction.

Non-pressure PVC sewer pipes must be laid in the ground in compliance with all the rules for connecting the end parts and the slope of the line.

Concrete

Reinforced concrete pipes can be laid to a great depth - up to 6 meters. They withstand the pressure in the system, therefore they are used in pressure sewer mains - private or city.

The service life of reinforced concrete is more than 80 years with proper operation and timely maintenance.Concrete is resistant to corrosion, but unsafe from the point of view of bacterial contamination, therefore, this material is not suitable for supplying drinking water to a house.

Cast iron

If earlier it was thought that cast iron is a bad solution for private sewage due to its rough inner surface, now there are metal grades that can compete with plastic in terms of the smoothness of the inner walls. At the same time, cast iron is a very heavy material, so it is rarely used in home construction, especially with a limited budget.

Coating with anticorrosive mastics extends the service life of the products and makes it an almost eternal material that does not require replacement and maintenance.

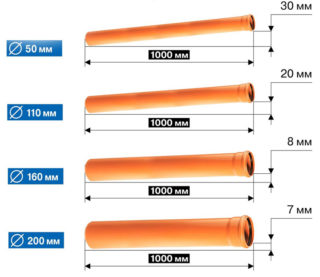

Dimensions (edit)

Red sewer pipes with a diameter of 110 mm can have different wall thicknesses - from 5 to 150 mm. It depends on the inner diameter and the place of installation - in a pressure or non-pressure line. In systems where fluid is transported under pressure, the walls must be thicker to withstand constant loads and not deform.

The length of a pipe segment for each material is determined by GOST standards. Some plastic products can be transported in coils for the convenience of customers. The required length is measured and twisted, then fixed.

Criterias of choice

In order to choose the right material for arranging the sewage system, the following parameters must be taken into account:

- the temperature regime of the region - the stronger the frosts, the more resistant the material should be;

- the depth of laying in the ground and the degree of soil mobility, as well as the presence of vibrations;

- pressure or gravity sewage - for pressure, material with thicker walls is needed;

- internal or external system;

- do you need sound insulation - cast iron reduces sound waves well, plastic does not remove them.

One of the selection criteria is the price, but it is not recommended to save on installation or connecting elements. Poor quality parts can shorten life or lead to repair costs.

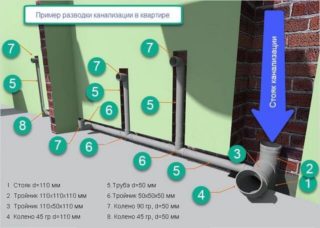

Installation features

Plastic pipes are mounted using several methods - welding using special equipment, fittings. Most polymers when welded create strong joint seams that do not break over time. Press fittings are more reliable in the installation of joints and are recommended for closed use - in concrete, in the wall, in the floor. Compression fittings are made when the seam is accessible and can be repaired at any time.

Steel pipes are connected only by welding, especially with a large burial depth.

Cast iron and ceramic pipes have a special connection device - a socket. Various mastics are used for sealing, so that liquid does not seep through the joint.

The pressure sewage system is allowed to be installed horizontally, since the drains will be transported using a pump that increases the pressure. For free-flow sewerage, the slope must be observed. For a 110 mm pipe, it is 2 cm per linear meter. This is necessary so that the highway does not get silted up and the throughput does not decrease.

The cost of pipes depends primarily on the amount of consumable material and its composition. For the production of plastic, the cheapest raw materials are used, so the final price for plastic sewer pipes with a diameter of 110 mm will be lower than for steel or cast iron products. In this case, the thickness of the walls and the length of the segment are important. New material modifications can cost more, but before paying, you need to figure out how useful the stats will be.