Two-layer elements of the Pragma sewer pipeline are made of the latest generation of polypropylene. They are produced by the Pipe Life brand from Austria. According to European standards, the corrugated outer surface of the pipes is red, and the inner one is smooth grayish-white, which is convenient for teleinspection. Technical characteristics fully comply with Russian GOST standards.

Scope of use of pipes "Pragma"

Scope of elements:

- household needs;

- diversion of surface water flows;

- removal of industrial effluents;

- soil drainage;

- arrangement of agricultural cleaning networks.

With their help, sewage channels are organized in road embankments, port terminals and airports. Most often, the elements are used in the construction of a gravity sewer network or storm drain, as well as drainage systems.

Specifications

There are two main types of tubular elements: Pragma with a ring stiffness index of 8 kN / m2 and Pragma PRO16 - 16 kN / m2.

The main design characteristics are:

- creep coefficient - less than 4;

- ring flexibility - more than 30 percent;

- maximum laying depth - up to 10 m;

- tightness guarantee - up to 0.5 bar.

Sizes of pipelines for sewerage "Pragma" are calculated by the external section - from 160 to 1140 mm. The length of the pipes is 6 or 12 m. The latter option is more economical in terms of cost and time spent on installation.

Advantages and disadvantages

The Pragma polypropylene sewer system has the following advantages:

- no deposits on the walls and high permeability due to the extremely smooth surface inside;

- the possibility of teleinspection;

- immunity to decay and mold;

- light weight;

- ease of cutting during installation - you can use an ordinary saw;

- resistance to ultraviolet light and aggressive media;

- dielectric qualities;

- resistance to high and low temperatures.

The pipeline is able to withstand long-term operation at 60 degrees of heat and short-term discharge of hot water up to 95 degrees. The pipes are designed for 100 freeze and thaw cycles without loss of technical performance. They can be mounted in frost up to 25 degrees.

The disadvantage of polymer pipes is their sensitivity to strong mechanical stress, which can cause cracks and dents. In corrugated pipes "Pragma" this minus is leveled due to the additional rigidity arising from the corrugated surface. This makes it possible to carry significant earth loads and lay the pipeline even in dense soil conditions and under highways.

The only drawback of Pragma products is the rather high price.

Installation features

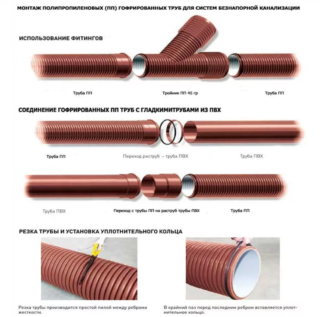

The connection is carried out in three stages:

- Cleansing the jointed areas from dirt and foreign objects. The seal should already be in place.

- Silicone lubrication of the seal and flare part from the inside.

- Connection of two sections until it stops.

For a stronger joint, use a lever or an excavator bucket. To protect the pipe from damage, a wooden cross-bar gasket is used.

The second way to assemble the pipeline is using couplings. It is suitable for short branches and is carried out as follows:

- The pipe is cut to the required size (in the intercostal cavity).

- They clean and trim the saw cut.

- Connect two parts with a fitting in the same way as in the first case of the assembly.

If no silicone based lubricant is available, use a highly concentrated soap solution. The use of lubricants containing oils and fats is not recommended. Such compounds reduce the quality of the O-ring, and, as a result, the tightness of the connection.

If the installation is carried out at a temperature below zero, glycerin or alcohol is added to the composition. Before joining in the cold, the sealant is heated in hot water (about 80 degrees).

Pragma pipe sections can be connected to cast iron, steel or PVC sewerage elements. The joint is created using transition fittings for soft materials.