Sewer pipes made of unplasticized polyvinyl chloride, created using the latest technologies, have high technical characteristics, which affects the durability of underground communications. High-quality PVC-U plastic has become the main raw material for the production of tubular elements and fittings, as they work best in specific operating conditions, where the use of soft plastics is limited.

Characteristics of PVC-U pipes

Raw materials were obtained in Germany to replace rolled metal products. Solid polyvinyl chloride works effectively and for a long time under certain conditions. The new material elements have a long service life and are chemically inert. Their price is optimally matched to the characteristics of the plastic.

PVC plastic is used for the manufacture of handles, cards, cable windings. It is obtained from secondary raw materials (up to 40%), oil products and table salt. PVCVC contains unmodified edible resins in primary processing so that the material does not lose its physical and mechanical properties: strength, hardness and ductility, otherwise the pipes will break, crumble and bend, which will not allow them to be used, for example, for casing wells. Plasticizers are removed from the composition of the components, which gives the elements the necessary rigidity, strength and excludes chemical reactions in contact with liquids.

Solid polyvinyl chloride has a special cross-like structure of molecules, which is obtained after heating and subsequent cooling.

The unique properties of the material make it possible to manufacture pipes for a wide range of uses, which determines their size, thickness and stiffness class.

Appointment

They are used for sewer distribution inside the building and external networks, as well as for pressure sewerage. For each type, products with special characteristics are intended, therefore, their interchange is not recommended, since the use of parts with high strength inside the house unreasonably increases the cost of the project. The use of lightweight thin-walled pipes for an external network will not ensure its reliability and durability.

From PVC-U pressure sewer pipes, sewer sections are mounted after fecal pumps. They have no sockets, so the joints are welded. Products withstand not only high external pressure from the ground, but also internal pressure generated by a hydraulic machine.

The size

For economical use, the manufacturer produces elements of different lengths. Indoors, it is most convenient to install wiring from sections ranging from 30 cm to 2 m, for external networks from 50 cm to 6 m. The proposed range allows you to reduce the number of connections and increase their tightness.

The marking of plastic pipes, in contrast to rolled metal products, is carried out according to the outer diameter.

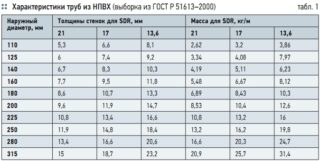

Wall thickness

Difficult operating conditions require varying degrees of strength. Depending on demand, PVC parts are produced from one or three layers.The latter modification has high wear resistance, since PVC-U is used for the outer layers, and foamed polyvinyl chloride is used as the inner layer, which is resistant to temperature extremes, chemical and mechanical influences, is durable and can withstand different processing methods.

For wiring inside the building, thin-walled sewer pipes with a thickness of no more than 3.5 mm are used. They do not experience pressure from the ground, like external sewage pipelines, the thickness of which can vary from 3.5 mm to 15 mm. The use of three-layer PVC-U pipes increases thermal insulation and strength, and reduces the weight of the structure.

Stiffness class

Products with characteristic N, normal stiffness SN4, are laid in the ground to a depth of 6 m, they can withstand small dynamic loads from rarely passing vehicles.

The SN8 strength class shows a high ring stiffness, thick-walled pipes can be laid 80 cm from the ground surface or to a depth of over 6 m, and they are laid at a level of 8 m under highways.

Selection recommendations

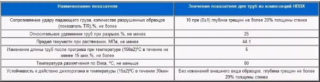

For internal and external sewerage, products are used that meet the following requirements:

- temperature range from 0 degrees to 45 degrees;

- the ability to withstand the pressure of the environment from the inside, which is created by a pump for moving liquids and gases;

- resistance to many types of chemical and organic compounds: oil, milk, mercury, acids.

The smooth inner surface of the PVC-U material reduces the likelihood of debris blockages. The products are aesthetic and safe. For wiring inside buildings, pipes are used in gray, for outdoor installation - red.

Installation features

Installation with sockets is considered the easiest. To eliminate leaks, rubber gaskets are used. Cold welding is used for pressure pipes, it is performed using chemical compositions. Adapter couplings reliably connect products made from dissimilar raw materials.

Advantages and disadvantages of PVC-U pipes

Increasingly, users prefer modern materials with undeniable advantages over cast iron and ceramic elements:

- Lightweight, do not create problems during transportation or installation.

- Do not rust.

- Resistant to abrasion and chemicals, which allows the use of products for wastewater with mechanical contamination.

- Amenable to any processing and easy to cut.

- They have a long service life with proper operation (50 years).

Minuses:

- Restrictions on the temperature range, from -5 to 40 degrees, withstand +60 degrees for a short time.

- Not protected from rodents.

- Low fire resistance, when burning, they emit toxic substances.

Low frost resistance makes the products fragile. To prevent freezing of the pipeline, it is packed in heat-insulating materials.