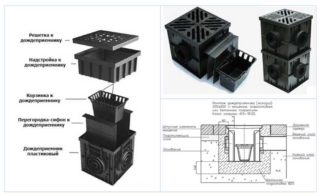

The device of a point (closed) storm drain requires a special reservoir in its design - a storm water inlet. It is designed for the initial accumulation of rain / melt water and its further transportation to the point of discharge through pipes deepened into the ground. Competent installation of a storm water inlet with your own hands ensures the operability of the drainage system without failures and breakdowns.

Types and arrangement of storm water inlets for storm sewers

- Removing liquid down. Such elements of the storm drain direct water into the ground, directly into the drainage well.

- Removal of drains to the side. Such a tank is connected to the pipes into a single structure.

All storm water inlets differ in size, permissible loads, type of material and shape. Stormwater tanks are labeled depending on their purpose:

- E. Marking means “storm water inlet”. The element is used in private areas and in the pedestrian zone.

- DB1 and DB2. It is interpreted as a "big storm water inlet". Installed in car parks and along city carriageways.

- DM1 and DM2. Main storm water inlet.

- DS1 and DS2. Super heavy storm water inlet. Designed for installation in areas with maximum load.

- DC. The storm water inlet is round.

Element material for point rainwater collection: cast iron, plastic and concrete.

Cast iron storm water inlets

Cast iron stormwater elements are the most durable and at the same time heavy. Metal grade SCh20 perfectly withstands loads from 15 to 25 tons (depending on the dimensions of the tank), is inert to aggressive media, durable and corrosion-resistant. More often, cast-iron storm water inlets are used in the construction of urban sewer mains. The tanks have a high flow rate and, at the same time, are environmentally friendly. The metal does not pose a threat to the environment.

Installation of a storm water inlet in the blind area of a house, provided that it is of a cast-iron structure, must be accompanied by a special concrete base. Otherwise, the metal will start to rust. In addition, it is difficult to work with cast iron elements due to their heavy weight.

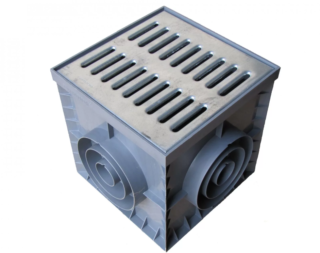

Plastic

Polymer tanks are widely used in private and municipal construction. Plastic has the following advantages:

- light weight;

- high resistance to temperature extremes;

- inertness to chemical / aggressive media;

- ease of installation and maintenance;

- a wide range of models in size and shape;

- favorable cost of products.

It is easy to take care of polymer reservoirs for rain runoff: dirt, silt, sand are easily washed off with a stream of water.

All plastic models are labeled according to their rated load:

- A. The load is up to 1,500 kg. This option is good for private construction.

- B. The rainwater inlet can handle loads up to 12.5 tons.

- C. Maximum load capacity up to 25 tons.

- D. Load up to 40 tons.

- E. Nominally withstands up to 60 tons.

- F. Capable of supporting up to 90 tonnes.

It is better to buy a storm water inlet, which is able to withstand a slightly higher load than was obtained in the calculations.

Concrete

Such a storm water inlet has slightly less weight than a cast iron one. The material is characterized by resistance to aggressive drains, durability and good flow capacity. But the inner surface of concrete tanks is slightly rough, which provokes the build-up of silt on its walls over time. The accumulated sludge will give off an unpleasant odor as the moisture in the tank evaporates. In addition, concrete is a massive material that requires the use of special equipment when laying.

Massive rough concrete can be replaced with lighter and smoother polymer concrete. Polymers added as reinforcing fibers make the final product lightweight, durable, and prone to high stress.

Criterias of choice

The choice of the type and model of the storm water inlet is influenced by the following factors:

- The total area of the territory from which rainwater will be removed. Through it, the volume of runoff in the rainy and snowy seasons is determined.

- Coefficient of water absorption of the existing coating. For asphalt it is 0.89, for the roof - 1, for crushed stone - 0.4.

- Weight and type of material. It should be borne in mind that cast iron elements are prohibited for use in saline soils, otherwise the salt will spoil the metal over time. Most often, in private construction, plastic storm water inlets are used.

- The level of the nominal load on the tank.

- Cost and dimensions.

- The presence of additional elements: locking mechanism, gaskets, etc.

If none of the reservoir options is suitable for the price and there is an extra brick on the site, you can lay out a storm water inlet well from it. It is important to correctly calculate the required volume and then plaster / paint the tank from the inside.

Installation features

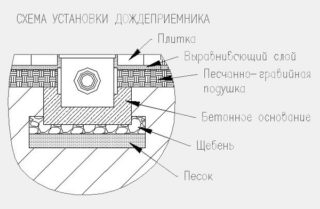

- Preparation of the pit. Its depth should be equal to the height of the tank with the grate plus 30 cm for the filling of sand and concrete. On the walls, the dimensions of the pit are increased by 15-20 cm on each side for concrete pouring.

- A layer of sand 15 cm thick is poured at the bottom of the pit and rammed well.

- A concrete solution of cement and crushed stone is poured on top. The mass is allowed to dry for the installation of the tank. Such a site will serve as a solid foundation. During the pouring of concrete, evenness is monitored using a building level.

- On the frozen solution, a stormwater inlet is installed at the level, having previously freed the pipe from the gasket. A branch of the stormwater is inserted into the tank and all joints are coated with a sealant.

- The storm water inlet is poured from all sides with concrete mortar to the uppermost edge. During pouring, you need to carefully expel air from the solution with a metal rod, otherwise the walls of the reinforcement will be porous and fragile. Subsequently, they can succumb to the effects of heaving soil.

- Once the mortar has set well, the basket and the upper protective grill can be installed.

When installing a storm water inlet in the blind area, it is better to do all the work at the stage of its filling, so as not to break the already frozen area around the house in the future.

When installing a rainwater collection tank, it is worth considering the ability of the soil to shrink, expand and swell with temperature changes. Therefore, it is not worth saving on concrete pouring of the storm water inlet. Otherwise, over time, it can float up like a float. The soil will simply push it out.