For summer cottages, the problems of soil oversaturated with moisture are relevant. This negatively affects the yield of crops. But no less important is the need to protect the foundations of buildings and structures from the action of groundwater. If you properly drain the area and install the plastic drainage well, you can easily solve the problem of excess moisture in the area.

Types and arrangement of drainage wells

- Drainage tanks - collect water from the entire drainage system. Installation is carried out at the very bottom of the site. Sealed containers are often equipped with pumps. Water from the drainage tank is subsequently diverted to the general sewer, or used for irrigation on the site.

- Inspection or inspection shafts - these structures are equipped with a hermetically welded bottom. They are used to monitor the operation of the drainage system and periodically clean it from silt and debris. The distance between observation shafts should be no more than 50 meters on straight sections. In addition, they are installed at pipe bends. Inspection wells are often made of drainage pipes.

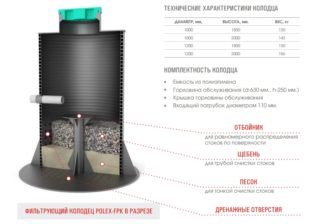

- Containers without a bottom are used as filter elements.

- Expansion tanks are installed to reduce the pressure in the drainage system. It is used in regions with abundant rainfall.

- If the suburban area has a complex relief with large elevation differences, it is rational to additionally install drop wells.

- bottom;

- mine;

- neck;

- Luke.

The outer surface of the container is made in a smooth or corrugated form. Corrugated models are highly durable and reliable. The ring stiffness of the header allows it to withstand the heavy loads generated by the soil.

Manufacturing material

Concrete structures are a traditional option for drainage wells. They are arranged independently, or from ready-made reinforced concrete parts. The main advantage should be called the possibility of descent into the tank and the implementation of cleaning. But serious disadvantages are the large weight of individual elements, as well as the complexity of transportation and installation.

Plastic models are becoming more and more common, especially for the device of suburban systems. They have a lot of advantages over other materials:

- Simple in design and easy to install.

- They are provided with openings for supplying pipes, which are equipped with rubber cuffs. This greatly increases the tightness of the structure.

- Lightweight and inexpensive.

- Transportation and installation of a plastic drainage well is not difficult. It does not require the use of construction equipment.

- The material is resistant to chemicals.

- Manufacturers produce a wide range of multifunctional components.

- The service life is long enough.

Plastic products are made from polyethylene (HDPE), polyvinyl chloride (PVC), polypropylene (PP). For their manufacture, smooth or corrugated plastic pipes with a diameter of 300 mm or more are often used.

The simplest structures represent a common pit, into which water enters. However, the walls of a homemade well should be concreted. So it will last longer and more reliably.

The main criteria for choosing a drainage well

For manholes, pipes with a diameter of 300 mm or 400 mm are usually used, drainage products are taken of a larger size. The height of the shaft is determined based on the depth of the drainage system. It is measured from the lowest point of the outlet pipe. For arrangement in the lower part of the structure of the settling chamber, it is required to add 20-40 cm to the length of the shaft.

For drainage wells that are planned to be equipped with a pump, the diameter of the shaft must be at least 50 cm.To install it, it is worthwhile to provide for a chamber device with a height of 50 cm to 100 cm.

For ease of operation and maintenance, additional plastic components are produced:

- bottoms;

- hatches;

- couplings for connecting pipes;

- check valves.

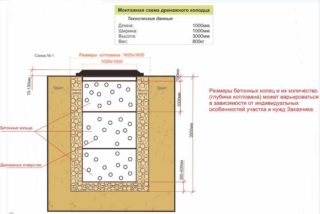

Reinforced concrete rings for drainage wells are selected from moisture-resistant concrete grades. The size of the elements depends on the purpose of the tank. They are produced with a diameter of 70-200 cm and a height of 10-100 cm. For summer cottages, a circumference of 70-150 cm is suitable.The width of the ring is selected from 50 cm to 60 cm.

Preparatory work

Preparatory work before the installation of a drainage well on the site consists of digging trenches and assembling a structure from pipes.

When arranging the system, first of all, it is worth deciding on the places of installation of the drainage structures. The installation technology depends on the type of tank. For rotary, inspection and drainage structures, concreting of the site is preliminarily performed. For filter tanks, a base is prepared from a layer of sand and crushed stone. It is advisable to lay a layer of geotextile under the structure.

Installation steps

- The pipe is cut to a predetermined length - the height of the shaft.

- The bottom is attached to the bottom.

- Holes are cut in the walls of the shaft for the entrance of the drainage pipes.

- The connection of pipes and containers is performed using couplings.

- If required, a check valve is installed at the end of the inlet pipe.

Inspection shafts are installed in a drainage ditch, assembled and covered with a layer of rubble.

The assembly and installation of the storage tank is performed in a similar way. They can be carried out vertically and horizontally. In addition, the arrangement of a drainage well may include the installation of a pump and the connection of pipes that drain water into the general sewage system.

The final stage of installing a plastic drainage well will be the laying of the hatch.

Installation of a water collector made of concrete rings

Concrete structures are installed at a depth of more than 200 cm. Installation is carried out in two ways. In the first version, soil is gradually removed from under the laid ring. Under its own weight, the element is lowered to the required depth. In the second case, the rings are installed in a previously dug pit.

- Trenches for pipes are dug from the reservoir.

- Holes are punched in the concrete walls.

- Rubber seals are put on the ends of the pipes.

- The pipes are fixed in the holes and sealed.

At the end, the structure is sprinkled with gravel. A hatch or ceiling is laid on top.

The cost of installing a drainage well depends on the material, the size of the tank, the design of the tank, and the manufacturer. Correctly selected option and competent arrangement of the system will guarantee long-term operation. Compliance with the installation technology will avoid many problems in the maintenance of the system.