Stainless steel drainage channels are an important element of the overall sewer design. They are used to collect used water and then discharge it into the sewer pipeline.

Scope of products

Stainless steel tray products are used both indoors and in open areas. In the first case, they are used for industrial needs:

- at catering establishments;

- in retail outlets;

- in the manufacture of medicines, perfumes and cosmetics;

- in medical institutions and laboratories;

- in swimming pools, bath and laundry plants, saunas;

- in the refining industry.

Open use of trays is possible for draining water from garden paths, balcony and terrace structures, glazed facades, staircases. The devices are used to create winter gardens and roof landscaping.

Specifications

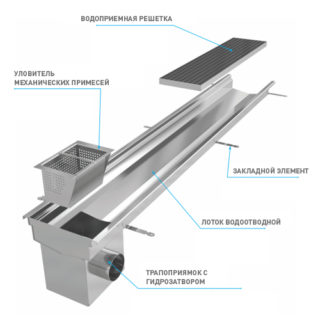

Drainage structures outwardly resemble gutters, the bottom of which is made in such a way that its halves converge in the center at an angle. This makes the trays less clogged. The body is usually rounded in order to limit the deposition of dirt and facilitate easy cleaning.

Dimensional indicators of devices:

- The initial depth varies from 60 to 90 mm, the final depth - from 100 to 300 mm.

- Width from 100 to 400 mm.

- Standard section lengths are from 1000 to 9000 mm.

Manufacturers offer designs with two cross-sectional options along the section length: simple and variable. The latter option is suitable for those cases where it is not possible to bring the required slope along the floor level. The creation of the correct angle at the bottom of the trough ensures the necessary rigidity of the entire structure and effective drainage.

Products are made of stainless steel alloys with a thickness of one and a half to three millimeters.

The parts of the trays are connected by welding or using flanges at the ends of the sections. The tray sections are assembled with stainless bolts through a gasket.

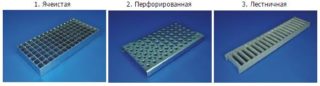

To prevent various debris from entering the drain, the products are equipped with steel gratings. Water passes through them, and large debris fractions remain on the surface. There are also slotted variants, when the upper surface with longitudinal holes is already attached to the body.

Installation features

Steel gutter installation:

- The tray fits into its intended place and is horizontally aligned by adjusting the feet in height. The top of the gutter should be one centimeter below floor level.

- The metal channel is rigidly fixed to prevent its displacement during the pouring of the concrete solution. For this purpose, the legs are bolted to the floor or welded to the reinforcement.

- Transverse partitions are inserted into the places where the gratings are installed in order to avoid compression of the tray in width during the concreting process.

- All removable parts of the gutter are removed: grids, waste bins, siphons.

- The concrete mortar is poured to the level of the fasteners.

- When the concrete has set slightly, the structure is checked for distortion.

- The concrete mixture is poured to the edges of the structure.

In hard-to-reach places, the solution is applied with a spatula.

Steel trays are attached to the drains that connect them to the sewerage system.These parts can also be used independently if they are placed in points of a point catchment.

Ladder parts are small tanks. They are equipped with horizontal and vertical outlets for connection to a downpipe. Due to the difference in connection methods, they are easy to install where the sewer network has already been equipped.

Advantages and disadvantages

Stainless steel products, be they beams, ladders, trays, have the main advantage: they are not afraid of corrosion and are resistant to aggressive external influences, both chemical and temperature.

Other advantages of tray devices include:

- increased bandwidth;

- strength and durability;

- variety of configurations;

- aesthetically pleasing appearance;

- compatibility with any floor coverings;

- ease of maintenance and control of functioning;

- the ability to self-purify;

- environmental safety.

The disadvantages of such structures include their rather high cost. Extremely high loads, which are on busy highways, they will not withstand.

Steel tray products comply with all sanitary and hygienic standards. You cannot do without them in enterprises where these requirements are especially stringent.