If a new or renovated house is left without a drain, sooner or later the walls, foundation, and attic will lose their appearance. Perhaps mold will start in the attic and additional financial investments will be required. Repair or construction can be considered completed when the gutter system is installed and functioning.

Purpose of drainpipes

In winter, ice forms on the roof slopes, which can fall down during a thaw and injure people. Additional insulation of gutters with an electric cable reduces the risk of icicles falling, as the melt water flows down the drain.

If the walls are insulated with mineral wool or other energy-saving materials, the ingress of water can cause them to deteriorate, as a result of which they will no longer be able to perform their functions. Damage to finishing materials is possible: stains, chips and damage to the color of the paint, no matter how resistant it is. Facade tiles can collapse due to water ingress between the seams.

Classification by section shape and other parameters

Downpipes are distinguished by the following parameters:

- production material - galvanized steel, copper, plastic, metal-plastic, aluminum, wood;

- shape - round, square.

All elements of the drainage system are made of the same material so that there are no deformations due to a different index of thermal expansion. Materials can be selected at an affordable price. It is important to foresee the average amount of precipitation in the region, as the size of the gutters will depend on this.

Plastic gutters

Plastic in drainage systems is often used because of its low cost. At the same time, it is possible to choose the color and shape of the gutters and other structural elements. Plastic pipes do not rust or change color over time.

Due to their light weight, they are easier to install and do not place stress on the building façade. Special attachments for coupling parts facilitate assembly of the system.

Besides the advantages, there are also disadvantages:

- unprotected plastic quickly loses its characteristics under the influence of ultraviolet radiation;

- improperly selected materials in homemade structures can crack in the cold, since not all types of plastic are resistant to low temperatures;

- deformations occur with sudden changes in temperature.

Polymers can break under mechanical stress - falling branches or stones.

Cink Steel

Galvanized steel downpipes are installed in the private sector and industrial enterprises. Such systems are inexpensive, but they have drawbacks. First of all, they are susceptible to corrosion, so a long service life cannot be expected. The zinc coating wears off over time due to debris, hail, ice. Unprotected steel begins to oxidize, and the gutter flows through the holes formed.

Aluminum

Aluminum is one of the lightest metals used in the construction of drainage systems. It does not rust due to the oxide film formed on the surface. Aluminum gutters are sometimes coated with a water-repellent material to reduce the damaging effects of moisture. On sale you can find galvanized aluminum with a water-repellent coating. Such products serve for a long time and do not lose their attractive appearance.

Wood

Wooden gutters are installed on timber houses so as not to spoil the overall impression of the style. At the same time, they choose a hard tree and treat it with various chemicals from mold and insects. Over time, wooden drains lose their appearance and require restoration or replacement.

Copper

Copper gutter systems are the most expensive solution for a private house, but they serve for a long time. Over time, copper becomes covered with an oxide film and changes color. Sometimes, when ordering, the material is artificially aged to obtain the desired shade - patina.

Copper does not rust, does not create much noise when water passes through the gutter structure, ultraviolet radiation does not have any negative effect. In theory, the material can be used for up to 300 years. In order for the products to withstand the specified period, plasma welding is used, sheet copper of a certain thickness and quality is used.

Combined systems

Metal-plastic gutters are a good solution in terms of quality and price. They can withstand a long service life, as they consist of a metal sheet, sheathed with plastic on both sides. Inexpensive galvanized steel is usually used as the metal. Frost-resistant plastic with sun protection.

Reinforced-plastic structures for private houses are chosen for several reasons:

- appearance of products - you can choose any color of walls and roofs;

- plastic with metal is a more durable combination than just a polymer product;

- you can order ready-made systems according to the customer's size.

Metal-plastic drainage systems are assembled quickly and do not require experience. For installation under the roof, it will be necessary to additionally mount the fastening clamps on the walls.

Dimensions of gutters

The dimensions of the parts of the drainage system are selected based on the average annual rainfall, as well as the roof area. The depth and width of the gutter are decisive. For him, you can choose the following sizes:

- the width of the tray should be 100 mm, the diameter of the downpipe is 75 mm, if the roof area is less than 50 square meters;

- tray width 150 mm, pipe 90 mm, if the area is up to 100 sq. m;

- if the roof area is more than 150 sq. m, the tray should be up to 200 mm wide, and the pipe diameter up to 120 mm.

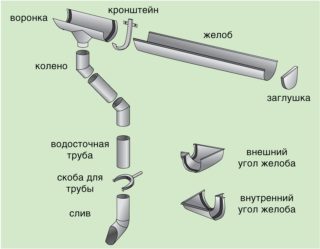

In addition to gutters and pipes, the drainage system includes funnels, brackets for attaching the gutter under the roof, clamps for attaching pipes to the wall, elbows for draining water into the storm sewer. Caps and corners are calculated depending on the roof configuration.

Calculation of the number of downspouts

To begin with, they are determined with the number of risers. In ordinary houses, there are at least 4 of them. If there are extensions, they are also taken into account. Then the distance from the roof to the ground is measured and this number is multiplied by the number of risers.

Next, the length of the gutters is calculated. To do this, measure the perimeter of the house and outbuildings. The number of funnels is determined by the number of corners, but can be set in a different way. For example, in the center of the wall and in the corners. In this case, it will be necessary to take into account the slope of the gutters so that they direct the water to the funnels. This is important in winter, as ice in the gutters can ruin the coating or lead to cracking of the material. If one side of the perimeter is too long, it makes sense to install another riser in the middle with an additional funnel.

Installation steps

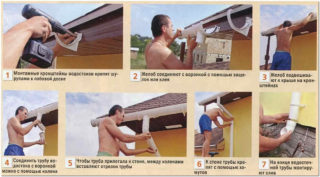

After the gutters are laid, and the edges are sanded (if the drain is done by hand), you can proceed to the installation of risers:

- The vertical pipe is inserted into the funnel.

- Clamps are attached to the wall and the pipe is compressed, but not strongly, since in the heat the materials expand and can deform the wall. The pipe must move freely inside the clamp.

- Elbows may be required to drain liquid into the storm drain.

So that the joints do not diverge, during operation it is recommended to lubricate them with a sealant and degrease them before applying it. It is better to mount the structure in the warm season. At subzero temperatures, materials behave differently, especially polymeric ones.

When installing, it is necessary to correctly calculate the number of brackets. If there are not enough of them, the structure can sag and break.

To check how the drainage system works, you need to direct a hose with water into the gutters and see if there are any leaks. In the fall, before the onset of cold weather, it is necessary to clean the gutters from leaves and falling debris so that they do not clog pipes and storm sewers.

Cost of gutters

A do-it-yourself drainage system from galvanized steel or plastic pipes will cost the least. This kind of work takes time and tools. You also need to know which polymer is most suitable for the manufacture of gutters, how it will function in winter.

The price of plastic downpipes combined with steel is slightly higher. Such structures are usually bought ready-made and quickly installed under the roof.

The most expensive gutters are copper. Here, pricing is influenced by the cost of the material itself and welding, which are performed at a plasma jet temperature of about 6000 degrees. This method allows you to get outwardly smooth joints without distortions and scale.

The more material goes into the manufacture of the entire system and additional parts, the higher the total cost of the finished structure. The price also includes fastening materials - screws, screws, nails.