On a flat roof, a reinforced drainage system is needed, because with heavy precipitation, puddles form, which gradually destroy the waterproofing layer. In the room under the roof, streaks appear on the walls. The second problem is dirt, the third is plant seeds that germinate in a humid environment and damage the coating with their roots. The way to get rid of puddles is special drain funnels.

Definition and purpose

Previously, flat roofing was an attribute of industrial buildings or multi-storey residential buildings. In the private sector, this usable area is used for arranging a terrace in the summer, a sports field and even a pool. Often it has a fence - a parapet, because of which precipitation cannot spontaneously leave the roof. For this, various methods of removing water have been invented.

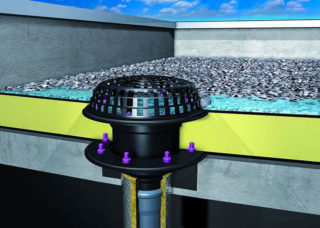

The drain funnel is designed to collect sediments and direct them into the downpipes, and then into the storm sewer. In order for the liquid to enter the sump, the roof must have a slope - absolutely flat roofs are not made, as this leads to stagnation of water.

The central structural element must be securely and hermetically installed - the durability of the roofing depends on this. If part of it is damaged, another rain will cause destruction inside the building, which will lead to costly repairs and replacement of the entire coating.

Types and arrangement of drainage funnels

- Traditional. Recesses for funnels are laid during the construction of buildings. Their total number is calculated based on the roof area - on average, one per 25 square meters. The downpipe is directly adjacent to each funnel, then the water flows into a common pipe. The method of removing precipitation - external or internal, depends on the climate. In warm regions, the outdoor type prevails, in countries with a cold climate, the indoor type, which excludes the freezing of precipitation.

- Gravitational vacuum system. The principle of operation is ejector: air masses carry water with them, and it moves downward at high speed under the influence of gravity. It is not necessary to make a slope, since the liquid flows off on its own under air pressure. For example: a vacuum system with a diameter of 75 mm is capable of passing 15 liters of water per second, while a traditional design must have pipes with a diameter of 200 mm to handle the same volume. Fewer funnels and drainpipes are required, which translates into cost.

The design of the drain funnel has the following device:

- the side for receiving water is usually wide and sloping towards the center;

- glass - necessary to collect liquid and send it down - into the pipe;

- a cap in the form of a mesh with ribs is necessary so that leaves and various debris do not fall into the sewer.

If the roof is used for pastime, choose flat funnels. Such models are relevant on roofs covered with tiles or a layer of asphalt. There are varieties of electrically heated roof outlets to prevent precipitation from freezing in the downpipe in winter. They are only metal, since not all types of plastic can withstand high temperatures and begin to melt. One-level or two-level models are used depending on the roof structure.Instead of a roofing felt apron, a crimp seam can act as an attachment - a universal device for any material and roof structure.

Additional accessories for installation are gaskets made of rubber with bitumen, which provide reliable insulation. The branch pipe can be horizontal or vertical, depending on the type of drain. Oil seals are elements that prevent water from flowing out at the junction of the pipe and funnel.

Manufacturing material

In addition to the most expensive and durable material - copper - funnels are made of cast iron, steel, plastic. There are also combined designs.

For the arrangement of a rigid roof, cast-iron gutters, steel, aluminum water intakes are used. Cast iron is a very strong and durable material. Its service life is more than 50 years. For the manufacture of roof elements, gray and alloy cast iron are used, which tolerate temperature changes well and are resistant to shock loading. For resistance to acid precipitation, the funnels are covered with a special protective paint. The disadvantages of the material are the high price and high weight.

Stainless steel can last a long time and its carbon content must be low to prevent rusting. The best option is steel interspersed with titanium, molybdenum. Such species better tolerate temperature extremes and the effects of atmospheric precipitation of various chemical compositions.

Aluminum flat roof gutter due to the oxide film practically does not interact with the environment. The metal is durable and does not corrode. Due to the plasticity of aluminum with temperature changes, it does not cause deformation of the roof. The material is lightweight, therefore it does not cause difficulties during installation, and also reduces the total weight of the roof.

Plastic funnels are used to equip gutters from flat roofs if the roof is made of soft materials. Polymers are absolutely not subject to corrosive processes, ultraviolet radiation, due to the smooth surface, they do not accumulate dirt - it is washed off in the first rain. Organic substances do not adhere to the material, and chemical components are not able to cause their destruction or deformation.

Combined funnels for drainage systems are made on the basis of plastic. This increases the service life of the structure and makes it more resistant to environmental influences and mechanical damage.

How to choose

Funnels are selected based on the following factors:

- Temperature in winter. If frosts often occur, it is better to use a cable for heating the system. In this way, ice build-up and roof collapse can be avoided. Only metal products can be heated. Cast iron and aluminum respond well to rising and falling temperatures.

- In warm climates, aluminum is also a good option if the roof is made of hard materials. Plastic or combined products will suit any type of coating.

- The funnel must have a protective grill or cap against debris, otherwise the drainage system will clog up and water will flow from the roof onto the wall, damaging the plaster. If the roof has a parapet, it may collapse under the weight of the water.

- According to the type of drain, a funnel is chosen if there is no room under the roof for a horizontal drainage. In this case, the pipes are mounted vertically downward.

You need to pay attention to what type of waterproofing will be used on the roof. The material of manufacture of the funnel must correspond to the roof covering so that the structure can be tightly connected. The most commonly used bitumen coated rubber, which is melted during installation with a gas burner and glued to a similar roofing material.

Installation rules

When installing the outlets, the following requirements must be taken into account:

- The quantity is calculated based on the area. On average, one per 200 square meters. In this case, the diameter of the pipe should be at least 11 cm. It would be nice to make a spare water collector in case the first one gets clogged.

- It is necessary to observe the roof slope - at least 2%. The slope can be carried out both to the center of the roof and to the outer edge.

- When installing the water intake, a small space is left so that the materials do not deform the roof structure when the temperature changes.

- Depending on how many layers the roof waterproofing has, the bituminous apron is sealed between them in the middle, or a piece of insulating material with a size of at least 1 square meter is additionally cut out.

- During installation, additional fasteners are used - bolts, screws, if the structure of the funnel is too light. The material must be made of stainless steel. For cast iron products, additional fastening is not required.

Stages of work on a roof made of soft materials:

- The bottom layer of the roof is being laid.

- A hole is cut along the diameter of the funnel.

- The material is heated with a burner to remove the protective film.

- The funnel is set in place.

- The apron is melted and glued to the bottom layer of the cover.

- If you plan to install a second waterproofing "carpet", additional strengthening of the apron is not required. If the coating is single-layer, a piece of bitumen-treated rubber is cut out and the area around the funnel is closed by heating and gluing the materials.

At the end, a filter for debris and leaves is installed.

The cost of drainage funnels

Several factors affect the cost of water intakes. The more parts, the more expensive, since there must be sealed joints between them. The size of the product plays a role: the price of a water intake funnel with a diameter of 100 mm will be one third more expensive than a cross-section of 75 mm.

Metal products - steel, cast iron - are more expensive. Non-ferrous metals, especially copper, are valued more than all others.

At cost, the most acceptable option is plastic or combined models. They are the most practical, since the soft material compensates for the expansion or decrease in the volume of the metal without breaking the tightness, which is an important indicator of the quality of water intakes.