Comfortable life outside the city at a summer cottage is determined by three communication networks: water supply, sewerage and heating. It is possible to save money in the construction of these systems only on the sewerage system if you choose a cesspool as a collector of drains and sewage. Purely structurally, this is a sealed tank of a certain volume, which is more often assembled from ready-made reinforced concrete rings that are installed on top of each other. The device of a cesspool made of concrete rings must be approached from the position of accurate calculation and competently carried out installation.

Features of cesspools

Previously, sewer tanks were made directly in the ground. Therefore, water partially penetrated into it. Today, according to sanitary standards, this cannot be allowed, because in this way the environment is harmed. It is necessary to build sealed structures.

A cesspool is not a septic tank. There is no waste disposal in it. The sewage simply accumulates and then is pumped out and taken away. And this should be done often enough, so the larger the pit, the less often it will have to be serviced.

Advantages and disadvantages

The biggest plus is the small budget for the construction. If the owners rarely visit the dacha, a cesspool is the best option.

The disadvantages include:

- pumping out is payment for the services of a sewer truck; you can organize an independent export, but this work is dirty and unpleasant;

- very low degree of wastewater treatment;

- an unpleasant smell that will need to be disposed of.

The last drawback is easily solved with a ventilation pipe. It is installed in the cover of a concrete structure.

Design and calculations

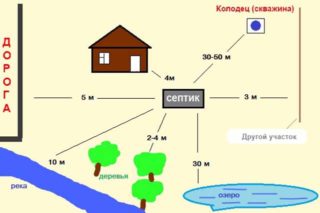

- to the foundation of the house - 5 m;

- to a drinking well or well - 50 m;

- to open reservoirs - 30 m;

- to green spaces - 3 m;

- to the roadway - 5 m.

It is important to ensure the convenience of the access of the sewage truck, therefore, a path is made to the cesspool or a well is built near the fence bordering the village road.

Volume calculation

The calculation is based on two indicators:

- daily water consumption per person, which is equal to 200 liters or 0.2 m³;

- the number of people permanently living in the country.

For example, if 4 people live in a house, in one day the following will be drained into the sewer tank: 0.2x4 = 0.8 m³ of wastewater. Considering that the sewer truck will arrive on certain days, the resulting figure must be additionally multiplied by the number of days. If pumping is carried out once a week, the volume of the tank will be equal to: 0.8x7 = 5.6 m³.

Based on this value, they select reinforced concrete rings for septic tanks and cesspools. They are presented on the market with a large standard size of diameter with a standard height of the product, which is 50 or 90 cm.The diameter varies in the range of 1-2 m.The most popular type that all factories produce: height 0.9 m, diameter 1 m.Its internal volume is 0.71 m³.

To withstand 5.6 m³, 8 rings are required, which is very inconvenient, because they will have to be buried at a great depth. For such a volume, it is better to choose concrete products with a diameter of 2 m, which have a capacity of 2.83 m³. That is, only 2 rings are required.

Cesspool construction technology

Excavation and preparation of the pit

You can dig a pit manually or use the services of an excavator. The second method is quick but expensive. The pit in diameter must be 30-50 cm larger than the width of the rings at least on each side. The bottom of the structure is leveled and covered with a layer of crushed stone and sand 30-60 cm thick. The laid material is leveled and tamped.

Installation of reinforced concrete rings

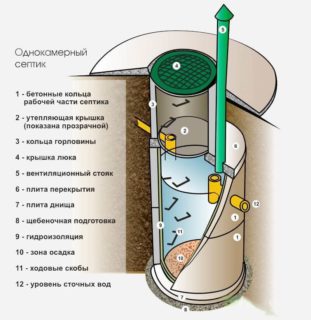

Since the cesspool is a sealed structure, a solid and even foundation must be installed at the bottom of the excavated pit. There are two options here:

- fill the bottom with concrete mortar, having previously laid a reinforcing frame made of steel reinforcement;

- purchase a finished bottom at the reinforced concrete plant for the size of reinforced concrete rings.

The second option is easier in terms of installation and in terms of the speed of installation operations. But, as in the case of concrete rings, the bottom will have to be installed in the well using a crane. The main task is to set it exactly horizontally.

All concrete parts (rings, bottom and top cover) have connecting grooves, which ensure a tight fit of the products to each other and form a sealed lock through which water cannot seep. However, in any case, the connection point must be sealed separately. For this, different materials are used. The most effective is a rubber band, which is placed in the joint lock between the two elements of the well. There are other options as well:

- hydraulic seals, which, when solidified, expand, filling the grooves of the connecting lock;

- special solutions that are applied from the inside and outside of the concrete structure at the joints;

- cement mortar with the addition of liquid glass;

- all kinds of water-based sealants;

- jute, hemp or linen cords impregnated with fiber rubber.

The installation of the cesspool is completed when a cover with a hole for a hatch is installed on the last concrete ring. It is also a ready-made reinforced concrete product manufactured at a precast concrete plant.

In the upper ring it is necessary to make a hole for the sewer pipe. For this, the pipe loop from the house to the pit is pre-assembled. A trench is dug, where plastic pipes are laid at an angle of 2-3 °, since the sewage system in the country is a gravity system. The latter must be insulated. The connected contour determines the location of the hole in the sewer well, which must be made with a perforator. The most important thing is that the pipe entrance must be sealed with a cement-sand mortar.

Operation and maintenance rules

Manufacturers of precast concrete products offer two types of covers: with a ventilation hole and without it. If the second option was purchased, you will have to make a hole with a puncher exactly for the diameter of the pipe to be installed. The length of the latter is at least 3 m.

Prices for concrete rings for cesspools

The cost of concrete rings varies by region. The table shows the average values.

| Model | Diameter, m | Height, m | price, rub. |

| KS10-9 | 1 | 0,9 | 1500 |

| KS12-10 | 1,2 | 1 | 2500 |

| KS15-9 | 1,5 | 0,9 | 2600 |

| KS20-9 | 2 | 0,9 | 5000 |

Prices for plastic cesspool rings are much lower. These products are gradually gaining popularity, but the bulk of suburban real estate owners use concrete parts.