To avoid leaks during emergency depressurization of the sewage system, it is necessary to install several valves and plugs on the pipe sections. They will contribute to an emergency blockage of the flow of wastewater.

Definition and purpose

A sewer plug is a plate or a sphere that covers the internal section of the pipeline.

Gate valves - fittings with shut-off valves in the form of a petal, wedge or knife to regulate the internal pressure or completely block the flow. They are installed mainly when arranging sewerage systems on city-wide lines, risers between floors, pressure stations.

Protective and temporary plugs for plastic lines are mounted to cover lines that are temporarily not used, inspection hatches. They are similar to glasses with a smooth surface and are placed in the holes of branches or tees. The outlet must be completed with a rubber gasket.

The elements are selected from the material that was used for the production of the main pipes - polypropylene and PVC.

Gate valves with mechanical control are mounted at the connection points of individual lines. On autonomous highways, adjustable gates are mounted in external areas in front of the entrance to the septic tank.

Complex devices with auto-locking and regulation are equipped with an electric drive and monitoring devices for the force of the internal pressure. They are used to create the required pressure inside the pressure sewer network.

The installation of locking elements for sewer networks is carried out as planned or urgently to completely or partially block a branch or stop the movement of solid fractions.

Classification of valves

By the type of fasteners, shut-off valves are divided into the following types:

- gate valves with flange joint;

- plugs for rubber gaskets;

- threaded parts;

- welded plugs.

The latter are used to permanently block metal pipelines.

In addition to locking elements mounted outside the sewer pipes, mesh filters are used that let water through and stop the movement of solid waste through the pipeline. To disconnect a separate riser from the common sewer main, pneumatic plugs are installed.

Installation of membrane type check valves made of polymers is often used as a gate valve for external and internal sewerage on a plastic pipe. They can be placed horizontally or vertically. The locking element is a membrane with a rubber sealing gasket; access for maintenance work is provided through the inspection hatch.

Gate valves are used to increase or decrease the permeability of sewer pipes. The difference lies in the complete tightness of the overlap of the inner part of the line, if necessary. For sewage, such a device is preferable, since it can block or limit the flow of a homogeneous liquid and various substances with solid impregnations or gaseous streams.

A cast iron or steel gate valve is installed on both metal and plastic pipes.

Features of the design of gate valves

The advantage of a wedge gate valve is that it can be serviced without particularly complicated steps. A shut-off block with a forward or backward movement at right angles to the wastewater flow closes or opens the way for its movement. When the inside of the pipe is completely covered, the locking wedge deforms due to the applied load, which increases the tightness. However, the wedge reinforcement cannot withstand high flows and can fail due to corrosion.

Gate valves with one or two knives are more reliable. They are used in highways of large cross-section - from 250 mm, steel or cast iron. At enterprises, they are equipped with an electric drive or pneumatic and hydraulic adjustment devices are used.

Unlike the wedge, the gate knife has a sharp edge. Sometimes it is performed in the form of a guillotine. Such details allow you to quickly shut off the flow of even viscous, containing many foreign inclusions of waste.

Gate valves for manual control are of two types - retractable and non-retractable. The first include devices in which the spindle is fully extended out of the pipeline to open the duct. Non-retractable devices include devices with a revolving, as well as a ball mechanism.

Criterias of choice

When choosing a locking device, pay attention to the following points:

- method of regulation and control;

- compliance with the working environment in the backbone;

- section of the pipe;

- terms of Use;

- manufacturer's brand.

For example, there are slide gate valves that show excellent efficiency at high temperatures, up to 400 degrees, but can fail in a cold environment.

The cross-section of gate valves can be different, from 5 to 220 cm, and depends on the area of application and the diameter of the pipes. The working pressure that such devices can withstand should not exceed 60 atmospheres.

Installation rules

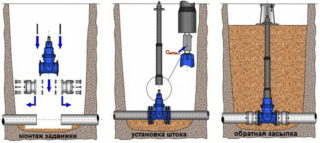

Sliding gate valve installation steps:

- Checking the distance between the flanges, if necessary, sliding them to a size that exceeds the length of the valves by a centimeter.

- Installation of a gate valve between flanges complete with wafer gaskets, fastening bolts and studs for a tie.

- Centering the shut-off element between the flanges.

- Carefully remove the tools used to spread the flanges and evenly tighten the bolts and studs.

Fittings are mounted on a straight section of the sewer main. Avoid the installation of locking elements in places of drops. The stress that can occur at bends negatively affects the tightness of the joint, which can lead to leaks.

If the part needs to be dismantled, first make sure that the knife is in the closed position. After that, unscrew the nuts of the tie bolts and studs, remove the fasteners, spread the flanges and remove the shut-off valves.

Sewer mains and treatment facilities with a long "work experience" require reconstruction with the installation of modern valves. A rational solution is the installation of high-quality slide gate valves. The presence of shut-off elements is also taken into account when designing new pipelines.