To avoid flooding of technical rooms - basement or basement, subsidence of the foundation, as well as erosion of soil in the yard, you can install a gutter, which will direct precipitation to the place that is provided for them - a ditch or storm sewer.

Definition and purpose

You can do without a gutter if the roof is pitched, that is, precipitation, falling on it, is diverted from the back of the house and does not cause significant damage to the walls. If the distance from the supporting structures is large enough, then the gutters are not needed at all.

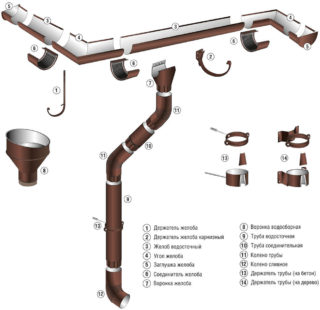

Gutter device

The drainage system consists of water collectors located around the perimeter of the building, into which water flows from the roof. Further, it is directed into funnels connected to the downpipes. The lower end is directed into ditches or a storm drain. The structure is fixed under the roof so that water flows directly into the gutter without overflowing from it - there are special installation rules and calculations for this. Additional consumables - brackets and screws.

Depending on the amount of precipitation in a given region, gutters of various capacities are used, as well as pipes of larger or smaller diameters.

The design can be factory-made one-piece - with corner pieces or plugs so that water does not flow out and everything is sent to the sewer. Homemade gutters are simpler: a gutter collects water from the roof and drains it at the corners of the building. This is a less effective method, as it leads to waterlogging of the soil. In rural areas, rainfall is collected in large barrels and used to water a vegetable garden or flower beds. In suburban private houses, a rain sewer is specially installed for storing water.

Drainage structures are distinguished by the material of manufacture. Here the choice is small:

- metal - copper, aluminum, galvanized steel, ordinary painted steel;

- plastic - PVC or other types of polymer materials.

For any material, it is necessary to select reliable fasteners in the right amount so that the gutter does not sag. This is especially important in winter when ice forms.

Manufacturing materials

There are proposals on the market for arranging factory-made gutters. If you have experience and tools, gutters for draining water from the roof can be made and strengthened with your own hands. The difference in cost. The cheapest are plastic materials - most often polyvinyl chloride. Metal systems will cost more, and copper is the most expensive material. It is also the most cumbersome, therefore, when arranging a copper drain, the method of fastening and the quality of the walls comes to the fore.

Particularly durable structures are made of alloys with titanium, but at a price they exceed the budget level, therefore they are installed less often.

Aluminum

Aluminum metal gutters are highly resistant to temperature changes. The material bends easily, does not corrode.The service life is more than 80 years.

There are disadvantages:

- low coefficient of elasticity - unstable to mechanical damage;

- expands when heated, so the joints are made with a gap so that the entire system does not deform;

- the cost is higher than that of plastic or galvanized steel;

- during installation, it is necessary to insulate all materials that are in contact with aluminum, due to high electrochemical corrosion.

The material is lightweight and does not violate the integrity of the walls.

Cink Steel

One of the most popular materials for the manufacture of drainage systems. This is due to the flexibility, thanks to which you can make designs of varying complexity.

When using a galvanized gutter without additional coating with polymers or coloring compounds, its service life is slightly more than 10 years, therefore, when self-fabricating structural elements, they are first cut out and then covered with a protective layer.

If the gutter is installed after building the house, it is made of lightweight materials in order to reduce the load on the fixtures and walls. Galvanized steel is well suited for this situation as it is lightweight.

Polyvinyl chloride

PVC is a polymer that can be painted in different colors, so it can be easily matched to the overall design of the facade. A homemade structure can be made by sawing a pipe of the required diameter and attaching it to the gutters. It will take longer, but it will be cheaper.

It must be borne in mind that in the cold, PVC becomes fragile. So that the water does not stagnate, a slope of the drain is made inside - one-sided or two-sided. With thermal expansion, changes in size are possible, so it is necessary to make gaps between the joints so that cracks do not form in the heat.

In general, the material is durable and shock-resistant, withstands up to 50 years if properly used - this is comparable to the service life of metal structures. In case of heavy rainfall, water flows silently down the drain, and the inner surface does not have to be cleaned of organic film. The advantage in weight - the structure does not put undue stress on the facade.

Color coated metal

Galvanized steel or polymer coated aluminum looks attractive in appearance and has a variety of colors. A layer of protective material serves as additional protection against corrosion, therefore, it must be handled with care during installation. The slightest scratch or chip will shorten the service life, as the metal will begin to rust and leak there.

Copper gutter - pros and cons

Copper sheet gutter systems are the most durable and reliable because the seamless production technology makes it possible to create one-piece gutters that are not prone to cracking or cracking.

The material does not lend itself to harmful environmental influences. The maximum that can appear on the plates is patina, but its customers order it on purpose, as it gives the effect of antiquity to copper products. Artificially, you can create several shades of patina.

A heating cable can be connected to the copper gutter so that icicles do not form and snow does not accumulate in winter. Copper can be soldered, so mechanically damaged areas are repaired or replaced. The service life of the copper roof and gutter is up to 150 years.

Copper gutters are made round or rectangular - it depends on the design and style of the facade. The softness and plasticity of the material allows you to make products of any shape from it, as well as use it for decoration.

There are 2 standard sizes of copper drainage system - small and large. In the first case, the width of the gutter is 125 cm, the pipe is 90 mm. In the second, a chute is 150 mm, a pipe is 100 mm.

The only drawback is the heavy weight. This requires the installation of additional fittings for the downpipe and reinforced gutter fittings to the roof elements.

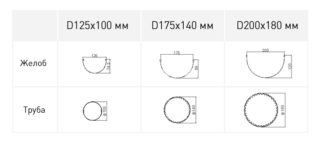

Dimensions of gutters

The greater the slope of the roof, the higher the downward movement of the water will be, so the gutter is made deep and mounted in such a way that the edge of the gutter overlaps the edge of the roof by 2 cm.

The volume of the gutter should correspond to the amount of precipitation that falls in the wettest season.

If you make a drainage system from plastic pipes, select a certain diameter and cut it in half so that each half fits the calculated volume.

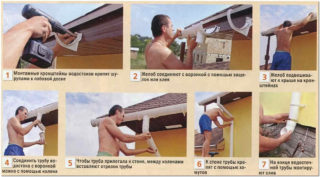

Installation steps

The execution of plastic drainage systems takes place according to the following scheme:

- Workpieces of the required length are made. The edges of the plastic are trimmed.

- Brackets are reinforced with a step of 90 cm along the perimeter of the roof, taking into account the angle of inclination in the desired direction - to the downpipe.

- Fitting fittings for gutters, taking into account the linear expansion. Funnels are drilled.

- The gutter is placed on brackets and reinforced. In places of funnels, glue or rubber seals are used. Plugs are needed to exclude water flow in places where drainpipes are not provided. They are installed taking into account the thermal expansion of the material.

- Downpipes are connected to funnels and attached to the wall. If the pipe length is more than 8 meters, the spacing of the fasteners is 90 cm.

- The end of the drain pipe is directed to the grate of the storm sewer. If this is not the case, then the end is lengthened to bring precipitation outside the pedestrian zone, and at the end, with the help of a candle or blowtorch, a "teardrop" is made so that the water flows in the right direction.

When arranging a metal drain with your own hands, do not use a grinder, as it destroys the protective coating. All work on cutting parts is performed using metal scissors.

The heating cable can be laid in two ways - along the lower edge of the roof and inside the gutters. This maintains a positive temperature and prevents ice from forming.

Product cost

The cheapest are considered structures that are made by hand from aluminum, galvanized steel, plastic. The price of plastic gutters depends on the amount of material used and the complexity of the system, the number of brackets and wall mounts.

Factory models made of polymer-coated metal are more expensive - they are made to order, taking into account the size of the buyer.

The most expensive are copper gutters. They are not available on free sale, since the price of the entire system is too high, and the sizes in each case differ.