The Polair group of companies is the leader on the Russian market for the production of refrigeration equipment with an annual turnover of about USD 150,000,000. The production capacity of the concern is more than 134,000 m2 and are geographically located in more than 20 countries of the world.

From 1990 to the present day, the TM Polair manufacturing plant has been producing medium and low temperature refrigeration equipment for shops and catering establishments in accordance with environmental standards and European quality standards.

- Main lines of air conditioners

- Refrigeration equipment classification from Polair

- Split systems Polair Standard

- Split systems Polair Professionale

- Split systems with microchannel condenser

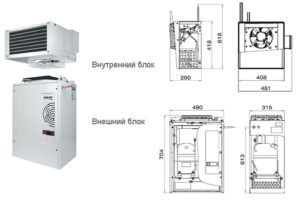

- Monoblocks

- Comparison table of characteristics of popular models

- Polair control panel and air conditioners instructions

- Polair air conditioner error codes and malfunctions

- User reviews

- Positive reviews

- Negative reviews

Main lines of air conditioners

Refrigeration equipment classification from Polair

According to the manufacturer's information, the products of TC Polair are represented by the following samples:

- Monoblock systems (MM109S, MM111S, MM113S);

- Backpack monoblocks with microchannel aluminum capacitor (ММ111R, MB214R, MB109R);

- Ceiling monoblocks (MM109 ST, MM113 ST, MM115 ST);

- Medium and low temperature split system Polair Standard (SM109S, SM222S, SM342S);

- Split systems Professionale with coupling (SM109P, SB216P, SM115P);

- Split systems with microchannel capacitor (SM111M, SB109M, SM115M);

- Air coolers (AS201-1.5, AS202-2.8, AS311-4.5).

Split systems Polair Standard

Dry nitrogen (R 404) is used as a refrigerant in standard refrigeration equipment. Due to this, the temperature regime in the chamber can be in the range from -50From (SM109S) to -180C (SB331S). Condensate drainage from the system is carried out using a drainage 1 m long, which in the basic configuration comes with hermetically sealed soldering at both ends.

Split systems Polair Professionale

Distinctive technical characteristics:

- Thanks to the use of special couplings, which contain a membrane that breaks only when the ends of the pipes and the outlet of the block are connected, a hermetically sealed cold loop of a closed type is obtained.

- When using modern diaphragm couplings for connecting functional units, the installation is carried out without errors.

- Choosing the Professionale series will allow you to get high-tech equipment of exclusively European production.

Split systems with microchannel condenser

Unlike the previous 2 split systems, these devices are equipped with a microchannel capacitor made of a special aluminum alloy as standard. Thanks to the use of this technology, the systems have the following technical characteristics:

Technical features of air conditioners with microchannel condenser:

- the dimensions of the heat exchanger are significantly reduced;

- the weight of the entire set is reduced;

- standard consumption of R404 refrigerant is reduced from 25 to 30%;

- the service life of the microchannel condenser is increased due to the inertness of the aluminum alloy to the water-air environment (does not corrode);

- Due to the smaller amount of refrigerant and, accordingly, the lower load of the compressor unit, the device's own energy consumption is significantly reduced.

Monoblocks

A distinctive feature of Polaris monoblocks is the optional ability to connect a remote control, which allows you to control the system from a distance.

Comparison table of characteristics of popular models

Let's analyze the main modifications of the Polair split system with the subsequent entry of the results into the table.

| equipment identification | SM 109 SF | SM 115 SF | SM 218 SF | SM 222 SF |

| Own energy consumption, kW | 0,46 | 1,056 | 1,21 | 1,02 |

| Supply voltage, V | 220 | 220 | 220 | 380 |

| Productivity m3/hour | 600 | 600 | 1200 | 1200 |

| Condenser motor speed | 1300 | 2600 | 2600 | 1300 |

| Refrigerant parameter, kg | 0,56 | 0,575 | 1 | 0,945 |

| Condensing unit area, m2 | 6,25 | 6,25 | 11,14 | 11,14 |

| Productivity in the "Cold" mode, kW | 0,912 | 1,464 | 1,9 | 2,183 |

| Cost, rubles | 49 795 | 64 612 | 73 549 | 80 482 |

According to the table above, Polair low and medium temperature split refrigeration systems have high efficiency and low own energy consumption, which makes it possible to effectively use such systems in any industrial facility.

Polair control panel and air conditioners instructions

- controller board;

- assembly and circuit diagrams;

- refrigeration unit operating instructions;

- Remote Control.

The main purpose of the buttons and the programming of the system are shown in the photo.

Also, the instruction for the equipment from the Polair company describes in detail how the air conditioner is installed and what difficulties there are during installation, the operating modes of refrigeration equipment, the schedule for maintenance and repair, as well as the frequency of cleaning the filters. In addition to the above, this document describes in detail the functioning of the device's self-diagnosis system, and also decodes the error codes.

Polair air conditioner error codes and malfunctions

Despite the fact that the company's split systems are highly reliable, sooner or later it will be necessary to carry out medium or major repairs.In the event of any malfunctions, the Polair diagnostic system will notify the service personnel using a special code, the decoding of which can be found below.

| Malfunction type, external manifestation and additional symptoms | Probable cause | Remedies |

| The chiller runs in short cycles. The chamber does not maintain a stable set temperature | Air circulation in the condenser fan is impaired due to the small distance between the top of the machine and the ceiling of the room | Check air access to the fan. Provide a clearance of at least 60 cm between the top of the machine and the ceiling of the room |

| Ambient temperature too high | Operate the machine at an ambient temperature not higher than + 40 ° С | |

| The chamber is too densely loaded with food | When loading, ensure free air flow between the food racks | |

| The chiller runs for a long time or continuously. In the refrigerated volume (hereinafter: the chamber) the set temperature is not maintained at a stable | The evaporator is covered with a thick layer of ice | Defrost the evaporator, reducing the time between defrosts |

| Opening doors too often | Reduce the frequency of door openings | |

| The tightness of the chamber is broken | Check door seals and correct if necessary. Check interpanel joints. If there are gaps, cover with sealant. | |

| Frequent loading of the chamber with warm food | Avoid loading the chamber with hot and warm food. Reduce the turnover of products | |

| The chiller does not work, the mains light is off | No power supply at rocker switch terminals | Check the condition of the circuit breaker terminal connections and, if necessary, tighten the screws on the terminals |

| Check the condition of the mains cable and repair if necessary |

User reviews

Thanks to the Internet, you can find a huge number of resources on which owners of Polaris equipment have shared their opinions about the efficiency and reliability of TM Polair. All of them were systematized and summarized.

Positive reviews

- Relatively low price of split systems when compared to Zanotti and Technoblock.

- Convenient location of the condenser, which can be easily washed with Kercher.

- Reliable air cooler that does not rattle during operation with a high-quality fastening.

- Polair split-systems are equipped with French-made L ”unite compressors.

- Low power consumption.

- Connecting and repairing the air conditioner does not take much time and is easily carried out even by a non-specialized Polair team.

- Spare parts for air conditioning are easy to find in any market or in a specialized store with refrigeration equipment.

- Quick and easy setup of the system.

Negative reviews

- Bulky and unaesthetic air cooler housing.

- Unreliable magnetic starters that were installed on early models.

- When installing a monoblock on a camera, it is necessary to take a safety factor (about 30%), since otherwise the compressor will fail after 3 months.

- In the basic configuration, split systems are supplied without refrigerant.

- There is no remote control.

Based on the information presented above, the company's products have an ideal price-quality ratio and have good advantages for using the equipment of this particular manufacturer. If you need higher quality, performance and, accordingly, cost, then it is better to choose and buy imported equipment, such as Rivacold, Zanotti, or Technoblock, which are capable of cooling chambers with a volume of 650 cubic meters (SP marking).

More detailed information about the equipment of TM Polair can be found in the following video: