After purchasing the HVAC equipment, an important point is the installation of the split system How well the work will be done depends on how long and trouble-free the device will be in operation. Therefore, the stages of installation are immediately specified - installation of the indoor unit, the nuances of installing the external, evacuation of the air conditioning system.

Connecting, evacuating and replacing the radiatordo it yourself air conditioner - these are quite complex procedures that require special skills and knowledge.

Air conditioner connection

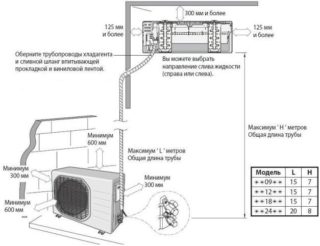

- To lay pipelines and electrical cables, holes with a diameter of about 6 centimeters are drilled in the wall between the blocks.

- Copper pipes are used as pipelines, the characteristics of which are indicated in the manual. Pipes are cut with a special tool that excludes the appearance of metal shavings, flared and bent using a pipe bender.

- The pipe is connected to the attachment point, pre-treated with a sealant.

- Vacuuming is carried out.

- Open the service valve.

- Connect the electrical wires.

- Install the drain hose.

- All pipelines and drainage pipe are rewound with insulation tape.

When vacuuming is necessary

During installation, both units are connected to each other with copper pipes for refrigerant circulation. This is the air conditioner circuit. After laying the copper line, all pipes are hermetically connected and tightened to prevent atmospheric air from entering. Even with great effort to remove air from the pipes by blowing, it will not be possible to completely get rid of it.

Vacuuming the air conditioner is a mandatory procedure both for household devices, where the line length does not exceed 2 meters, and for office or industrial installations, where the length of freon pipes can reach tens of meters.

What is it for:

- air vapors dissolve in oil, which is responsible for lubricating the compressor parts, this leads to a change in the characteristics of the lubricant and it performs its functions worse: it does not form a dense film on the surface of rubbing parts; the mechanism wears out faster and the risk of compressor jam increases;

- moisture changes the chemical parameters of the coolant, which threatens to reduce the performance of the air conditioner, signs of freezing will be noticeable on the circuit.

Vacuuming is carried out before the first start in order to prevent oil contact with air or water residues.

Equipment for evacuation and refueling

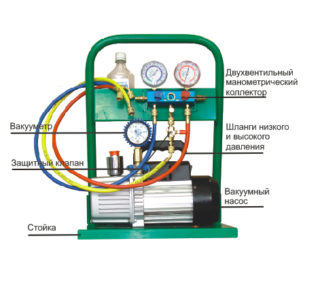

- Vacuum station for air conditioners. Before charging the refrigerant, it is connected to the circuit and dehumidifies it. The pressure gauges on the instrument indicate the vacuum level. In the work of the master, they use two-stage models that are economical in terms of energy consumption, and are easy to install. Heterionic evacuators for air conditioners give good cleaning, but they are rarely used, since they are expensive.

- Gauge manifold.

- A set of screwdrivers and wrenches for working with fittings.

- Freon bottle for subsequent refueling.

The most important device is the pump, which will seal the pipeline. Ease of use creates the weight of the device - the lighter it is, the simpler it is.Models that have a rubber mount to reduce vibration are more convenient to operate.

During operation, the pump consumes oil, so the indication of its level is a useful function for a person who constantly works with the device.

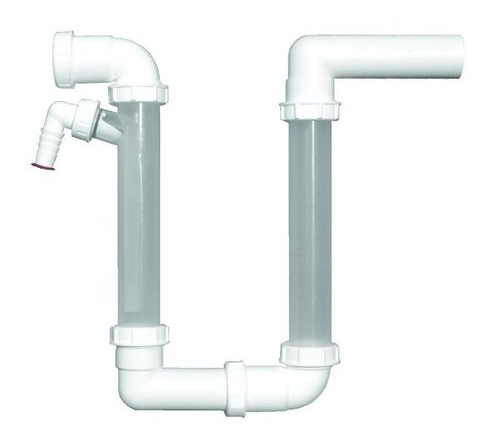

To remove vapors, a valve must be provided, as well as a set of fittings intended for the outdoor unit, through which air is evacuated.

The market is dominated by equipment from German, American, Swiss manufacturers of equipment for HVAC equipment of various price levels. Some Chinese firms supply products that are not inferior in quality to European counterparts, but much cheaper.

Professional repairmen use large refrigerant cylinders, as they often install, fill and refuel the service customers' pipelines. For one-time use, it is enough to buy a small amount of freon so as not to overpay.

Split system preparation

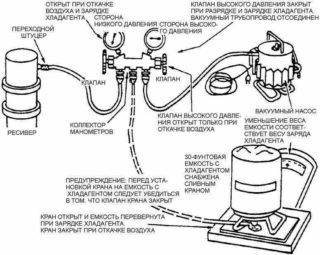

Disconnect the pump before filling the circuit with coolant. Using a hex key, freon taps are opened, the liquid enters the air conditioner circuit, making a hissing sound. How much and what type of refrigerant needs to be charged is described in the manufacturer's instructions.

After filling the pipes with refrigerant, the pressure gauge is monitored for half an hour. During this time, the pressure indicators should not change. Otherwise, look for a leak and re-evacuate and fill the line. Leaks occur due to weak or very strong clamping of nuts on the fittings, poor soldering or flaring of copper pipes. Kinks on pipes can also cause freon leakage, as excessive tension on the metal creates cracks.

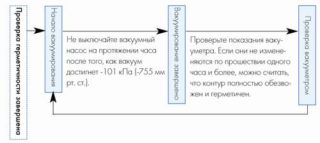

How long does the evacuation process take?

When the indicators in the pipeline stop changing in a certain period of time, you can proceed to filling them with freon.

Do-it-yourself vacuuming of the air conditioner

To evacuate the air conditioner yourself, you need to stock up on low and high pressure hoses.

The end of the hose without the protrusion is connected to the pump. The opposite end, provided with a pin, is attached to the spool of the gas port, after which the pump is started for 10 minutes. At the end of the evacuation, it is necessary to slightly open the valve to start the freon and immediately close it by disconnecting the hose. A small amount of refrigerant will be lost, but this is normal and may be lost when replacing an air conditioner radiator.

During the purging of lines longer than 6 meters, the evacuation method is used to preserve the freon, which would otherwise be released, and refueling is not possible.

After pumping out air and moisture from the pipeline, unscrew the liquid and gas valves until they stop (all seven turns). The joints are treated with soap suds to check for possible leaks.