When choosing a roofing material, take into account the type and shape of the roof, the complexity of installation, the ratio of cost and quality of the product. Ondulin is a corrugated sheet of cellulose impregnated with bitumen, produced by the French company Onduline. Inexpensive and reliable material quickly gained popularity in the Russian market. It is attractive, durable and water resistant. The installation process is simple, the roof can be assembled by hand.

- Characteristics of the Andulin roof

- Varieties of material

- Shingles

- Slate

- Comparison of ondulin with corrugated board and other types of roofing

- Ondulin or corrugated board

- Ondulin or metal tile

- Sheathing step

- Advantages and disadvantages of Andulin roof

- The procedure for fixing ondulin on the roof

- Installation steps

Characteristics of the Andulin roof

In private construction, an inexpensive roofing material, ondulin, has become widespread. The main raw material for its production is pressed cellulose. To give strength, it is reinforced with fiberglass. After dyeing and shaping, the sheets are impregnated with bitumen. The result is a product that resembles colored slate. Some builders call it - euro slate. Multilayer and stiffening ribs ensure its strength, resistance to wind and snow loads. Due to the rough surface, the snow masses do not come down in an avalanche, for example, installation without snow holders.

Products have a standard size:

- length - 195 cm;

- width - 95 cm;

- thickness - 3 cm.

Andulina roofing, made according to quality standards, is moisture resistant and has a guaranteed service life of up to 15 years. With proper installation, it is expected to operate for up to 50 years. Its coloring mineral pigments do not fade for a long time under the influence of sunlight. The material is designed for temperatures from -55 to 110 ° C. The noise insulation index is 40 dB. The roof of ondulin has a low coefficient of thermal conductivity and protects the house well from heat loss.

Composite material is used to cover residential buildings and outbuildings, terraces and pavilions. There is a lot of material on sale that only looks like ondulin. Its characteristics do not meet the factory standards. In order not to purchase a low-quality fake, order a roof covering from the company's official representatives.

Varieties of material

There are two main types of bitumen sheets produced under the Ondulin brand: slate and roof tiles. Despite a similar technology for the production of ondulin roofing material, there are differences between its varieties.

Shingles

The design of the sheet shingles recreates the look of natural tile masonry. The material is durable, withstands snow load up to 960 kg / sq. m, which is comparable to the strength of the rafter system. A multi-layer decorative paint coating that creates a three-dimensional impression gives an attractive appearance to the andulin roof tile. Black pigment is used to form the pattern. The product is available in three basic colors: brown, green and red.

Unlike slate, the sheet has 7 waves, the thickness remains the same - 3 mm, the weight is reduced to 5.9 kg. To install the tiles, 18 special nails with a cast head are required. The cost of products depends on the color.

Slate

Wave sheets of ondulin are only superficially similar to slate. The material contains no asbestos or other harmful components, which makes them environmentally friendly. Euroslate is produced with 10 waves, its parameters are 200 × 95 cm with permissible fluctuations of 3-10 mm.Material weight about 6.5 kg. The manufacturer offers products in two new lines:

- Smart - products have a special lock at the edges of the sheets. A special strip ensures the joint is watertight. The locking system eliminates the need for marking, speeds up work and improves the quality of installation. The product is available in four colors: brown, green, slate, red.

- Diy - a feature of the product is the reduced sheet width. It is 76 cm instead of 95 cm. This made the material 20% lighter. Changing the parameter simplifies transportation, reduces the number of scraps when installing the roof.

On each sheet of ondulin there are markings for driving nails. This is another plus for self-roofing.

Comparison of ondulin with corrugated board and other types of roofing

Ondulin or corrugated board

Corrugated steel sheets are formed on a roll forming machine. The material is offered with galvanized or polymer paint. Profiled sheets have the rigidity and strength required for roofing. Their advantages include:

- the ability to choose a convenient size of the profiled sheet;

- economical consumption during installation;

- strength and long service life;

- incombustibility;

- various shades of powder coating;

- color fastness to fading.

Disadvantages:

- the complexity of cutting, a special tool is required;

- high roof weight;

- noisy in the rain.

The strength of ondulin is low, it can crack from a hail blow or other mechanical impact. The profiled steel sheet withstands static and dynamic loads. The significant weight of the metal material creates a sensitive load on the walls and foundation of the building. The weight of the euro slate is less, it is easier to mount and transport. The main advantage of corrugated board is durability. Such a roof will last 50 years. The Andulin roof will have to be closed in 10-15 years.

During operation, a metal roof is inconvenient due to noise and high temperatures in summer. In addition, condensation forms under the profiled sheets. To neutralize the shortcomings, you will have to install reliable heat and sound insulation, a waterproof membrane. This will increase costs.

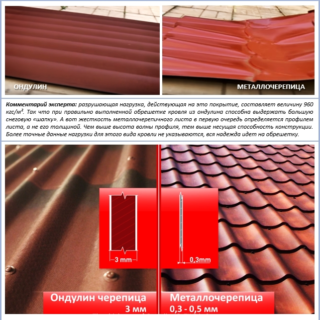

Ondulin or metal tile

The appearance of the metal tile imitates the masonry of a classic clay tile. It is made from a thin sheet of steel with the addition of copper or aluminum. The outer part is covered with a polymer layer that provides metal protection and an attractive design.

Advantages of metal tiles:

- variety of profile and color options;

- respectable type of roof;

- light weight;

- durability;

- Fire safety.

Disadvantages:

- difficulties with installation and high consumption on roofs of complex shapes;

- cannot be used if the slope angle is less than 14 °;

- rusts when cracks appear;

- low sound insulation.

The architectural appearance of a house with a roof made of metal tiles wins in comparison with ondulin. If the owner of the building is ready to pay for expensive installation, then it is better to choose metal tiles. Ondulin will cost significantly less, but the appearance matches the price. In addition to decor, bituminous sheets are inferior to metal ones in strength and fire safety.

Another pair for comparison: ondulin and soft roof. Both materials are made with bitumen and therefore have similar characteristics. At the same time, flexible shingles, due to their elasticity, can be mounted on the roof of any structure. The durability of the material is about 100 years, it does not lose color intensity and water resistance. The pluses include a variety of soft roof designs. The disadvantage of bituminous shingles is their high cost.With a limited budget, it is advisable to give preference to ondulin.

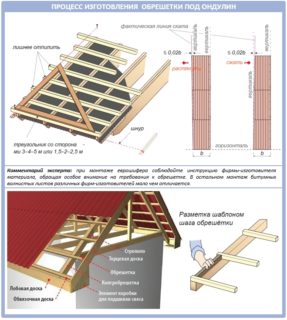

Sheathing step

- 5-10 ° - with a slight slope, the roof experiences an increased snow load, a continuous sheathing of plywood, boards or OSB boards is required;

- 10-15 ° - a beam of 50 mm thick or a board of 25 mm is recommended, an installation step of 45 cm;

- more than 15 ° - they use a board and a beam of similar parameters, the step of the lathing under the sheets of ondulin increases to 61 cm.

The specified interval is the minimum. The manufacturer advises, with a large amount of snow in the region, to make more frequent lathing in order to increase the life of the roof. Experts advise making a template for marking the structure.

Advantages and disadvantages of Andulin roof

Thanks to the verified technology, the ondulin roof has many advantages associated with its technical characteristics:

- Moisture resistance - impregnation with bitumen forms a reliable waterproofing layer that does not allow water to pass through.

- Noise isolation - the structure of the material allows you to damp sound waves. Unlike a metal roof, an Anduline roof does not make noise when it rains. This quality is important when constructing an attic.

- Biological resistance - mold and mildew do not grow on the surface of the sheets.

- Low load - the weight of products does not exceed 3 kg per sq. m, they do not exert significant pressure on the supporting structures and the foundation of the building.

- Environmental friendliness - raw materials used in production do not contain hazardous components.

- Versatility of application - the roofing material is used to cover new roofs, repair, and decorate outbuildings.

- Affordable cost - ondulin is one of the cheapest materials, second only to slate in price.

Ondulin corrugated sheets are used to cover structures of any complexity. The limiting factor is the maximum roof slope.

Disadvantages:

- Strength characteristics decrease with freezing and heating.

- Bitumen and cellulose in the composition of the material contribute to the flammability. Ondulin is prohibited for use in the construction of public and children's institutions.

- Bituminous sheets lose their color brightness after 6-7 years of operation.

A plus is the availability of do-it-yourself installation. The instructions for laying wave sheets are simple and straightforward; no special tools are required for work.

The procedure for fixing ondulin on the roof

Work recommendations:

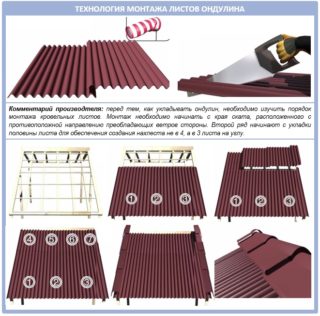

- The covering starts from the edge opposite to the direction of the blowing winds.

- Laying is carried out at positive temperatures, but not higher than 30 ° C, otherwise the bitumen will soften.

- Walkways are prepared for moving on the roof, the material breaks under the weight of a person.

- To make the cut even, the hacksaw is moistened with water or oil.

- With a minimum slope, adjacent sheets are laid with an overlap in two waves, in other cases - in one wave.

- The end overlap is: at 5-10 ° - 30 cm, at 10-15 ° - 20 cm, from 15 ° - 12 cm.

- The overhang of the sheet above the cornice line is 20-35 cm.

- When calculating the material, experts advise adding 10% to the figure obtained on a simple roof and 20% for a structure of complex shape.

Along with the roofing material, additional elements are sold that simplify installation and make the structure reliable and waterproof. These include: ridge, gable, valley covering the apron, ventilation pipe.

Installation steps

The work begins with marking the sheets, a line is drawn on them, along which the fasteners will be hammered.Cutting products with a hacksaw is also performed in advance. The first row starts at the edge of the roof. To fix the sheet, you need 20 special nails with a filler cap. Side and end overlaps must be fixed. The amount of entry of one row to another depends on the slope of the slope, on average it is 15-20 cm.

The second row starts with half of the ondulin. This technology reduces the number of overlaps at the corner joint. In the place of installation of the ridge element, a frequent lathing device is required. The ridge part is fastened with nails to the waves of the ondulin sheet, which is joined to it. Endova is decorated with branded elements, the docking points are additionally waterproofed. To eliminate the gaps between the roofing material and the cornice or ridge, a special material made of polyethylene foam is used.

At the outlet of the ventilation shaft, a special wave element with an ondulin pipe is installed. The base follows the profile of the rest of the products, providing a reliable joint and waterproofing.

Anduline roofing is a modern aesthetic covering of the middle price category. Reliable and safe material allows you to quickly and efficiently mount the roof on a limited budget. With proper installation, ondulin will last for decades.