Baluster is a long-known architectural attribute, which is a low, often figured column. Products are used to support stair railings, various kinds of fences, etc. Such supports can be made of metal, wood, concrete and other materials. When making balusters with your own hands, you can give them any shape - flat, round, square, spiral, etc.

Wooden balusters

Of all the types of balusters, wooden ones are the most common. On such columns, you can depict original patterns, in some cases whole plots.

Structurally, wooden supports consist of the following elements:

- a base designed for attaching the post to the step or under the bolster (special fastening rail);

- the central part, which serves as the main decorative element of any staircase;

- upper part - with its help, the support is attached to the railing or handrails.

The base and the top of the post are made with a small margin, which is necessary to adjust the height when attaching the balusters.

Supports are made of solid wood species (oak, beech, ash, etc.). If they are to be installed on a wooden staircase, they are made from the same material as the steps. This will avoid stresses in the structure when the moisture content of the tree changes during atmospheric influences on the stairs.

Baluster mounting methods:

- through the bolster and the bar under the handrail with screws screwed in vertically;

- on the side of the bolster with a screw;

- directly into the step and handrail through the anchor, etc.

The method of fixing the baluster is determined during its design, so the consumer must decide this issue in advance.

DIY baluster making machines

Making wood balusters with your own hands is a difficult process that requires certain skills in handling wood and the presence of the simplest equipment that can rotate the workpiece along the longitudinal axis. Most often, a lathe with a wide range of cutting tools is used for this purpose.

For the manufacture of balusters of a more complex shape, home-made milling machines, manual or with a copier, are used. The simplest manual router can be made by hand.

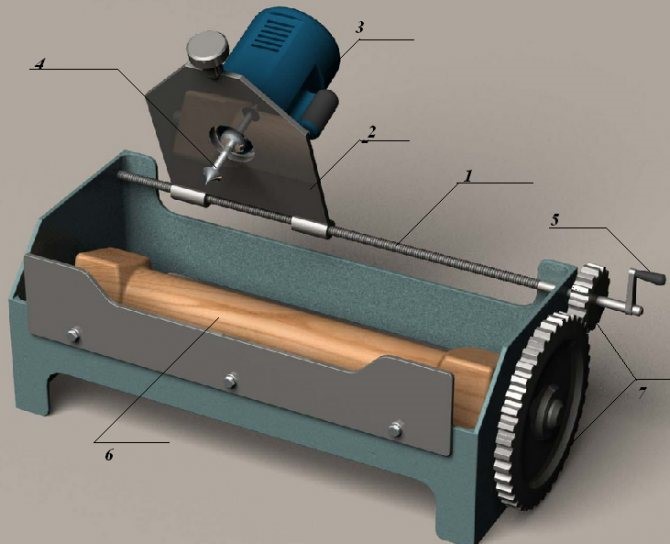

When the handle 5 rotates, the workpiece 6 begins to rotate, and the platform 2 with the rotating mill 4 moves in the horizontal plane, cutting a spiral groove on the workpiece. In this case, the depth and width of the latter depend on the dimensions of the cutting part of the cutter, and the pitch of the spiral depends on the parameters of the gears.

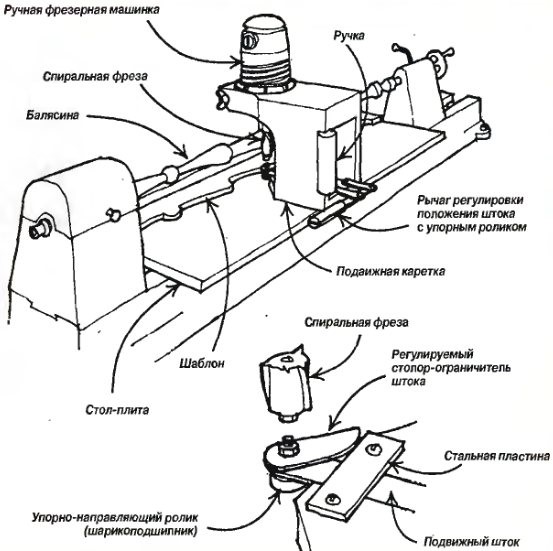

A milling machine with a copier, assembled on the basis of a lathe, will make it possible to obtain balusters of a more perfect shape.

The principle of operation of this device lies in the fact that the depth of the cutouts is not adjusted manually, but with the help of a stop-guide roller moving in a pattern.

A manual milling machine is installed on a movable carriage capable of moving perpendicular to the axis of rotation of the workpiece. In this case, the distance to the center of the workpiece is determined by the stop-guide roller, which moves along the template.

Making flat balusters

Along with the posts of a round or square shape, flat carved balusters made of boards or plywood have become widespread. They can be installed almost close to each other, therefore, when arranging, for example, a terrace fence, it becomes possible to obtain large ornamental patterns. In this case, you will need a set of flat wooden balusters for the terrace, which will not be difficult to make on your own.

Work order:

- Stock up on the required number of blanks.

- Find a suitable ornament to decorate the fence and break it into pieces according to the number of supports.

- Develop blueprints for each baluster.

- Copy each drawing to the corresponding blank.

- Using a jigsaw, cut out the corresponding element of the ornament on each workpiece.

- Finish the balusters to make them smooth and symmetrical.

In conclusion, do-it-yourself balusters from boards are connected into sections and a handrail is mounted. Then the entire structure is varnished.

Metal balusters

Metal balusters are a beautiful decorative fencing of stairs and staircases. A metal support can be made from the following materials:

- Stainless steel. Resistant to corrosion and withstands large temperature fluctuations.

- Cast iron. Such columns can be given any shape, they do not lose their original appearance for many decades. Cast iron elements go well with any materials.

- Iron and its alloys, for example, profile pipe balusters, etc.

All metal balusters are highly flame retardant and durable. When processing metal, it is relatively easy to give it any shape.

Processing methods

Metal for balusters is processed by cold or hot forging, as well as stamping.

The stamping method involves the production of a large number of identical parts required for the arrangement of large areas. In most cases, it is waste-free and therefore economical. When using automatic machines, the cost of balusters is minimal.

When making metal balusters with your own hands using the hot forging method, the workpiece is initially heated to a certain temperature that allows forging metal. Manual forging of metal is a long and expensive process, but it allows you to get an exclusive fence.

Cold forging is a cheap and widely available method of making balusters. The material is processed on special machines using various cutting tools. With this type of processing, heating of the metal is not required, manual labor is minimized.

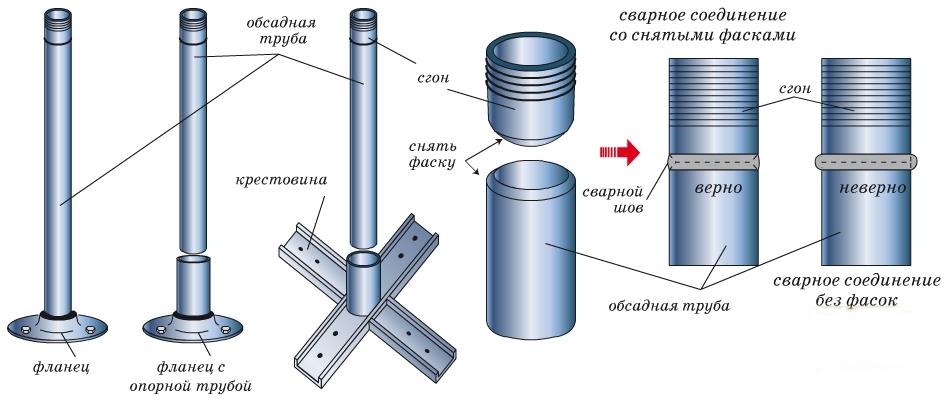

Installation of metal balusters

The sizes of metal fences can be any. To make them look aesthetically pleasing, the thickness of the supports should be within 4-8 cm.

Installation of metal structures depends on the location, weight, and their overall dimensions. There are 4 types of fastening:

- concreting;

- anchor;

- flanged;

- anti-vandal.

Vandal-proof mount is used when arranging street barriers. Concreting is used when it is necessary to mount heavy cast iron fences. An anchoring type of fastening may be needed when installing small-sized fences.

The easiest way to attach metal balusters is electric welding.

Kits of ready-made metal balusters are always sold with fasteners to any material: hinges, brackets, support fasteners, bolts and self-tapping screws.

Making concrete balusters and installing them

With the help of concrete supports, they equip stair railings, balconies and gazebos. They are used to decorate facades. Making concrete balusters with your own hands, for example, for a staircase, is not difficult. The main thing is to adhere to a certain order.

- The preparatory stage is the purchase of cement, preparation of sand, preparation of tools, etc.

- Making molds for casting. To speed up the process, one mold can be designed to cast an entire section of the fence.

- Preparing the grouting solution.

- Pouring and reinforcing concrete into molds.

- Drying the supports and removing them from the mold.

For the installation of fences, first of all, they mark the steps and drill installation holes in them. The diameter of the drilled holes should be slightly larger than the diameter of the reinforcement protruding from the base of the support. Then concrete is poured into these holes and the posts (or a whole section) are installed in place. In this case, each support or section is set vertically along a plumb line. Excess concrete is removed.

After the concrete in the holes hardens, a railing is attached to the fence - they are put on the reinforcement sticking out from the top of each post or section.

Racks made of other materials

For the manufacture of balusters use:

- gypsum;

- natural stone (granite, marble, etc.);

- glass.

Gypsum stucco works well with various types of decor, is durable and can be restored to its original appearance if necessary. Gypsum is resistant to ultraviolet light and, if desired, easily lends itself to surface finishing (staining, bronzing, artificial aging, etc.).

Supports made of natural stone stand out among other types for their sophistication and grace. They are distinguished by their natural beauty and identify with the classic style of decoration, which is characterized by aristocratic luxury and elegance. Columns made of natural stone do not crack, are not afraid of frost, high humidity and sudden changes in temperature, and therefore do not need repair.

Glass balusters embody a stylish design that brings lightness and originality to the design of stairs. To decorate them, they use airbrushing, photo printing or multi-colored illumination.

Never use ordinary window glass to make glass supports. They can be made only from durable laminated glass of the "Triplex" type, which does not shatter into small pieces upon impact, but becomes covered with small cracks.