A heated sauna vat will decorate a family sauna and a professional spa complex. The kadka is similar to the ofuro fonts that are popular in Japan. The rituals are somewhat different, but the purpose of building a bath tub with your own hands is to effectively heal the body and rejuvenate, as in a similar device. The reservoirs are planned during the construction of the bath, otherwise the hot tub can be placed in the open air and the water can be heated with wood.

What is a bath vat

Plain or mineral water is poured into the tank, and a fire is made under the bottom. The liquid is heated to + 45 ° C - + 50 ° C, and flat stones are placed on the bottom inside so that the visitor does not burn himself on the hot metal. The procedure is carried out in an open space, the head is in the cold, the person breathes fresh air, and the body heats up.

Cast iron heats up evenly and gradually, visitors notice a more gentle effect of heat than in the steam rooms of the baths. Herbal decoctions, infusions, mineral and salt solutions are added to the water, so vaping is combined with health improvement.

Capacious containers can be used by a company from three to ten people. For convenience, the vat has tables with floats and cup holders, side benches made of natural wood with comfortable backs and armrests.

Types of bath vats

The hot tub can be installed permanently on stands, logs, or suspended over a fire on a wooden tripod.

You can make a vat for a bath with your own hands of different sizes, provide for the types of heating:

- With a stove. It turns out a quick way to heat up to the required temperature, in about 1 hour. This method is recommended for visitors with children. The ovens are equipped with a protective water shield so that there is no risk of burns.

- With heating from a fire. Soaring and observing experiences are incredible. To reduce the fire hazard, the vats have fire bowls and wind screens to protect against flames.

Reservoirs are made of round, sectional shape, made of different depths. The type of Siberian vat is chosen so as to fully reveal the power of the water procedure.

Material selection

The barrel material affects the operating time. They use metal tanks so that the walls can withstand heating to high temperatures outside while lowering the performance inside with water. Heated hot tubs are traditionally made of stainless steel and cast iron.

The inner surface is not covered with paints and varnishes, since the layer is gradually separated by particles, disappears. Water after use is removed with a hose, and the walls inside are cleaned with a brush with metal teeth. Pieces of peeling paint may appear on the surface the next time you pour water. The layout of stones at the bottom is also not painted; they are regularly taken out, cleaned and rinsed.

Cast iron vat for a bath

Cast iron is convenient and unpretentious to use in the heat of summer and winter. The alloy is resistant to external influences, hardly corroded, and conducts heat well.It does not deteriorate from direct flame, therefore it is used for a long time (up to 15 years), without losing strength.

Bathing tanks are produced by the casting method, when the alloy is poured into a mold. The cooled metal has a smooth surface without seams, which avoids deformation when heated. Disadvantages include long heating times and fragility. For installation, a crane is needed, since the cast iron tank is heavy.

Bath tub made of stainless steel

It is in demand among the owners of bath complexes due to the rapid heating and maintaining a constant temperature, which saves fuel. Chan is prepared from several parts that are welded together. There are tanks made of black steel, but stainless steel does not deteriorate from corrosion, so it is more practical. It is easy to care for the inner surface.

The stainless steel assembly is trusted by experienced welders. If there is no experience, it is better to use ordinary steel, the connection of which will be handled by a novice specialist. The installation can be carried out on your own, since the stainless steel vat weighs a little.

Drawings, dimensions and manufacturing technology

Before manufacturing, you need to make a drawing of a wood-fired bath vat.

The sketches show:

- the design of the font with the dimensions of the components;

- fluid supply and discharge scheme;

- installation method with the stand design;

- interior fittings of the font, seats, backrests, arrangement of footrests.

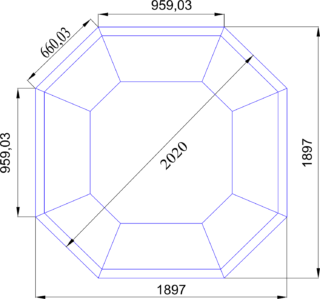

Steel is often used to make six- or eight-sided tanks, which do not turn out to be completely round. The standard size in diameter is considered to be 2.2 - 2.6 m. The depth is chosen at the level of 0.6 - 0.9 m. These are the recommended dimensions, but each manufacturer chooses the dimensions taking into account the material possibilities. What matters is the size of the company for which the vat is designed.

The process of making a bath vat

The bottom of the container in the shape of a polyhedron is cut out of the material for modeling, then the side walls are cut out in the form of a trapezoid. The patterns are made taking into account the slope of the edges in order to get a single structure without distortions and gaps.

Work order:

- the contours of the pattern are transferred to the metal and steel parts are cut out with a small allowance for the width of the cut, use a grinder with a circle for metal or an electric jigsaw;

- check the compliance of the received parts with the patterns;

- the structure is welded in an upside-down position, first, a support is placed under the polyhedron, and it is welded;

- substitute the side walls, grab to it, weld together in stages, beat off the slag from the joints.

The vat is turned over, stability is checked, and decorated.

Installing the vat

Before installation, the area is leveled, a rammed gravel bed is made. Better to put the font under a canopy to protect it from the weather and prying eyes. Under the bottom, a foundation is made of concrete and a support in the form of a cruciform structure made of metal. The reservoir should not tip over when adding water and finding a person. Provide a convenient approach to the vat, a ladder for lifting.

Before internal work, check the tightness and resistance to heat. Water is poured into the vat with a hose, and taken out through the welded-in elbow at the bottom. A reservoir filled with water with a metal ballast at the bottom and a wooden grate (no more than 180 kg) is left for half a day to detect leaks. If they are not there, make a fire.

Indications and contraindications

I recommend bathing in a heated vat for people who have disorders in the functioning of the endocrine and cardiovascular systems.The procedures are suitable for patients with changes in thermal regulation, with malfunctions in the functioning of the respiratory organs. Being in a vat helps to rejuvenate the skin, the integument becomes elastic, taut and fresh.

The procedure allows you to relieve fatigue, heals physically and mentally, heals joints, restores the body after injuries and illnesses.

There are contraindications for bathing in a vat. These include increased blood pressure, decompensated diabetes mellitus, oncology, cirrhosis of the liver, the acute period of a viral infection. Before using this type of recovery, you need to visit a doctor for a consultation.