Facade cladding is chosen depending on the purpose, material characteristics, cost. No matter how well the interior decoration of a frame house is made, it will not look complete without external cladding. The quality of the work also matters in terms of aesthetics.

Features of a frame house

The frame made of wood carries the load from the walls, roof, snow, wind, therefore, the wall filling serves only to insulate the interior space and to enclose the area of the house.

Features of the frame building:

- quick installation;

- energy efficiency of the building, in which heat is retained for a long time, thanks to the well-thought-out design of the walls, floor, roof;

- reduced costs for the construction of a lightweight foundation, for example, a shallow belt, pile or columnar type.

Prefabricated frame houses are delivered to the site in the form of structural elements that are ready to be installed in an assembly position. Many kits have built-in communication parts that need to be connected to common networks.

The need for finishing

The material of the walls gives the frame rigidity, but the infill between the posts does not always look attractive. Finishing from the outside will give the building a beautiful look, and will also additionally protect the shield elements from the surrounding space. Thanks to the exterior decoration, the walls serve for years, regardless of humidity, frost and temperature changes.

To seal the gaps of the frame, sheets of chipboard, OSB, plywood are used, which are also susceptible to moisture. Together with the crate, a waterproofing membrane is laid under the finishing materials with the possibility of the passage of internal household vapors. The outer layer absorbs mechanical shocks, the touch of shoes, and other objects, therefore it additionally provides the strength of the walls.

External cladding options

Facing materials for the facade of a frame structure differ in technical properties, appearance, cost, so the user has to choose from a large list of recommended types.

Finishing options:

- block house in the form of a lining, timber, log;

- ordinary and decorative plaster with painting;

- a layer of ceramic bricks;

- steel, vinyl or wood siding;

- thermal panels with insulation;

- cement-bonded particleboards;

- decorative tiles;

- smart siding.

It is possible to sheathe walls from the outside with the installation of a frame (ventilated layer) or to finish according to the area of \ u200b \ u200bthe walls without lathing. The first option is used to install an insulation layer, if provided by the project.

Block house

This is a planed natural board obtained by sawing logs or in the case of processing boards on a milling machine. The material has a sectional shape of a segment of a circle, on the inner side there are two slots for adjusting the expansion and contraction of the panel with changes in temperature. Belongs to the category of eurolining, gives the house the appearance of a structure folded from logs, a bar.

During production, the material is dried in chambers until a residual moisture content of 15% is obtained, therefore such products can withstand frost and solar radiation. After turning on machines, they are treated with impregnations against decay, moisture, fire.

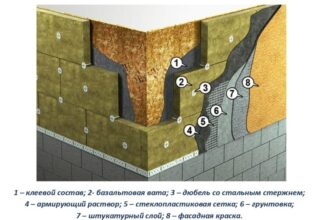

Wet facade

This is the name of plaster, putty, followed by painting with water or oil compounds. The layers are combined with the installation of a slab-type insulation, for example, foam, extruded polystyrene foam. The insulator is glued to the base, then a plaster mesh is laid over it with mortar and a finishing layer is applied.

The application process is not difficult. It is necessary to observe the technology, wait for the drying of the intermediate layers, and prime each one before the next. Plaster gives a lot of room for design choice. The bottom of the house (basement) is made with the same texture and color, the top is different from the pedestal.

A wet facade, together with a heat insulator, does not thicken the facade too much and reliably insulates the interior of the house. Microorganisms and mold do not penetrate through the finishing layer to the wooden frame. There are no cold bridges around the openings of windows and doors, and in the summer heat it will be cool in the house.

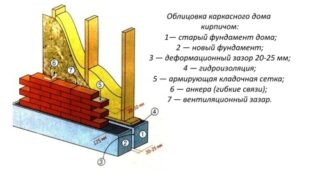

Brick

A layer of ceramic bricks is made in 1 stone or placed in half a brick. The lower trim is insulated from moisture; for this, a galvanized outflow is used. The masonry is carried out from the basement in height to the roof. The finishing layer is bound to the frame of the house by means of embedded reinforcement across the wall. Every fourth row in the masonry is reinforced with longitudinal steel rods with a diameter of 8 mm.

Siding

The frame cladding technology makes it possible to create a ventilated space for ventilation and condensation drainage. Individual strips are joined by means of locking edges, and are attached to the battens through oval holes in the panels.

Siding is distinguished by material:

- vinyl - lightweight, does not rot, resists moisture;

- steel - it is durable, but weighted;

- wooden - environmentally friendly products;

- fiber-cement - weighs a lot, but resistant and environmentally friendly.

For the lathing for siding, a galvanized profile is taken, which is easy to install due to the correct geometry. In the process, they put insulation, insulation from moisture, steam, wind.

Thermal panels

The trim contains an insulating pad located inside the panel structure. The decorative function is combined with insulation.

Thermal panels include layers:

- thermal insulation material;

- decorative coating;

- adhesive base on the back for gluing.

As an insulator, polyurethane foam, expanded polystyrene, extruded polystyrene foam are used. The finishing coating is often performed with clinker under a brick, or porcelain stoneware, marble chips with pigmentation are placed. The service life of the cladding is up to 25 years. The panels are mounted at any time of the year with polyurethane glue.

DSP

Cement particle boards are durable and wear-resistant products. The composition contains cellulose fibers, sand, which are held together with a cement-based binder. Factory-made products are resistant to fire, and do not lend themselves to ultraviolet radiation.

Other positive qualities:

- low moisture absorption;

- ecological cleanliness;

- resistance to microorganisms, mold.

The surface of the panels is made to look like ceramics, painted in different colors. The material does not deteriorate at fifty times of freezing and thawing. The material requires a special tool for cutting, so the installation is trusted by professionals.

Brick tile

For the device of the tiled layer on the wall of the frame structure, preparation is required in the form of insulation with a reinforcing mesh. After that, plaster is applied, ceramic elements or artificial stones are glued to it.With the help of finishing, the plywood walls of a frame house are easily transformed.

They produce types of tiles for brick:

- ceramic;

- clinker;

- flexible;

- cement;

- plaster;

- hyper-pressed.

The material has an average weight category, does not require the installation of massive fasteners. The tiles are simply cut to size using fixtures. They are produced in various textures, colors, they are corrugated and smooth.

Smart siding

The finish is made from sawdust particle boards, so it requires regular maintenance with anti-fire impregnations and antiseptics against microorganisms. The material does not deform during sudden temperature changes.

The cement binder in the base gives a significant weight, therefore sometimes such a cladding requires reinforcement of the existing foundation. For the price, such panels are more expensive than siding and PVC, but cheaper than clinker tiles. Smart siding does not require special cut-to-size tools, unlike cement-bonded particleboards.

Other options

Before sheathing a frame house from the outside, you need to study a few more technologies. For example, gypsum fiber boards are often used. Such panels differ from ordinary drywall with increased strength and resistance to moisture. The material is easy to install and operate, and the disadvantages are manifested in the form of fragility and increased weight.

Fiberboard plates are produced by pressing wood fibers with glue, which is used as natural resins. A relatively fragile material requires regular impregnation and processing. The positive qualities include additional sound and vapor barrier, light weight.

Requirements for materials and nuances of choice

The cladding is made to increase the aesthetic appeal, while the layer performs protective functions.

List of requirements for finishing materials:

- a beautiful view that forms the impression of the architectural style of the building;

- strength and wear resistance;

- resistance to sunlight;

- resistance to moisture absorption and conduction;

- internal and external design must match;

- when facing, it should be possible to use energy-saving technologies.

The material for external cladding on the walls of the house from the frame is chosen so as to meet the planned costs, therefore, the cost is taken into account.

Do-it-yourself frame house cladding

More often they choose a hinged ventilated facade along the crate.

Step-by-step instructions for siding cladding include the following steps:

- wall preparation;

- installation of a heat insulator on the wall;

- installation of the lathing;

- stretching the film;

- setting corners, window, starting and end strips;

- a set of square siding panels.

First, the starting strips are attached (3-4 cm from the surface of the ground or the base) and the elements of the inner and outer corners. Then they frame the window and door openings in the wall, install the finishing strip. They begin to fasten with self-tapping screws starting from the center into oval slots on the bar.

When installing the main finishing layer, each strip is checked with a level and placed along a plumb line. In the area of openings, siding is cut to size. The panels are joined lengthwise using flats or H-connectors. If such parts are not used, an overlap is made by 3 - 5 cm. The top of the panels is snapped onto a special fixing element.