Wood is the best material for building your own home. It makes a warm, environmentally friendly and durable house with a favorable microclimate. There are many technologies for erecting buildings from wood, but the most popular are timber and frame. For an objective choice, it is necessary to compare the parameters, pros and cons of both options.

- Varieties and properties of materials

- Beams

- Frame technology

- Features of the construction of structures

- Lumber

- Wireframe

- Framed

- Uncut

- Post-beam

- Frame-panel board

- The main parameters of frame and timber houses

- The cost

- Environmental friendliness

- Thermal conductivity

- Strength and durability

- Fire resistant

- Pros and cons of timber construction

- Advantages and disadvantages of the frame

Varieties and properties of materials

Before starting construction, they study the characteristics and performance properties of materials in order to make a practical choice.

Beams

When designing a wooden house, a material with a certain processing method is selected. There are several types of timber:

- The usual building material is a cheap material that has been naturally dried and minimally processed to give a square section. The timber does not fit tightly to each other, it is required to strengthen the load-bearing walls. Impregnation with special compounds will have to be done independently.

- Profiled - the products have a smooth surface, clear geometric dimensions, a tongue-and-groove connecting locking system. Such features allow you to reduce the amount of insulation, but at the same time get a tight connection of the crowns. Of the minuses is the shrinkage of the structure.

- Glued - the material is made from several wooden plates glued together under pressure. They are preliminarily dried in chambers. Lamellas are mainly made of coniferous wood. The resulting product has predictable characteristics, cracking, warpage and shrinkage are excluded. A strong connection provides a serrated profile at the ends.

The cost of the house and the speed of its construction depend on the choice of lumber. Expensive glued laminated timber does not require long standing, allows you to immediately finish and move in.

Frame technology

When building a frame house, lumber is necessary when installing straps, vertical posts and horizontal lintels. We use planed non-profiled and profiled timber with a section of 100-200 mm, edged board. The material must undergo forced drying and treatment with an antiseptic under pressure in order for the composition to penetrate deeply into the fibers. The use of raw boards leads to deformation of the structure, the appearance of cracks. In the process of drying, they bend, change their linear dimensions.

For the interior and exterior decoration of the building, a wooden lining and a blockhouse imitating a bar are used. Lumber must be impregnated with an antiseptic and fire retardants. Special treatment reduces the risk of fungus and increases fire resistance.

Features of the construction of structures

The construction of houses from a bar has centuries-old traditions, frame technologies are younger, but have already been verified and tested. When choosing an option for permanent residence, it is worthwhile to study in more detail the features of its construction.

Lumber

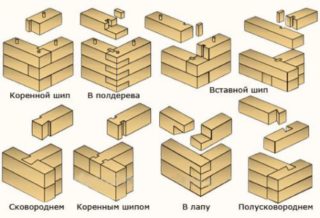

The construction of the house is carried out by the felling method. The parts are joined at the corners "in a cup" or "in a paw". The first method assumes a locking groove with a remainder, the second without a remainder.In any case, the surface of the wood must be flat and smooth. The degree of adherence depends on this, the cracks will reduce the thermal insulation characteristics of the home. The thickness of the walls depends on the width of the lumber. A building for permanent residence requires the use of a bar 200 × 200 mm thick, for a summer vacation, 100-150 mm is enough.

When making a choice in favor of a frame or log house, it is worth considering that a feature of a sawn timber log house is a prolonged shrinkage. Craftsmen leave the finished box for a year, only then proceed to the installation of doors, windows and decoration. If you do not wait for the structure to stabilize, distortions and deformations will occur. An exception is glued laminated timber, it does not need to be given time to shrink.

Wireframe

To build a frame house from a bar, you will need a light foundation - tape or pile. There are 4 main types of construction:

Framed

The technology has several names - frame, pallet or platform. They are associated with the peculiarities of its device. Installation starts from the bottom, each floor becomes a separate platform for the installation of uprights. The walls are assembled horizontally according to the drawings, then raised vertically. The method makes it possible to do the work independently. After the installation of the enclosing structures of the first floor, beams are laid on it, which will become the support of the platform of the second floor. The finished frame is filled with insulation, a wind and vapor barrier is installed, the facade and interior walls are finished.

Uncut

The basis of the frame is a solid timber, which serves as a vertical support for two floors at once. The main difficulty of the method is to install the elements parallel to each other and perpendicular to the base. For construction, a reliable glued beam is taken. The floor beams of the second floor are cut into it, which are at the same time a strapping. House cladding is performed at the end of the frame assembly.

Post-beam

The design is able to withstand high loads and allows the installation of large window and door openings. The technology is called "German" or half-timbered. The frame is assembled from massive beams or planks and floor beams. For reinforcement, vertical and horizontal elements complement the jibs. The details of the structure are fastened by the insertion method; to increase the strength, they are fixed with metal corners and plates. In the classic version, the walls are filled with straw and clay blocks.

Frame-panel board

The assembly of a building using ready-made SIP panels made at the factory is the most technologically advanced. The basis of the structure is a beam, and the openings are filled with mounting plates. They consist of insulation (stone wool, polystyrene, polyurethane foam) on both sides sheathed with finishing materials with vapor barrier films. The finished panels are attached to the timber with self-tapping screws, the holes are filled with foam. The use of panels eliminates the need to work on the internal and external cladding of the house.

The main parameters of frame and timber houses

To choose between a log house and a frame house, you need to compare the main parameters that affect the comfort of living, the cost of construction and maintenance.

The cost

Affordable cost is one of the factors that are named when describing the benefits of frame construction. An attractive price does not always reflect the full scope of work, it is even worse if it is the result of the use of low-grade materials. The estimate for the frame structure largely depends on the finish used. Glued laminated timber is an expensive lumber, but conventional timber significantly reduces costs. In addition, the costs are not one-time, the construction is divided into several stages. You will have to pay for its completion in a year.When calculated correctly, it turns out that the final estimates of the houses do not differ very much.

Environmental friendliness

Health safety is one of the essential selection criteria. Natural material wins in this respect. A favorable microclimate is created in a house made of wood, this is facilitated by the release of natural phytoncides and natural vapor permeability. Residents do not have to install a ventilation system to get fresh air. Treatment of the material with various impregnations will reduce its environmental friendliness, but volatile substances evaporate during the time allotted for shrinkage.

Finishing of frame buildings is carried out from pressed plates containing formaldehyde and other chemical compounds. If the chipboard or OSB boards are made in compliance with sanitary standards, then they are safe. The use of cheap, low-quality materials has a negative impact on health. Heaters in the form of mineral wool also cause concern for owners, they can become a source of allergies. According to the construction technology, the slabs are fenced on both sides with films or membranes, as well as finishing. They have no effect on humans.

Thermal conductivity

A low coefficient of thermal conductivity is a useful quality of a building material, for wood this indicator is 0.08-0.2 W / m * K. Walls made of aerated concrete and wood are almost 5 times more energy efficient than brick structures. Coniferous timber protects the room well from heat loss, but mineral wool and foam do better. Thermal conductivity of materials is 0.035 and 0.04 W / m * K, respectively.

The very technology of frame housing was created to provide the most effective insulation. It is precisely the reduction in heating costs while maintaining a comfortable room temperature that is an important factor when choosing a home for permanent residence.

Strength and durability

A massive solid structure is an obvious advantage of a log house. The heavy weight allows it to withstand any wind load. When choosing a simple project, a dwelling made of wood turns out to be stronger. A complex device with many wide openings and arched passages weakens the load-bearing characteristics of the parts. This happens because not all elements end in a cut.

The strength of the frame structure depends on the thickness and quality of the racks used, and the qualifications of the installers. A well-designed house is resistant to any deformation processes, earthquakes. According to building codes, the period of operation of such a structure without major repairs is 25 years. The same documents for timber options define a period of 50 years.

Fire resistant

Both types of dwellings are constructed of wood, which is a potentially fire hazardous material. In the manufacture of laminated veneer lumber, it is impregnated with fire retardants that prevent fire. Other types of sawn timber should be subjected to similar processing. It is carried out independently.

When assessing the fire safety of a frame house, the combustibility of materials, the features of their installation and the type of cladding are taken into account. The use of foam and other polystyrene derivatives as insulation can have negative consequences as a result of the release of toxic smoke. Mineral wool, on the other hand, serves as an obstacle to the spread of fire. In combination with plasterboard sheathing, it increases fire resistance.

Pros and cons of timber construction

A wooden house looks presentable in any design. It is preferred by lovers of classical and eco-style in architecture.

The advantages of this option include:

- Environmental friendliness - natural wood is safe, provides natural circulation of water vapor. The characteristic reduces the likelihood of mold and mildew in the room.

- Low thermal conductivity - correctly laid lumber maintains the temperature in the house without additional insulation.

- The estimated service life is 50-80 years, in practice it is much longer.

- The attractive texture of the wood does not require the obligatory cladding inside and outside the building.

- If a solid timber is used as a material, then the estimate for the construction is small.

Disadvantages:

- Long construction period due to shrinkage, the possibility of cracking during operation.

- The need for regular maintenance of the walls.

- High price for thick and high quality lumber.

It is difficult for a buyer to determine the degree of moisture and quality of lumber. An unpleasant discovery can be cracking of laminated veneer lamellas if the manufacturer did not follow the technology.

Advantages and disadvantages of the frame

Projects of frame houses differ in architectural diversity, which arouses the interest of consumers. For the building to be warm, reliable and durable, it is important to find professional builders using this technology.

Advantages:

- The construction speed is one of the main advantages of the technology. It takes several months from the beginning of earthworks for the foundation to the end of the cladding. The house does not need time to shrink.

- High energy efficiency - in terms of the reliability of thermal insulation, such buildings are compared to a thermos. This reduces heating bills.

- It is easy to lay any communications within the walls.

- A wide range of architectural solutions, external and internal cladding options.

- With high-quality installation, the house is unpretentious in maintenance, does not require regular repairs.

- You can build a frame at any time of the year.

Disadvantages:

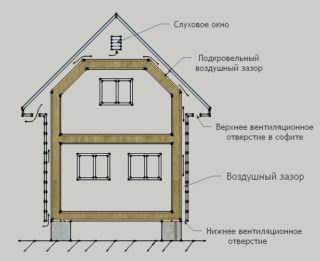

- Complete vapor tightness requires a reliable ventilation device. Otherwise, high humidity will lead to condensation on the walls, the appearance of mold, and rotting of the supporting elements.

- The use of synthetic materials containing toxic components in insulation and decoration degrades the ecological characteristics of the home.

- The design life of a frame house is 25-30 years.

Choosing one of the two options is not easy, each has undeniable advantages and disadvantages. A frame house is a practical modern home with minimal operating costs. A construction from a bar is suitable for connoisseurs of natural aesthetics and environmental friendliness.