Frame-panel houses are built quickly and with minimal financial investment. This opportunity appeared thanks to the development of special technology and materials. The most common option for external cladding of buildings is OSB slabs. Strong and durable panels have an unpresentable look and need finishing. One of the ways to ennoble the facade is painting. In order for the coating to last a long time, it is necessary to choose the right paint and varnish material.

- Description of OSB boards

- The need to paint OSB boards outside the house

- Varieties of applied paints

- Acrylic

- Alkyd

- Oil

- Latex

- Water-based

- Preparatory work

- Required tools and materials

- Features of applying the compositions on the OSB plate with your own hands

- Stain application

- Artificial aging

- Painting with primer paint

- Embossed paint

Description of OSB boards

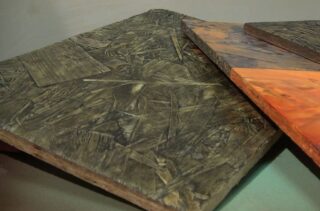

Oriented strand board (OSB) was developed in Canada and is widely used in the construction of houses in North America. The original name of the material is oriented strand board (OSB). These are multilayer sheets made of large-sized coniferous shavings compressed at high pressure and temperature. Phenol-formaldehyde waterproof resins are used as a binder. The addition of wax to the composition enhances the waterproof qualities. Plates can be used to sheathe buildings from the inside and outside.

Products consist of three or more layers in which the chips have different orientations - transverse and longitudinal. This design ensures the strength of the material, resistance to deformation under high loads. OSB is classified by strength and water resistance into 4 groups. In the construction of buildings, OSB-3 is used for facade cladding and roof sheathing. This is the best option in terms of cost / performance ratio. The most durable and moisture resistant products are produced under the OSB-4 brand, but they are expensive. The OSB-1 and OSB-2 models are used for interior work, they are not sufficiently moisture resistant.

The need to paint OSB boards outside the house

Oriented strand boards are 90% wood, therefore they are susceptible to the negative factors characteristic of this material:

- Ultraviolet - direct sunlight leads to softening and evaporation of the resin, cracks appear on the surface of the panels.

- Moisture - constant contact with water increases the moisture content of the sheets, which causes deformation of the edges. Freezing and thawing cycles lead to the destruction of the structure.

- Fungi and other microorganisms - crevices and high humidity are the main factors for the spread of microorganisms. Affected OSBs change color, lose strength characteristics.

To prevent problems that will surely arise after several years of operation of an uncoated house, it is better to immediately finish the exterior.

Varieties of applied paints

To protect the material from moisture and give it a presentable look, paint is used under the OSB plate outside the house. When choosing a paint and varnish composition, the peculiarities of the texture of the plates, the conditions of their operation are taken into account. The material should have good adhesion to wood, UV, moisture, frost resistance. If you want to preserve the texture of the cladding, use transparent varnishes, azure, impregnation. These materials contain UV filters, polymer components, wax. They form a durable glossy or matte finish.Facade paint creates a dense continuous layer, allowing you to give the building a new and interesting look. From the paint and varnish compositions on the market, several options are recommended:

Acrylic

Facade paint containing acrylates is resistant to weathering and UV radiation. When applied, an attractive, even coating is obtained without sagging and sagging. Water-based paints and varnishes are fireproof, withstand negative temperatures, and serve up to 10 years. When choosing how to paint OSB outside a frame house, most owners stop at this option. Note that good surface preparation is required.

Alkyd

The alkyd composition is created by mixing vegetable oils, acids and resins at a high temperature. It dries quickly, is resistant to precipitation, sunlight and frost down to -30 ° C. On the surface of the OSB, the paint forms a thin but durable film. Alkyd enamels are offered at an affordable price. A significant drawback of the material is fire hazard, it ignites easily. When using, it should be noted that application is allowed only on a dry surface.

Oil

The viscous material forms a uniform covering layer, is poorly absorbed into the OSB surface. Solutions based on drying oil have excellent adhesion to wood; after drying, they form a strong film. The coating is resistant to moisture and mechanical stress. The disadvantages of oil formulations include a long drying time, burnout from ultraviolet radiation, toxicity and an unpleasant odor.

Latex

Paints are water-based, contain acrylic resin and silicone-based latex. This is the most expensive version of paintwork materials, but its use is justified by the durability of service and other advantages. The coating dries quickly, is elastic, resistant to moisture and mechanical damage. Ready-to-apply latex formulations are available in a wide range of colors and shades.

Water-based

Water-dispersed formulations are resistant to ultraviolet light, pollution, temperature exposure. They form a polymer film that reliably protects OSB boards from moisture. One of the advantages of water-based paint is low cost. When using the material, slight swelling of the boards is possible.

Preparatory work

The quality of surface preparation affects the life of the finish and the consumption of materials. Slabs that have been outdoors without a protective layer for about a year are covered with small cracks. They need to be sanded well. New OSBs are impregnated with resin and coated with wax, so the coloring composition does not adhere well to them. Such a surface also needs preparation.

The work consists of several stages:

- Grinding - You will need a grinder to complete the procedure. Cleaning the outer layer makes the surface smooth and removes unnecessary relief. OSB-3 requires mandatory removal of the varnish-wax coating, which prevents the penetration of paint into the structure of the board. It is advisable to choose a material without inclusions of bark, which exfoliate over time.

- Putty - oil-glue putty is used to level the boards. It contains acrylates, glue, plasticizers. Particular attention is paid to the grooves in the places where the screws are screwed in and the joints of the panels. After the putty has dried, re-sanding is carried out.

- Priming - OSB coating with special primers protects against moisture, improves adhesion with paint, and reduces its consumption. The solution is applied to the cleaned surface with a brush or roller. When choosing a primer, take into account the type of topcoat. Both materials must have the same base. Priming is carried out in warm weather, the surface must be dry.

After painting the joints of the slabs may be visible The problem is solved by applying a continuous layer of putty or installing decorative strips.The second option is simpler and improves the decorative characteristics of the facade.

Required tools and materials

Application of paint is possible with various tools:

- flat paint brushes;

- short nap roller;

- spray gun.

To change the thickness of the paint and varnish material, you will need a solvent (drying oil, white spirit) or water at room temperature. For work, you will need a plastic bath into which paint from a can, protective clothing, gloves will be poured.

Features of applying the compositions on the OSB plate with your own hands

Painting work begins in warm, windless weather, the recommended air temperature is + 10-25 ° C. It is desirable that there be no direct sunlight, which will lead to uneven drying. First of all, the composition is applied to the edges of the panels. These areas are the most absorbent. Then the entire surface is evenly covered with paint. Movements with a brush (roller) are performed in one direction. It is recommended to apply a thin first coat and avoid wide crossing of the stripes. After the paint has dried, a second coat is applied. If the expected result is not achieved, a third coat will be required.

There are several staining options that can be used to finish the slabs.

Stain application

To emphasize the structure of the material, giving it a deeper shade, will allow the application of stain. The composition is diluted with a solvent, applied with a spray gun. After drying, the surface is covered with polyurethane varnish.

Artificial aging

To give the slabs a stylish decorative effect, special varnishes and patina are used. The process is complex and consists of many stages:

- the surface of the plates is sanded;

- a barrier primer is applied;

- the board is covered with a white matte primer;

- the top layer of the coating is removed with a grinding wheel;

- the plate is processed with acrylic varnish in 2-3 layers;

- a black patina is applied to OSB using a spray;

- the surface is polished to ensure the aging effect.

The work takes a long time, it is necessary to take breaks, waiting for each applied composition to dry. Artificial aging retains the texture of OSB, but without noticeable chip protrusions.

Painting with primer paint

Facade primer-paints for OSB combine the properties of a topcoat, primer and bio-protection. They have the right adhesion and good hiding power. On the textured surface of the slabs, they are applied in two layers, in one the stripes are placed vertically, and the second horizontally. The work is done with a fur or foam roller, previously soaked in water. Before use, the paint-primer is stirred until smooth. After drying, an elastic, non-flammable and vapor-permeable coating is obtained with a service life of up to 10 years. The OSB texture is not visible through it. The composition is sold in white, but there are thousands of tinting options.

Embossed paint

To create a relief coating, silicone, latex or alkyd water-dispersed paints are used. Thick, viscous formulations do not need to be thinned. They are applied to the primed surface with a wide spatula or roller. The layer should be 1.5-2 mm. The relief is created by mineral chips or filler fibers. The hand drawing is created by surface treatment with a dry roller. The intensity of the pressure adjusts the depth of the texture.

OSB painting is the fastest and most inexpensive way to finish the facade. The house can be sheathed with siding or plaster, but the process is time-consuming and costly. The use of paints and varnishes, developed specifically for oriented strand boards, allows you to obtain a beautiful and durable coating.