Aerated concrete is a cellular building material that provides thermal insulation and a favorable microclimate in the house. The operational properties of wall blocks require external finishing after the construction of the dwelling. One of the popular cladding options is plastering. When choosing a suitable mixture, take into account its vapor permeability and compatibility with aerated concrete.

- The need for plastering work

- Insulation of the facade

- Varieties of plaster and their characteristics

- Mineral

- Silicate

- Silicone

- Acrylic

- Cement-sand

- Gypsum

- Required tools and materials

- Plastering aerated concrete outside with your own hands

- When to start finishing work

- Preparation of the base

- Primer

- Plastering

- Reinforcement

- Finishing layer

The need for plastering work

Aerated concrete is an excellent choice for the construction of a private house. The material has low thermal conductivity, frost resistance, large dimensions and clear geometry speed up the construction process. A feature of aerated concrete blocks is the presence of pores. This structure is optimal for heat and sound insulation, but leads to significant moisture absorption. Under the influence of precipitation containing acid impurities, the surface of the facade darkens and becomes heterogeneous. In winter, moisture freezes, creating the risk of cracking.

To protect the walls of the house from negative factors and improve their appearance, decoration is performed. A popular option for decorative design is the exterior plaster of a house made of aerated concrete. It insulates the façade from the weather and gives it a stylish, finished look.

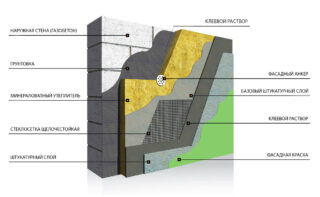

Insulation of the facade

The use of mineral wool is recommended as a heater. It has a vapor permeability comparable to that of aerated concrete. The use of foam plates is undesirable, they completely insulate the walls, not allowing steam to pass from the inside of the house. The situation leads to condensation and getting wet.

Installation of insulation is carried out before the start of work on the plastering of the facade. Installation takes place in a frame or frameless way. In the first case, a wooden bar is screwed onto the walls, between which mineral wool is laid, in addition, the insulation is fixed with disc dowels. The second option involves fixing rigid basalt slabs with an adhesive solution.

Varieties of plaster and their characteristics

Taking into account the peculiarities of aerated concrete, the following requirements are imposed on facade plaster:

- good vapor permeability;

- frost resistance;

- adhesion to aerated concrete;

- compressive strength;

- small percentage of shrinkage.

The plaster should remain intact with slight shrinkage and cracking of the masonry. You can prepare the finishing solution yourself, but it is better to use a ready-made composition. Mixtures from well-known manufacturers Osnovit, Ceresit, SilikatTop, Weber, AEROC, Knauf have all the necessary properties.

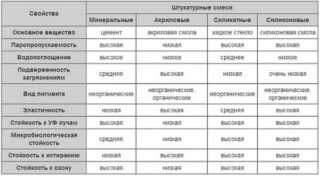

Mineral

The main components of the mixture are: cement, lime, mineral filler (perlite sand, marble chips, dolomite flour). All ingredients are finely ground, so the solution can be applied in a thin layer. The solution possesses the necessary ability to pass water vapor, creates a solid surface, and improves the thermal insulation characteristics of the walls. Mineral plaster can be painted over.

Silicate

The binder component of the composition is liquid potassium glass. The product is offered ready-made, has a pasty consistency. For stabilization and internal reinforcement, marble filler and synthetic microfibers are added. The mixtures are resistant to precipitation, frost, flaking. They have high mechanical strength and create a uniform rough surface. Color pigment can be added to white plaster.

Silicone

The use of a silicone mixture based on silicon-organic polymers is the best option. The composition is resistant to weathering, negative temperatures, does not absorb moisture. The finishing layer is elastic, not covered with cracks, vapor permeable. The plaster is ready to use, additives allow you to create a surface with different textures and colors. It is durable, easy to clean and does not attract dirt. The only drawback of the mixture is its high cost.

Acrylic

Polymer plaster has mechanical strength, due to its elasticity, it does not crack during shrinkage. The advantages of the composition are: frost resistance up to 100 cycles, moisture resistance, ease of application and economical consumption. The main disadvantage of the acrylic mixture is its low vapor permeability. It is allowed to use it provided there is good internal waterproofing of the walls and a high-quality ventilation system of the room.

Cement-sand

The popular and inexpensive mortar of sand and cement is not a suitable option for plastering aerated concrete. There are two reasons:

- Low vapor permeability of the solution - the cement layer passes steam worse than aerated concrete, therefore moisture will accumulate at the junction of the finish or inside the blocks.

- High moisture absorption of porous concrete - the material quickly absorbs water from the solution, the plaster does not have time to gain strength and cracks.

If a cement-sand composition is still used, the walls are pre-primed in two layers to reduce moisture absorption. To increase the elasticity of the solution and its resistance to cracking, tile adhesive is added.

Gypsum

Gypsum-based mixtures are distinguished by good vapor permeability, no shrinkage and environmental friendliness. Compositions are of various grain sizes, intended for manual and machine application. Such a solution quickly hardens and gains strength. It is elastic, easy to sand, creating a smooth surface. The disadvantage is the low resistance to wetting.

Required tools and materials

- Master OK;

- trowel;

- putty knife;

- rule;

- grater;

- brush;

- level;

- kneading container;

- drill with mixer attachment.

For finishing work, you need to buy a primer, a reinforcing mesh, a plaster mixture. Scaffolding, personal protective equipment will be required as auxiliary devices.

Plastering aerated concrete outside with your own hands

Having chosen a material with high adhesion to aerated concrete, vapor-permeable, moisture and frost-resistant, you need to study the technology of applying plaster. Each manufacturer on the package with the mixture indicates the optimal weather conditions (temperature, humidity), gives instructions on how to dilute the composition (if it is not prepared for use).

When to start finishing work

The gas block accumulates moisture during the manufacturing and construction process.After the construction of the building, the material must be allowed time to dry naturally. In addition, the building shrinks in the first six months, so it is undesirable to immediately finish it. First, facing work is performed inside the house, after 2-3 months they begin to plaster the house from aerated concrete outside.

It is recommended to carry out work in the warm season, to avoid rainy and sunny weather. High humidity and direct sunlight prevent the surface from drying evenly. Optimum conditions: temperature 8-30 ° C, humidity not higher than 80%. If the walls cannot be plastered before the onset of the winter period, they are covered with a primer in 2 layers.

Preparation of the base

The walls of gas blocks are quite even, but in places an adhesive composition may appear, which must be knocked down. If cracks are found, the voids in the seams are filled with cement mortar. Remove dust from the entire surface with a brush.

Primer

Plastering

To prepare the solution, you will need a clean container and water at a temperature of 15-20 ° C. The proportions are indicated by the manufacturer of the composition. The dry mixture is poured into water and mixed with a construction mixer. After 5-7 minutes, the solution is mixed a second time. When applying plaster in a thin layer of up to 10 mm, the reinforcement mesh is not required. The composition is applied to the wall with a metal spatula, evenly distributed. The layer thickness should be no more than 5 mm.

Reinforcement

In order to qualitatively plaster the facade without cracking and peeling of the solution, an alkali-resistant fiberglass mesh with 3 × 3 mm cells is used. It is cut into canvases, embedded in a fresh layer of plaster. From above it is leveled with a spatula. The individual sections overlap each other with an overlap of 50 mm. The mesh can be fixed directly to the wall with self-tapping screws. A perforated metal corner profile is attached in the corners. Reinforcing elements should not protrude above the surface to be plastered. A thin leveling layer of mortar is applied over the mesh. The dried surface is primed.

Finishing layer

As a finishing layer, decorative plaster can be used, which forms a textured pattern on the surface. Attention should be paid to the connection of the boundaries of the cultivated areas, there should be no stripes. A wide spatula is used for work, the permissible layer thickness is 4-10 mm. After the composition has set, but until it dries completely, grouting occurs. The surface is smoothed in a circular motion. The plastered facade is painted with a compound for outdoor use.

To decorate a house from aerated concrete blocks, it is important to choose the right material. The mixture must be vapor permeable, moisture resistant, strong and elastic. It is best to buy dry and ready-made formulations of factory production. High-quality products will provide a durable decorative and protective coating.