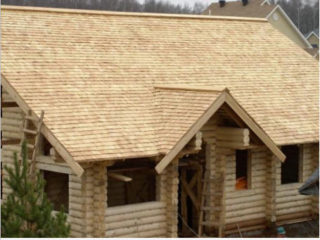

In the old days, wooden roofs were made from a variety of conifers, as well as from oak. Now it is made most often from larch, which is resistant to putrefactive processes and deterioration under the influence of water. When installing a roofing system, it is important to choose the right design scheme and suitable material.

Construction and practicality of a wooden roof

There are several types of timber roof structures. If the dwelling has a load-bearing transverse wall in the middle, and its width is more than 7 meters, use the option with layered rafters. The distance between such elements is 60-200 cm. It depends on the applied loads and on the type of wood used. The board for the rafters should be thicker than 5 cm. On one side, they rest against the wall or rack structure, on the other (from the end) - into the Mauerlat. To increase the stability of the frame, additional fixation is performed using a metal wire. Strengthen it with anchors. Rack elements are tied with boards 20 cm wide to make the system stiffer.

If there is no load-bearing wall, a wooden roof with rafters that do not have support from above (hanging) will do. At the same time, the building should have a minimum width of 8 m. Typically, such a structure is mounted on utility buildings. The support of the rafters with the lower reaches to the wall creates a lot of pressure on it. Staples, nails or bolts are used as connecting parts. To make the base stiffer, the rafters are screed. It must be mounted as high as possible if the attic is planned to be used as a living space.

Another option rarely used in private homes today is a wooden truss. The design is difficult to implement and includes a large number of nodes. Usually it is placed in dwellings with significant spans (up to 20 meters). The beams used for it have a cross section of up to 15 cm.

Varieties of wooden roofs

The board roof can be made from different types of material. They differ in texture, appearance, and partly in the method of attachment.

Schindel

Such boards are detached from the log without disturbing the wood grain. The criterion by which good material is determined is that the growth rings should be at an angle of 30 degrees. It is mounted layer by layer on a continuous crate. Dry the shindle until the moisture content is 18%.

Shingle

Such boards have a wedge-shaped cut. There is a gap in the thickened place where you need to place the corresponding part of the thin part of another element. The sawn shingle looks neater and smoother. The chipped one is more difficult to assemble, but the roof covered with it looks like a well-preserved ancient artifact.

Shingles

It is the easiest to manufacture material used for the arrangement of wooden roofs. It looks like thin (no more than 5 mm) boards. In the past, it was done by splitting wood along the grain. Later, the manufacturing process was mechanized. Installation is carried out in layers on the prepared crate. The latter should have a pitch of 0.2-0.3 m. The layer that is laid on top should overlap the previous one by at least 0.4-0.5 m. Freshly laid shingles have a natural shade of wood, but during operation they have a silvery tone. According to the method of production, the material is divided into several categories.The chipped version is made by hand, this is the most archaic method. The sawn material is made on a machine. Mosaic shingles include wood in different tones. It has better decorative qualities, but also a higher price.

Tes

This material is chosen for its cheapness, ease of installation and repair of the finished coating. It represents unedged boards, which are the result of sawing a log lengthwise. They are very long (up to 6 m) and have a thickness of 0.19-0.25 cm. Due to their dimensions, they can be easily mounted on a regular crate.

Ploughshare

This is a tile made of wood with carved edges, which has the best finishing qualities of this roofing group. Do it only by hand. Most often, aspen acts as a base, acquiring a silver tint and shine during operation. Dwelling houses are usually not trimmed with a ploughshare because of its high cost. It is used to decorate barrels and poppies.

When equipping a roof made of wood, you need to remember that this material is susceptible to combustion. Therefore, the raw materials for the lathing, rafters and roofing must be carefully treated with compounds that protect against fire. The same applies to fasteners and floor slabs. If insulation is used, it should be as less flammable as possible. Special types of mineral wool are suitable.

Device and general construction rules

Before starting work, it is required to prepare a drawing of a wooden roof. It will help you not to get lost during the construction, as well as calculate the required amount of materials. It must be remembered that the roof of the boards is made only on a pitched structure with an inclination of at least 45 degrees. This is due to the need for the outflow of sediments so that they do not spoil the condition of the tree.

Direct contact with concrete must not be allowed. At a minimum, there must be a waterproofing layer between it and the wood.

Structural elements must be thoroughly treated not only with fireproofing, but also with compounds that prevent rotting and mold damage. Combined tools that combine these functions can be found on sale.

When laying out, the boards must be partially overlapped so that when precipitation flows down the slope, they do not penetrate under the roof.

DIY technology for laying and installing a wooden roof

First, the Mauerlat is installed, made of bars. In places where it can touch concrete or brick, roofing felt insulation should be laid. Further step-by-step action plan:

- Parallel to the side walls, square-cut squared beams (0.15 m side) are mounted.

- Racks (0.15 by 0.05 m) are attached to them, the distance between which is identical to the rafter step.

- The extreme rafter elements are placed on the Mauerlat. They should rest on the racks.

- The ridge run is placed on the upper pediment corners.

- Other rafters are mounted. They should rely on racks, skate and Mauerlat.

- The pediment is sewn up with boards and the "pie" of the roof is mounted. Its composition depends on whether it is planned to insulate the roof. It is advisable to do this for a residential building. First, a vapor barrier layer is mounted, then - insulation plates, on top - waterproofing.

They equip the traditional crate, on top of which the roofing is mounted. Do not forget about the partial overlap of the upper layer on the lower one.