Individual construction from foam blocks in the private sector has gained popularity. The material is lightweight, energy efficient, easy to install and affordable. However, in addition to hygroscopicity, it has one significant drawback - fragility and low bearing capacity. For this reason, a wooden floor between floors in aerated concrete house is an excellent way to solve this problem.

Requirements for wooden floors between floors in aerated concrete house

When deciding to overlap the walls with sawn timber, it is necessary to remember that its properties and technical characteristics differ significantly from their reinforced concrete counterparts. However, this material is also subject to GOST and SNiP standards.

Interfloor overlapping on wooden beams in an aerated concrete house must meet the following requirements:

- Strong enough to withstand the weight of people and interior items on top without breakage and deformation.

- Rigidity required to maintain shape throughout the entire design period of operation.

- Resistant to dampness, mildew, mildew and open fire. For this, the raw materials must be properly processed with fire retardants and antiseptics.

- Immunity to temperature and humidity changes. This is achieved by using laminated veneer lumber or beams from valuable tree species.

- Long service life. For private sector structures, it is at least 50 years.

Planning must be approached competently and responsibly. In case of deviation from the established rules, the project will be rejected, and the constructed building will not be put into operation.

Design features

A feature of the construction of buildings from foam concrete is precisely the properties of the blocks. They have low compressive strength and are not designed to carry a point load. If you just put a beam on a wall, under its weight the wall will first crack and then crumble.

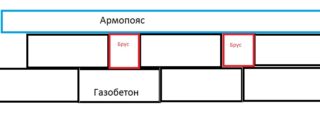

The technology of multi-storey construction from aerated concrete provides for the arrangement of a reinforcing structure at each level - an armored belt. It is a closed reinforced concrete contour, a kind of foundation located along the perimeter of the bearing walls.

Tasks of the armopoyas:

- uniform distribution of vertical pressure over the entire plane of the upper surface of the wall;

- preventing the deviation of supporting structures from the vertical under the influence of horizontal loads and ground vibrations;

- stabilization of the building with uneven pressure on the slab in its different parts.

The armopoyas has a square or rectangular cross-section with a side of at least 20 cm, but not wider than the top row of blocks. The contour is attached to the blocks by means of pins immersed to a depth of at least one and a half rows of masonry. The beams themselves are fixed with pins, corners or long screws.

Benefits of wooden floors

The decision to cover the floors with wooden beams is justified by the numerous advantages of the finished structure.

- Low specific gravity of the material, and, accordingly, relatively little pressure on the walls and foundation.

- The pliability of wood, the ability to give it any shape.

- Conducting construction without the involvement of expensive construction equipment, manual devices are enough.

- Ease of installation, there are no restrictions on the season, temperature and humidity, only the strength of the wind.

- Strong enough to support heavy weight without breaking or deforming.

- Low thermal conductivity, excellent sound insulation properties. There is no need for additional insulation.

- A good basis for arranging a final ceiling on the lower tier.

- A wide selection of lumber, differing in type, grade, section and size.

- Affordable cost, which is much lower than that of reinforced concrete analogues.

- No wet processes, the ability to continue construction immediately after laying the flooring.

Modern technologies and the use of various engineering structures make it possible to minimize factors such as flexibility, susceptibility to fire and decay.

Sizing calculation

Before making the overlap of the first floor in a house made of aerated concrete, you need to carry out careful calculations, choose a construction device, draw up a project, and decide on the type and amount of necessary materials. The maximum dimensions of the beams depend on the type of lumber and the expected load. For a solid board, the maximum permissible length is 6 m, and for glued beams - 12 m. At the same time, 400 kg for residential premises and 200 kg for auxiliary and technical premises is considered the optimal weight per 1 square meter. The standard for the installation frequency of a bar is 60 cm. The load is understood as the mass of finishing material, insulation, waterproofing, people, furniture, household appliances and other interior items.

For self-design, you can use the table, which displays the recommended ratio of the length and section of the beams.

| Purlin length | 2,0 | 2,5 | 3,0 | 4,0 | 4,5 | 5,0 | 6,0 |

| Beam section | 100x150 | 100x175 | 125x200 | 150x200 | 150x225 | 175x250 | 200x250 |

With an increase in the interval between the bar in direct proportion, an increase in its section is carried out.

In addition to the distance and parameters of the bar, the material of its manufacture should also be taken into account. Each type of wood has its own parameters of strength, flexibility, hygroscopicity and durability. Oak has the best performance, followed by cedar, larch and eucalyptus. The lowest performance indicators are for spruce, pine and birch. However, higher quality material is much more expensive. Each developer makes the choice himself, focusing on the purpose of the building, its estimated service life and its financial capabilities.

Installation instructions

- Carry out the markings in accordance with the previously drawn up scheme, cut out the beams of the intended length. It should be borne in mind that the depth of their support should be at least 15 cm. Accordingly, the beam should be 30 cm longer than the distance between the walls.

- Treat wood with antiseptic, fire retardant and hydrophobic agent.

- Make waterproofing. Roll, coating materials or a combination of them are selected. The most popular means are roofing material, roofing felt, linokrom, bitumen, hydroizol. The disadvantage of the coating is that it can be squeezed through and lose solidity.

- Laying the outer beams on both sides of the building. Indents are made 3-5 cm from the outer edge of the walls. After installation, these openings will be filled with thermal insulation.

- Installation of intermediate beams. The step between them can be equal, but it is advisable to reduce it in places of increased load, which are the centers of the rooms.

- Fixing the lag on an armored belt or a support bar. For this, corners, pins or pins are used, which will serve as fasteners for the first layer of blocks on the next floor.

- Laying the openings remaining between the timber with foam concrete. Leveling the surface.Arrangement of the next layer of waterproofing.

In conclusion, the laying of communications is carried out, the arrangement of the rough floor and ceiling, the installation of insulation, the installation of finishing coatings.