Wooden houses attract with a unique microclimate, favorable for humans. They are warm in winter and cool in summer, and the phytoncides secreted by coniferous wood strengthen the immune system. Beam is especially popular among sawn timber. Buildings from it are distinguished by their aesthetic appearance, environmental friendliness, and the speed of construction. Behind the attractive façade of the log structure, there are difficulties that are worth knowing in advance.

- Varieties of logs and characteristics

- Sawn

- Profiled

- Glued

- Pros and cons of a house from a bar

- Features of the manufacture of timber

- Required tools and materials

- Features of building a house from a bar with your own hands

- Design

- Erection of the foundation

- First crown and subfloor

- Assembling the box

- Roofing

- Installation of individual elements

- Internal and external processing

Varieties of logs and characteristics

A bar is a sawn timber with a side section of at least 100 mm. For the construction of wooden houses, manufacturers offer several types of products that differ in the degree of humidity, shape and performance. To choose the best option, you need to study the characteristics of each.

Sawn

Edged or sawn timber is obtained from logs with minimal processing. It is given a square or rectangular shape by cutting off the rounded parts on four sides. The material can be calibrated, resulting in a smooth surface and precise dimensions.

Disadvantages:

- high percentage of shrinkage;

- the need for finishing work;

- labor costs for sealing joints and seams to prevent blowing.

Sawn timber of natural moisture is the cheapest lumber, therefore it is popular with developers.

Profiled

The building material is made from solid coniferous wood: spruce, larch, pine, cedar. Linden, birch, oak are less commonly used. The outer side of the bar is semi-oval, and the inner side is flat. The top and bottom surfaces are cut to the profile. There are 3 types of locks:

- Finnish - there are two side ledges and a platform in the middle, on the opposite side there is a mirror pattern.

- German or comb - the number of spikes has been increased to three or more, they have a trapezoidal section. This design increases strength and reduces heat loss.

Lumber can be dry or naturally moist. Working with it when assembling a dwelling is not particularly difficult, no mandatory finishing is required. There is shrinkage, but not much.

Glued

The most durable type of timber is made by gluing 3-8 lamellas with different fiber directions. Exposure to high temperature and pressure provides the required connection reliability. Lumber can be produced in any size, which is impossible with other technologies. It does not undergo deformation, the shrinkage of the building does not exceed 3%. The main disadvantage of the material is its high cost, it surpasses the profiled analog by almost twice. There is an opinion about the dangers of discharge from the resins used in the manufacture, but if the production technology is followed, there is no danger.

Pros and cons of a house from a bar

When choosing a material for the construction of private housing, its operational characteristics are assessed.Houses from a bar have their own advantages and disadvantages, their ratio will help to determine the best option.

Pros:

- Environmentally friendly and healthy microclimate - natural material has no harmful components, it is hypoallergenic. Good vapor permeability of wood prevents moisture build-up inside the building. Conifers produce essential oils that are beneficial to health. A pleasant aroma constantly accompanies the residents.

- Low thermal conductivity of wood - the structure of the material provides reliable protection against heat loss. The insulating properties of timber are 4 times better than those of bricks. Wooden dwellings quickly warm up and cool down for a long time.

- Aesthetic appearance - the texture of the wood attracts with its original pattern and natural beauty. The polished timber does not need additional finishing; it is enough to open it with varnish or glaze.

- The low weight of the building allows the device of a screw or strip foundation. Such a base will be cheaper.

- Construction speed - profiled and glued beams, manufactured at the factory, are completely ready for work. The building is assembled according to the constructor principle in 1-3 months. If dry lumber is used, it will not take time to shrink.

- Affordable construction cost - wood is one of the most budgetary building materials. Taking into account the device of a lightweight foundation, an estimate is obtained that is lifting for many people.

The construction of a wooden house is possible with your own hands, but for beginners this is a serious task.

Disadvantages:

- When using raw material, construction has to be stopped for a year so that the erected walls shrink. Until the stabilization of the log house, it is impossible to install windows and doors, to carry out finishing. The longest period is required for buildings made of sawn timber of natural moisture.

- Flammability - wood is a fire hazardous material, in order to prevent a building from burning, it is necessary to impregnate the timber with a special composition, follow the rules for installing electrical wiring.

- Cracks appear due to shrinkage and natural drying of lumber. This is an inevitable process that can be easily eliminated with wood putty.

- The need for treatment with antiseptics and impregnations - without treatment, the wood darkens, dries in the sun, and is damaged by insects. The use of special tools will prevent problems. The protection needs to be updated periodically.

Wooden structures from a bar are strong and durable. With proper construction and operation, they serve up to 100 years.

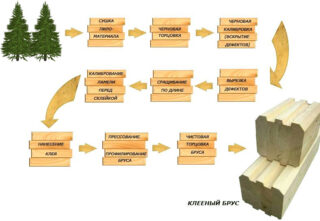

Features of the manufacture of timber

All types of lumber go through the same initial processing stage. Branches, bark and some wood are removed from tree trunks. The workpiece is given a round shape. Further technology depends on the type of product:

- Edged - the workpiece is sawn off the rounded edges. Products are cut according to the established dimensions and sent to the warehouse. They can be natural or chamber drying.

- Profiled - with the help of special milling machines, grooves and teeth are cut on the prepared bar. After processing, the material is grinded to smoothness. Before processing, it is dried naturally for 3-5 months or several weeks in chambers. Humidity should not exceed 20%.

- Glued - the process of its manufacture is laborious, which affects the final cost. The workpieces require chamber drying to a moisture content of 10%. Then they are cut into thin slats. They are glued together in special chambers under pressure. Usually one type of wood is taken, but a combined version with a strong core can be created.

The properties of the material are influenced by the type of wood from which it is made, as well as the conditions of the harvest. The best product is obtained from conifers growing in the north of Russia. The optimal time for harvesting is winter. The trunks have the lowest moisture content, they are not attacked by insects and fungi.

Required tools and materials

The tools required for self-construction can be divided into 3 groups:

- measuring - plumb lines, tape measure, level, square for marking grooves;

- hand-held - an ax, a hammer, a chisel, a plane, a mallet;

- electric - drill, circular and electric (gasoline) saw.

Materials:

- timber (sawn, profiled, glued);

- insulation - tow, jute, moss, synthetic materials;

- antiseptic impregnations, fire retardants, varnish;

- nails;

- roofing material for waterproofing;

- boards;

- construction brackets;

- dowels.

The number of basic and consumables is calculated according to the project data. The use of electrical tools speeds up the construction process.

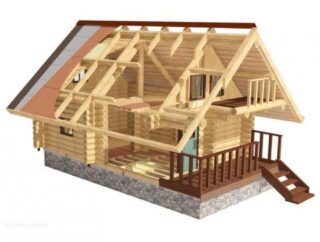

Features of building a house from a bar with your own hands

Building a country house from a profiled bar for permanent residence is a good option, the main thing is to use material of sufficient thickness - at least 200 × 200 mm.

It is possible to build a house from a bar with your own hands, having assembled a team of 3-4 people.

Design

Building a house without a project is unacceptable. It is necessary to create drawings of the building, estimate documentation, specifications. You can take a typical project or apply for the creation of an individual one. In order not to pay for extra material, the calculation is carried out independently according to the distribution. A sketch of a house with all dimensions is performed, the amount of material is calculated manually.

Erection of the foundation

The choice of the type of foundation depends on the load created by the building, the characteristics of the soil, the presence of a basement. A pile-grillage, strip or pile foundation is recommended for wooden housing. The tape type is the most popular, it allows you to arrange a basement and basement. Its device requires digging a trench, pouring concrete into the formwork. Further construction is started after the solution gains strength.

First crown and subfloor

Before laying the first crown, it is necessary to waterproof the foundation with roofing felt. The used timber is treated with an antiseptic. Experts advise to cover it in two layers with impregnations, and use film-forming compounds in the final processing. An oak backing board is laid under the cap. The beam is attached with pins. At this stage, the lag is laid for the floor.

Assembling the box

The walls are erected by stacking the timber in order. Profiled and glued timber has a special locking system. When using a Scandinavian profile, insulation is laid, the German profile is strong in itself. Jute or flax tapes are used as thermal insulation. The joining of sawn timber in the corners occurs in two ways: with and without residue. For each, connection options have been earned: in a half-tree, a warm corner with a root spike.

Along the length, the timber is spliced into a paw or an oblique lock. To connect the rows, holes are drilled and pins are driven in. In places where window and door openings are arranged, technical sawing is performed.

Roofing

The draft roof device includes the installation of ceiling beams and a rafter system. The classic option for a log house is a gable roof. The rafters are supported by the Mauerlat - a bar with a cross section of 150 × 150 mm, attached to the upper rim. Ceiling logs are laid in 90 cm increments and 50 cm out of the walls. A crate is stuffed onto the rafter frame. Its type depends on the selected roofing material. Popular types of roof: tiles, profiled sheets, ondulin.

Installation of individual elements

The installation of windows and doors is carried out taking into account the shrinkage of the house. Fastening is carried out to a special casing box without the use of polyurethane foam. Its sliding design prevents distortion. Insulating material is placed in the slots. Vertical elements (columns, posts) are installed on jacks. The stairs are assembled after final shrinkage.

Internal and external processing

Interior decoration with plasterboard or tiles is possible not earlier than in a year. Outside, the timber is covered with antiseptic and fire retardants. They can be pigmented for decorative finishes. It is recommended to use a polyurethane varnish over the impregnation.