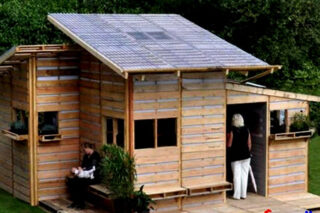

If the owner of the land plot is limited in time and money, an excellent solution is to build a house from pallets with your own hands. The structure is not a standard of strength, but it is quite suitable as a summer cottage or temporary building.

Rules for choosing pallets for construction

Pallets are ready-made fragments for assembling the frame of the floor, walls, ceiling and even the roof. In some cases, blocks can be obtained for free or for a symbolic amount in transport companies, where the planned write-off of expendable property is regularly carried out.

Not all types of such products are suitable for such construction. An important role in the choice of raw materials for the construction of a house from pallets has its origin, storage conditions and operation.

Such products are not suitable for building a house:

- Covered with bright, sometimes light-reflecting paint. Such mixtures may contain toxic substances that are harmful to human health.

- Previously used for the sale of vegetables, in open areas, stored in damp and cold rooms. Such wood absorbs a lot of moisture and unpleasant odors, which can disturb the feeling of comfort and cause allergies.

- IPPC marked. It means treatment with chemically active substances incomparable with residential construction and human habitation.

- With dark spots, mucus blotches, and many small holes. This is evidence of damage to the material by fungus, mold and insects.

When choosing a material for a pallet house, it is necessary to study the condition of the wood. It should be clean, dry and even. The overall gray shade is not a cause for alarm - it is a natural property of the raw material. Also not a problem - spots of dried dirt. It might just be splashing from a passing car.

The best option for purchasing building material is to buy directly from the manufacturer or at a food store where cleanliness, constant temperature and humidity are maintained.

Pallet building options

Conventionally, pallet houses can be divided into two categories:

- Residential. This category includes dacha buildings, outbuildings, summer kitchens designed to accommodate change houses. Initially, it is envisaged that the buildings will have dimensions sufficient for the free movement of a person. In such cases, pallets should be considered as frame blocks with ready-made cavities for insulation and lathing for internal and external cladding.

- Non-residential. We are talking about outdoor toilets, sheds, workshops and gazebos. The size of these structures is limited, but wooden blocks can also be used as a base for all surfaces. You do not have to spend money on insulation, expensive cladding, but use the materials at hand.

It may take more than a dozen pallets to build a house. But as a temporary alternative to brick and timber buildings, this would be a great solution. There were cases when the owners of land plots erected such beautiful and durable houses from pallets with their own hands that they did not want to demolish them. The buildings have served for many years.

Features of building a house from pallets

Structurally, pallets consist of bars on which boards are stuffed.When viewed creatively and from an engineering point of view, the products are very similar to the skeletons used in frame construction. Their sizes are very well suited for the arrangement of window and door openings.

When planning the assembly of a panel structure, the following features of the project should be taken into account:

- It is not necessary to build a strong foundation. A few concrete or brick posts are enough.

- It is better to take material with a large margin. Surplus can be used to make home and garden furniture, many light utility rooms.

- Pallets are large. You should take care of a dry place for their storage in advance, protection from the sun and precipitation. It is advisable to spend a little more, but keep the goods intact.

There are different opinions about the construction technology. Some people prefer to disassemble pallets into parts and erect buildings from pieces. Others use them as they are, supplementing them with the necessary elements. From the point of view of optimization, it is advisable to use assembled blocks, using previously performed work by someone else to your advantage.

DIY step-by-step instructions for building

The first step towards construction is design. A place is chosen for the object on the ground, diagrams and drawings are drawn up, calculations are made. Then the purchase of the necessary materials and missing tools is carried out.

For work you will need:

- roulette;

- a hammer;

- level;

- hacksaw;

- rammer;

- screwdriver;

- drill;

- plane;

- paint brush.

From the materials you need to purchase a bar, a primer and hardware (nails, screws, corners). Before use, the pallets are cleaned of dirt, dried, treated with a fire retardant, hydrophobic agent and antiseptic.

Step-by-step process of assembling a panel house:

- Foundation making. Along the perimeter of the external and internal walls, concrete blocks are laid or columns are made of bricks. Another option is asbestos-cement cast piles.

- Floor installation. Waterproofing is pre-laid on the foundation. A high-quality roofing material is best suited for this. Lags are laid on the supports. It is allowed to stack pallets at once in such a way that their corners rest on the base blocks. Planks, chipboard, OSB or multilayer plywood with a thickness of 16-21 mm are placed and fixed on top of the subfloor.

- Erection of the frame of the walls. A skeleton is made from a bar. First, the vertical posts are installed, then the top harness and crossbars are attached in places for windows and doors.

- Installation of walls. Blocks, starting from the bottom, are inserted between the supports and screwed on the sides with self-tapping screws. For small buildings no more than 3x4 m in size and for children's houses, pallets are placed without a frame, simply fastening together. An inner wall can be fitted for added stability.

- Ceiling arrangement. If the house is small, pallets are stacked on walls and partitions. In another case, logs are first laid, and then blocks are attached to them.

- Internal and external cladding. Outside, block house, siding, or inexpensive plastic panels can be used. Inside the building, it is advisable to sheathe the clapboard, plasterboard, plywood or laminated particle boards.

In conclusion, windows and doors are placed, and the finishing cladding is applied.

Roofing and insulation

Usually, a single-pitched rafter system is chosen for a simple panel structure. It is made without any special problems from the same pallets, fixed between racks that raise on one side and inclined rafters. The frame obtained during the assembly is an excellent basis for the installation of roofing. Given the low bearing capacity of the building, light materials are chosen for arranging the roof - corrugated board, metal, plastic slate.

Installation of thermal insulation is carried out if the building is intended for temporary or permanent residence.After fixing in the system of the house, the ends of the pallets will be closed, so the insulation is inserted into them in advance. The best option would be basalt wool, which is flexible, resilient and has low thermal conductivity.

After the walls and ceiling have been installed, all surfaces from the outside and from the inside are sheathed with a membrane film and only after that the finish is attached. High-quality acrylic paint will protect wood from ultraviolet radiation, insects and moisture.