To build a house from a profiled beam with your own hands, you need carpentry experience. The construction process takes place in several stages, according to the technology. Before work, you should carry out calculations, choose high-quality materials and prepare tools.

Technical description of the profiled bar

Profiled timber is a high-tech material for construction, made of coniferous or larch. It shows its properties both at the time of the construction of the building and during the service. In the manufacture of the material, no glue or other chemicals are used, therefore it is considered "clean" in terms of environmental friendliness.

There are two types of timber - glued and natural moisture. The types differ in manufacturing technology and technical parameters. For example, for the adhesive material, dried boards of different species are used, which are glued together until the desired section is formed. This method has the following advantages:

- precise geometry;

- light weight;

- the possibility of concealed installation of engineering networks;

- nice appearance.

In the manufacture of timber of natural moisture, coniferous trees are used. The peculiarity of the production is the processing of a whole log on a milling machine or other equipment. As a result, the material provides uniform shrinkage and is environmentally friendly in operation. In addition, the product reduces construction and finishing costs.

Material selection criteria

For the supporting elements of the house, high-quality and durable material is needed - wood of I or II grade. When concluding a supply contract with an organization, it is recommended to prescribe the required type of sawn timber in the text. The second criterion that you should pay attention to when choosing a bar is humidity. Undried wood for the home leads to deformation and destruction of the structure. After felling, the tree has a moisture content of 80-100%, so it needs to be thoroughly dried.

Depending on the type of building, the requirements for the limit differ:

- wild felling - 30-40%, after 12 months the humidity level drops to 20-25%;

- milled log - no more than 21%, matured within a year under a canopy;

- glued material - 12-15% is achieved due to preliminary drying of the lamellas.

To be ready for the actual change in the geometry of the timber, read GOST 6782.1-75. The information provided in the document indicates that the amount of shrinkage is directly related to the difference between the initial and final moisture levels.

List of tools and materials

Various companies are engaged in the production of profiled beams, from which you can purchase materials or a ready-to-install kit. When building with your own hands, marking templates, as well as a selection of grooves, must be done independently. The work is carried out at the assembly site, which increases the time for the construction of the box.

To assemble a house, in addition to profiled timber, prepare the following materials:

- mineral wool or other type of insulation;

- edged or unedged board;

- lumber for the formation of the ceiling, floor and interior walls;

- roofing materials;

- window blocks and doors;

- waterproofing;

- staples, nails, and other consumables.

When self-erecting a house from laminated veneer lumber, you will need to rent the following equipment and purchase tools:

- to prepare the site for the foundation - an excavator;

- concrete mixer;

- timber formwork;

- forests, goats, scaffolding;

- hand tools for processing lumber and working with cement-concrete mixture.

The equipment may differ depending on the type of foundation.

After assembling the house, wood surface treatment is available only on certain parts. Protect the walls before laying the timber, i.e. before installation. Use antiseptic compounds.

Construction technology

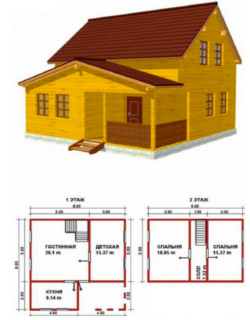

To build a building from profiled timber, develop design documentation. In the papers, reflect the drawings of the future house, materials, technology and tools that you plan to use. Estimating is necessary for the construction of a structure suitable for the given parameters, as well as for calculating materials and financial costs.

When forming project documents, consider the following nuances:

- the organization in which the timber will be purchased;

- storage site for lumber during the construction of the building;

- network engineering;

- the need to contact the architectural department to obtain permission to build a house;

- drawing up a detailed estimate.

When developing drawings for a future building, take into account the cross-section of the timber that will be used in the construction process.

Step by step guide

- Lay the profiled timber according to the project - each element is marked in the assembly kit. For an unambiguous reading of the indices, an instruction is attached. If the blocks are made by yourself, you must first apply the markings.

- First of all, lay the bottom flange, carefully measuring the horizontal position, plane and dimensions of the corners. As a rule, at this stage, the insertion of the floor lags or the construction of supports on the base is carried out.

- Lay the timber in rows sequentially. Install sealing strips to improve thermal insulation and reduce the risk of drafts in the corners. Secure adjacent crowns with pins to prevent horizontal movement and twisting of the tree. However, it is necessary to leave expansion gaps for the shrinkage of the log house.

- Mauerlat is the upper crown of a wooden house, on which the roof truss system is mounted. In view of this, select a high strength bar and carefully fix it. Install the roof covering after installation. Use quality waterproofing materials to reduce the risk of moisture ingress within 3-4 months. This period is set aside for the shrinkage of the house.

- Carry out finishing work after the completion of the natural changes in the geometry of the building. Profiled timber does not require caulking due to precise dimensions and correct drying mode. However, jute in the form of a ribbon can be used to reduce the risk of heat loss. The material has a natural composition and is environmentally friendly.

The interior decoration of the house is carried out with materials, the choice of which depends on the wishes of the owner and the budget.

To maintain the original texture of the wood on the outside of the building, sand and prime the surfaces. Finish with varnish, oil or glaze. It is recommended to use 3-in-1 universal products that combine primer, antiseptic and finish.