The cost of the building determines the material. Silicate and clay bricks, tuff, foam concrete have different costs and different characteristics. A cinder block house is one of the cheapest, but quite reliable options.

Features of the cinder block

Cinder block is a building material created on the basis of coal combustion products in blast furnaces. Over time, the composition has become more diverse: the material includes sawdust, perlite, expanded clay, cullet. Each of the impurities gives the brick special properties. Sawdust and expanded clay increase the thermal insulation properties, concrete - strength, cullet - resistance to aggressive chemicals.

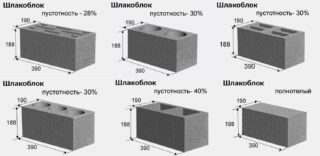

It is better to build a house from a hollow cinder block. It includes cavities, circular or rectangular voids. This reduces the weight of the product, which makes construction easier. There is another advantage: cavities filled with air increase the thermal insulation properties.

Standard block sizes are 200 * 200 * 400 mm. However, the dimensions are subject to change: the length varies from 380 to 410 mm, and the height and width - from 180 to 210 mm.

The appearance of the material is not very attractive: the surface is rough, the color is gray or dirty. Material with sawdust or wood concrete is especially ugly. The cinder block house needs finishing.

Advantages and disadvantages

The cinder-concrete house has pros and cons inherent in such a material. The advantages are as follows:

- The cinder block building is highly durable. If the walls of a building are reinforced, the structure will withstand the strongest winds and storms.

- The building stone has high thermal insulation properties. In the southern regions, such a house does not need additional insulation.

- Due to the porous structure and the presence of cavities, cinder block walls successfully dampen sound.

- The blocks are large but lightweight. They are easy to install, so a beginner can handle the installation.

- Construction time is minimal.

- The cinder block does not burn, does not support combustion and does not fade in the sun.

- The cost of the material is very affordable.

- The building will stand for at least 100 years.

The cinder block house also has disadvantages:

- The material is strong but fragile, especially the sawdust version. Do not hang console furniture or heavy plumbing on the walls.

- The quality of the material directly depends on the conscientiousness of the manufacturer.

- Due to its porous structure, the cinder block absorbs moisture. It is recommended to protect the walls: cover with plaster, for example.

- The material is very unpresentable in appearance. Finishing is badly needed.

Colored varieties of bricks are produced. Their surface is smoother, but the color range is limited.

Cinder block selection rules

- Type of material - a full-size hollow cinder block is taken for the outer wall. In this case, the proportion of hollowness should not exceed 30%, otherwise the strength of the walls will be insufficient. A solid block is needed for the foundation. For partitions, narrow hollow blocks with a high percentage of voids are sufficient: here thermal insulation properties are more important than strength.

- It is important to choose a material with the most accurate geometric dimensions. Cinder blocks are not ideal, especially with sawdust.But the more precise the shape, the better, since less mortar is required during installation.

- It is recommended to request a quality certificate from the seller.

- For a 3-storey building, blocks with the addition of concrete and cement are chosen - they are stronger. A one-story house is built from the lightest blocks.

- The strength and reliability of the material is checked as follows: a brick is dropped from a height of 2 m. A high-quality block does not crack or crumble.

Ideally, a sample of the selected material is sent for examination, where its strength and fragility are determined under pressure.

Necessary building tools and materials

To make building stone you will need:

- Filler - up to 65% of it should be slag. The rest can be replaced by quartz sand, cullet, broken brick, expanded clay, sawdust.

- For the binder, take cement grade of at least M400. You can also use the M500.

- Rectangular shape for blocks - plywood, plastic, boards, sheet metal.

- Concrete mixer.

If you need a lot of material, it is worth renting a vibrating table or vibrating table.

Making a cinder block with your own hands

You can make a cinder block manually. This will require some materials and a curing mold. Metal is preferable: its surface is smooth and the brick is better removed.

- It is important to keep the proportion: 8–9 parts of filler to 1.5–2 parts of binder. Water is about 0.5 parts, but it depends on the ingredients.

- The components are mixed in a concrete mixer. The construction mixer is too weak.

- The resulting mixture is poured into a mold. Before pouring, the walls are treated with solid oil or soapy water. To obtain voids, glass bottles or other cylindrical vessels are placed in the liquid mixture.

- After 5 hours, the bottles are removed, and after a day, the blocks can be removed. The bricks are air dried for 3 weeks. Blocks are covered with foil from direct sunlight.

A higher quality material is obtained on a vibrating table. Molds with cinder concrete are placed here and the machine is turned on for 1 minute. This is enough to tamp the mixture well.

Construction technology

The construction scheme includes several stages:

- foundation construction;

- walling;

- installation of floors;

- facade finishing.

Although the construction of the roof is no longer directly related to the construction of the box itself, it is better not to delay with this. The material absorbs moisture, so the walls need to be protected from rain as soon as possible.

Foundation

The cinder block weighs relatively little compared to its dimensions - up to 31 kg. It does not require a heavy monolithic foundation if the building is not higher than 4 floors. A prerequisite for the base for a cinder block house is height. It should rise 75 cm above ground level. If this is not done, the material will draw moisture from the soil, and the walls of the building will become damp.

The depth of the foundation is determined by the soil and the number of storeys of the building. Usually, its depth should be greater than the depth of the groundwater.

- A trench is dug under the strip foundation. The base is laid not only under the external, but also all load-bearing walls.

- Sand and gravel are compacted to the bottom of the trench. Then he mounts the formwork from boards or plywood.

- The formwork is poured with concrete mixture and left for 7 days. After that, you can build a basement. After 30 days, the formwork is removed.

It is possible to build walls only after the material has completely set.

Walls and partitions

Construction begins with waterproofing the foundation. In normal cases, roofing material is used for this, but you can take liquid waterproofing and film materials.

- Erection starts from the corners. A cinder block is installed in each and leveled using a building level. A fishing line or twine is pulled along the perimeter, which will serve as a marker for leveling the walls.

- A plasticizer must be added to the mortar: it provides higher strength to the walls.Knead small portions of the solution in order to have time to use it.

- Cinder blocks are laid according to the index. The rows of stones are shifted so that the joints of the blocks of the next row are located above the center of the stones of the previous row.

- The solution should be applied with a layer of no more than 15 mm.

- If necessary, the position of the blocks can be corrected: they are knocked out with a mallet to make the joints smaller.

The upper row of walls is strengthened: an iron belt is installed, especially if a material heavier than wood is used for the floor slab.

Finishing

Cinder block walls are ugly and need protection from rain, snow and frost. The following finishing materials are most often used:

- Plaster - both smooth and textured mixtures of any shades are used. The material is pre-treated with a primer so that it does not absorb the plaster.

- Siding - wood, plastic, fiber cement. It is allowed to take even metal, but aluminum is better - it is lighter.

- Ceramic brick is the most expensive, but also the most reliable finishing material. The clinker is completely insensitive to the action of water or frost and provides complete protection for the facade.

A cinder block house is a budget construction option. If the technology for the production of the material and the construction of the building are observed, the service life of such a building is not less than that of a brick one.