Rounded lumber differs from untreated logs in that they have the same circumference along their entire length. During production, the bark is removed, and the excess part of the wood is cut off on the machine. The strength and durability of a house made of rounded logs depends on the accuracy of adherence to construction technology.

- Advantages and disadvantages of construction

- Choosing the diameter of the log

- Required tools and materials

- Preparation for construction

- Building a house from a rounded log with your own hands

- Laying crowns

- Log connection options

- Installation of dowels for logs

- House insulation

- Interfloor ceilings and covering of the house

- Decorating the walls of a building made of rounded logs

Advantages and disadvantages of construction

The advantages include the rapid construction of buildings from processed sawn timber, since the elements are of standard sizes. They are not adjusted during erection, the joints are strong, without gaps and with a tight fit.

The advantages of building a log house:

- Low cost. Release machining only affects some part of the trunk, so the material price is not much higher than the raw elements. Profiled and glued beams undergo more extensive milling and pressing, so their price is more expensive.

- Low thermal conductivity. Compared to brick and concrete, such buildings are warmer and protect the interior from the cold.

- Durability with low weight. The logs in the structure are reliably connected by multiple joints, they are difficult to destroy.

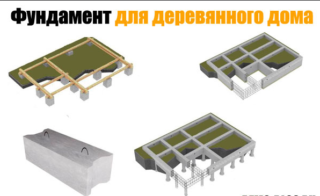

- Saving materials for finishing and foundations. Smooth surface and correct geometry make it possible to reduce the work to sealing joints, sanding and varnishing. The building support can be made in the form of pillars and piles.

- Ecological cleanliness. Natural raw materials do not contain toxic substances. When released, wooden lumber is treated with antiseptics, so their harmlessness is somewhat reduced.

The disadvantages of a cylindrical log home are related to the common disadvantages of wood. These include the disposition to cracking, rotting, warping, fire. To increase durability, use fire retardant impregnations, anti-putrefactive compounds. When erecting, the crowns of the log house are fastened with pins, and screw ties are arranged.

The shrinkage of the building is important for the start of finishing work. Over the course of a year, the crowns fall into place, balance the humidity with the atmospheric indicators, so you need to set aside such a period for changing the size of the house.

Choosing the diameter of the log

There are no uniform standards that control the parameters of the rounded timber and the correctness of the technology. Large factories independently develop production conditions and standards for their enterprise, taking into account the valid GOSTs of state significance. The documents prescribe the requirements for dimensions, quality, storage and transportation conditions.

Diameter is important when choosing lumber, since it determines the thermal conductivity and strength of the walls. The sizes in the section from 160 to 320 mm are produced, the rounded logs of 240 mm in diameter are very popular.

The parameters are chosen depending on the purpose of the building and its location:

- dacha, garage, summer house in the south of Russia 160 - 180 mm, in the European part - 200 mm;

- house of permanent residence, guest buildings, summer cottages in the European part - 220 mm, in western Siberia - 260 - 320 mm;

- in the North, housing with additional insulation - 260 - 280 mm.

The indicator of the working height of the product shows the number of crowns vertically to the roof. Measured from the top point in the section to the groove top. The type of groove matters. The working height of a log with a lunar passage with a section of 240 mm is 208 mm, and in a product with a Finnish groove - 190 mm.

Compensation cut reduces stress inside the log, prevents cracking. The depth of 15 - 20 mm depends on the section of the material.

Required tools and materials

To mark the axes on the ground according to the project of houses from a log, you will need a 10 m tape measure, a hammer for driving pegs, and a string. They use level, theodolite, hydro level. They dig a hole for the foundation using an excavator, and clean the bottom of the trenches by hand with shovels.

Planks for formwork or shields are prepared, which are installed and burst with struts. Reinforcement of the base is made with metal rods with a round or ribbed surface with a diameter of 10 - 14 mm. For backfilling, crushed stone of fraction 20 - 40 mm, quarry or river sand is used.

Concrete is prepared using a concrete mixer. If the volume is small, the pouring mixture can be made manually, which will require a trough, shovels, buckets, stretchers. On top of the foundation, insulation is made from those layers of roofing material on bituminous mastic. From tools you will need a knife, brushes for spreading, tamping, trowels.

Tools for constructing a wooden house from a log house:

- chainsaw, hacksaw;

- electric drill, screwdriver;

- puncher;

- pliers, saw, nail puller;

- square, plumb line.

For the roof device you will need an angle grinder, stapler, level. The types of tools will depend on the roofing material.

Preparation for construction

When there is an approved project, the following steps are taken to prepare:

- clearing the area of trees, other vegetation, leveling the area with a grader or planning manually;

- perform earthworks - digging a trench or foundation pit;

- a bedding of crushed stone and sand is made, respectively, 15 and 10 cm, tamped;

- expose the formwork so that the edge of the boards is 5 cm higher than the planning mark;

- the reinforcement is knitted according to the shape of the foundation (pillar, tape, plate), welding can be used.

A concrete mixture is prepared from cement, sand, crushed stone, water in a ratio of 1: 3: 5: 0.5. The mass is poured into the formwork, helping to distribute it between the reinforcing bars with a trowel. The concrete is covered with sawdust, watered every day with water so that cracks do not appear on the surface of the base. The waterproofing is laid so that the edges hang 3 - 5 cm beyond the perimeter.

Building a house from a rounded log with your own hands

The installation of a wooden house from a calibrated log takes less time than construction from untreated trunks, since the material is selected and marked in advance. The logs form a rigid structure with minimal clearances due to the same diameters.

It takes 6 - 12 months to dry the house (depending on the season of the start of construction). After that, the logs are once again antiseptic from the outside, clogged with tow or hemp crevices. During shrinkage, fibers appear on the logs, so the surface is sanded and varnished several times.

Special jacks are used to adjust vertical structural members. Window and door openings are trimmed with casing - a box that is attached to the ends of the opening by means of a groove connection, and is not fixed tightly.

The southern walls and inner walls are shrinking more quickly, therefore they regularly monitor the process, caulk the cracks.

Laying crowns

The crown is called a belt of logs, which once encircles the building. The crowns fastened together form the vertical enclosures of the building.

Crowns of different types are used:

- salary (bottom) - the first row, laid along the base;

- lower trim (lagged) - forms a rough floor in a building or an interfloor overlap;

- private (wall) - the rest of the belts;

- window - shortened logs for organizing a window opening;

- window-sill, above-window - laid under and above the opening;

- upper strapping - constitutes a support for the rafter system.

The first crown of a planed log house is made of high density material, for example, larch, oak, aspen. A longitudinal cut is first made on the log so that the log fits snugly on the foundation. The elements are impregnated with an antiseptic 2 - 3 times. Check the diagonals between opposite corners, the difference should not exceed 5 mm.

The logs can be placed in the first or subsequent crown, the second option is stronger, since the logs lie on the support girders attached to the foundation. Ordinary crowns are placed similarly to the first, they must coordinate the vertical with a plumb line, the horizontal and check the diagonals.

Log connection options

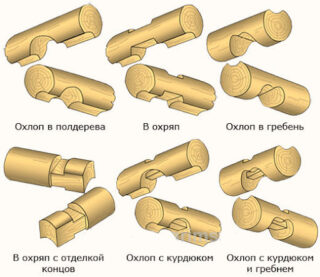

Along the rounded sawn timber is connected by the formation of planting bowls according to the technology used in Russia:

- longitudinal dovetail connection;

- gusset;

- T-shaped connection.

Planting bowls are usually made in the factory to join logs into a half-tree. Cutting into a bowl is distinguished by a protruding residue, this type of fixation increases the consumption of wood.

Varieties are used:

- with a buried ridge (present in the recess of the bowl);

- in a fat tail - there is a recess in the bowl of one log and a protrusion in the bowl of the reciprocal element.

Felling is different in that cutting is done on the lower section of the log, and the upper bar kind of slams it down. Cutting "in okhryap" is distinguished by additional cuts in the landing areas. The method of connection "in the paw" (without residues) is simple, with an undercut and oblique with an undercut.

Installation of dowels for logs

Fasteners are needed to stiffen. Wooden pins are made from the remnants of lumber, but it is better to do it from larch with a diameter of 2.5 cm, while the hole for it is drilled 2 - 3 mm less. The square shape of the element contributes to uniform shrinkage, and the humidity should correspond to the indicator of the bar.

Phased installation of dowels:

- the log is temporarily fixed with nails to prevent displacement;

- make a hole for the dowel, drill through several logs (2 - 3);

- the fasteners are hammered with a mallet, it must enter with effort;

- the first is placed 20 cm from the edge of the timber, all elements are recessed by 2 - 3 mm with a step of 1 - 1.5 m in a checkerboard pattern;

- displacement is done on every fourth bar;

- take out temporary nails;

- after fixing part of the logs with dowels, the elements are upset with a wooden hammer to coordinate the planting.

Steel pins or corrugated bar parts are not suitable for assembling a log structure. Iron rusts, and wood will catch on the corrugated surface and gaps will appear.

House insulation

Distinguish between inter-crown insulation, first and second caulking. Roll material is used between the crowns, while the canvas is put in 1 layer, fixed with a stapler. The width of the insulation is made 10 - 20 mm narrower than the longitudinal cut. The overlap is performed by 50 - 70 mm. In the corners or in front of the openings, the insulation is placed in 2 layers, since in these areas the wood dries more intensively. In bowls, insulation is also laid in 2 layers.

The first caulking is done a year after the construction of a house from a rounded log, after the end of intensive drying. The second and subsequent sealing of the slots is performed if necessary. Caulk external fences, pay attention to sealing the gaps in the bowls.If too much insulation is laid, the crown may rise and it will be necessary to coordinate the height of the other belts with it.

Interfloor ceilings and covering of the house

More often, one-story housing is built from a rounded beam, but there are projects with two floors. Overlappings are formed in the form of a lag crown, when the lags are placed on a support crossbar. The beam is cut into the logs, and the rough floor of the attic or the next floor of boards is laid on the logs.

Sometimes glued laminated timber is used for the support crossbar, which has almost no shrinkage, or the girders are made of paired boards of a suitable section. The beams are cut so that 10% of the groove falls on the lower beam, and the remaining distance is distributed in the log of the next crown.

The roof is made massive, with a solid rafter system. The rafters are not placed on the last log, but they are brought inside the timber - so the joint will not be blown through. To compensate for the shrinkage, the rafter legs are mounted on the Mauerlat using a sliding fixation, and the ridge beams are attached by the same method. Insulate the under-roof gap.

Decorating the walls of a building made of rounded logs

Finishing processes include grinding, ebb installation, laying of communications, interior cladding. The laid wall is sanded to smoothness. Rounded logs have a high-quality surface, but installation and shrinkage can lead to roughness on the sides.

The ebb is needed to protect the lower crown. It is made of galvanized, plastic, mortar, copper. They put the element so that there are no gaps between it and the log, if any, use a silicone sealant. The ebb tide is placed at an angle to the wall, fastened with self-tapping screws.

It is better to install pipelines and power grids after the house has shrunk from a log, and during the construction process, leave the required niches or gaps for them. Be sure to comply with the requirements of fire safety in wooden buildings. Inside, the decoration is carried out in accordance with the design project or the wishes of the owner.