A rough facade finish is the basis for an attractive and durable finish. Applying a high-quality putty allows you to level the base, smooth out irregularities and hide cracks. It provides reliable protection of walls from moisture and other external influences. To choose the appropriate option, you need to study all types and features of the material.

What is facade putty and requirements for it

Front putty is a pasty or dry construction mixture, which is used to level the outer walls of the building before installing the finishing. It is applied before painting and decorative plaster. The concrete or brick used in the construction of the building walls is hygroscopic and gradually absorbs moisture. The house becomes damp, the heat quickly goes away. With the onset of frost, moisture freezes, creating cracks. Wall decoration allows you to avoid all of these problems.

There are special requirements for facade putty for outdoor use:

- high adhesion to various surfaces;

- moisture resistance;

- the ability to withstand multiple cycles of freezing and thawing;

- ease of application;

- maintaining elasticity for a long time;

- compatibility with paints and varnishes;

- increased strength after drying;

- vapor permeability.

When choosing a material, it is important to study its technical characteristics. Manufacturers indicate the basic data on the packaging. You should pay attention to the following features:

- Mixture consumption per 1 sq. m - information will be required to calculate the total volume of purchased material.

- Recommended layer thickness - insufficient value will not provide the desired characteristics, and with an increase in the parameter, the solution may fall off.

- Possibility of operation at subzero temperatures - the composition must be frost-resistant.

- Drying time - the finisher, knowing this parameter, is oriented. How much mixture to dilute on a certain area. If you make a lot of mortar, it will set faster than it will hit the wall.

The putty for the facade contains cement or gypsum, additives (plasticizers and modifiers), mineral fillers. Soap, varnishes, chalk, glue are also added to various mixtures. The ingredients vary depending on the specialty of the top filler. In moisture-resistant compositions, there are more water repellents, frost resistance is increased with plasticizers.

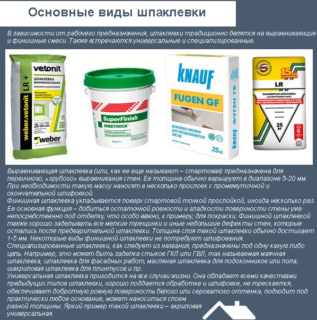

Types depending on the size of the fillers

Starting

The mixture has a coarse-grained structure and is applied in a thick layer. Its purpose is to perform the initial leveling of the surface. The mortar should smooth out bumps and cracks. It has good adhesion to bricks, concrete, wood. The composition is applied in a layer up to 20 mm, dries quickly.

Finish

Finely dispersed filler allows you to create a thin and smooth layer for decorative finishing. The mixture is easy to apply, has good adhesion, does not crack after drying. The solution is applied in a layer of 2-4 mm. As part of the front finishing putty, it is usually white cement or gypsum, so it is white.

Viscosity varieties

Cement

The mixture consists of cement, silica sand, cellulose fibers and modifiers. Marble chips and other finely ground mineral fillers are added to the finishing material. After applying the facade cement putty, a durable waterproof layer is formed. The solution is resistant to frost and temperature fluctuations. The disadvantage is the tendency to shrink and crack.

Latex acrylate

Latex mixtures are sold ready-made. They are used for plaster, concrete or plastered substrates. The material is plastic, it is applied with a layer of up to 3 mm, it does not crack. Recommended for interior work. The disadvantage of the latex mixture is the high price.

Oil and glue

The paste-like composition contains drying oil, glue, chalk, plasticizers and water. Additionally, manufacturers introduce antiseptic agents, coloring pigments. The mixture has an increased covering ability. Adding glue to the strength and durability of the finish. Oil mixtures do not tolerate moisture well.

Acrylic

The putty is odorless, environmentally friendly and easy to sand. The mixture can be applied in layers up to 5 mm. It is waterproof, plastic, perfectly levels and fill the surface. There is no shrinkage after the solution has dried.

Types of mixtures

According to the consistency, external putty for walls is divided into two types: dry and pasty. The first version of the material requires dilution, and the second is already ready for use.

Pasty

Ready putty is packed in plastic containers - buckets or cans. It is water-dispersed or contains polymers (latex, silicone). Paste mixtures are elastic, they can be applied to the wall without any problems. By design, they are starting, finishing and universal. The product can be stored unopened for a long time. The only drawback of the material is the high price.

Dry formulations

The dry mix is sold in paper bags of various weights. Before work, it is diluted with water according to the manufacturer's instructions. To impart homogeneity during the dilution process, the composition is continuously stirred.

The advantage of the powdery composition is the affordable cost, as well as the ability to change the thickness of the solution, to make it in the required volume.

Rules for applying facade putty

The dry composition is diluted in water using only a clean container. The pasty mixture is thoroughly mixed. Drying time of the prepared putty is from 30 minutes to 3 hours. First of all, the existing holes and cracks are closed. After drying, the composition is applied to the entire wall. If the first layer failed to remove irregularities, then the procedure is repeated. After a day, the starting putty dries up, you can proceed to the final stage - applying the finishing mixture.

It is not recommended to carry out finishing work in the sun or rain. High humidity and temperature negatively affect the performance of the putty.

Famous material brands

On the market of building mixtures, there is a huge selection of facade putties of Russian and foreign production. Materials differ in quality and price category.

Company Ceresit - a well-known brand in the market of materials for finishing and waterproofing buildings. It produces putty in the form of dry mixes and ready-made polymer-based compounds. Ceresit CT 29 starting filler is offered for leveling the facades. The polymer sand composition is reinforced with microfibers, is plastic, has excellent adhesion.It is used for concrete and brick substrates, as well as for polystyrene and mineral wool insulation boards.

Ceresit CT 225 is suitable as a finishing mixture. The composition is frost-resistant, moisture-resistant and durable.

Facade mixtures of a German company Knauf Multi-Finish cement-based are white and gray. They use polymer additives and reinforcing fibers as fillers. Layer thickness for continuous leveling is 1-3 mm. The material is resistant to weather conditions, does not shrink and cracks. The putty is of high quality and affordable cost.

Facade filler is used for finishing private houses and public buildings. It creates additional protection against moisture, prepares the surface for high-quality decorative cladding.