In the design and construction of private real estate, every detail counts. The homeowner should think carefully about everything - the foundation, walls, floor slabs and roof. Of no small importance for the durability of the structure is the quality of the exterior finish. Facade panels are an excellent solution for this stage of construction. This version of wall covering is practical, easy to install and excellent in appearance. Another reason in favor of such a choice is that cladding panels for finishing the facades of private houses can be installed with your own hands, saving a lot of money on the services of hired workers.

What are facade panels

When planning the decoration of the walls of a building, it is necessary to solve several problems at the same time: insulation, waterproofing and making it presentable. Neglecting even one of these criteria leads to practical and moral costs. The choice of facing methods that would satisfy all the requirements is very limited. The available technologies are either too expensive or not practical enough.

Traditional plaster cracks over time and is not strong enough. Pasting with bricks or ceramic tiles is associated with a large amount of wet work and high labor costs. At the same time, both options do not provide the proper level of thermal insulation. And this indicator is important for any climate.

The problem can be solved by using composite panels for the facade. The items are rectangular, square and hexagonal fragments with a decorative outer surface. The panels are fastened not to the walls, but to the frame located at a certain distance from them. The use of such a finish is aimed at cladding and masking the insulation installed in the frame.

Panels are made in single and multi-layer versions of ceramic, plastic and metal. The outer surface can imitate stone, wood, brick and other types of finishes. The kit comes with a mount, as well as detailed instructions for installing the finish. The cladding can be mounted on wooden, brick and panel buildings, there are no restrictions on the use.

Advantages and disadvantages

Facade panels for exterior decoration of the house have an almost unlimited scope. They are used for arranging walls and a cement basement of residential, utility and office buildings.

The material has the following advantages:

- Wide range of products. On sale are products that differ in shape, size, color and texture. The developer has access to panels for every taste and design.

- Easy to install. Even a novice craftsman can easily decorate his building with panels.

- Excellent insulating qualities. The composite facade reliably protects the building from dampness, heat and cold, ultraviolet radiation.

- Ecological cleanliness. The production uses raw materials that are absolutely safe for human health and the environment.

- Long service life - from 50 to 100 years.

- Affordable cost. The polymer coating is made from by-products of the chemical industry, which has a positive effect on the final price of the product.

This type of cladding has weaknesses:

- Limited resistance to mechanical stress. Plates are attached to the frame. All structural elements can be damaged by impacts.

- The complexity of the repair. If one panel breaks down, you have to dismantle the entire surface, since all its components are interconnected.

- Quite a large weight of the frame and sheathing. The walls made of foam concrete and sand-lime bricks are not suitable for this.

The material has much more advantages than disadvantages. Thanks to this, it continues to gain popularity among private and industrial developers.

Varieties of facade panels

When choosing cladding panels, one should take into account their weight, strength, base properties and operating conditions.

Products of this type are on sale:

- Metal with a polymer coating. The slats are available in aluminum, black and stainless steel. The coating protects the metal from corrosion, imitates various natural and synthetic materials.

- Fiber cement. Produced by mixing cement and polymer fibers. Fiber cement slabs for facades are lightweight and have excellent thermal insulation qualities. The disadvantage is that fiber cement is brittle and easy to break.

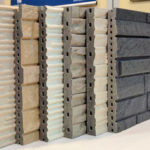

- Made of wood fibers. In the manufacture, chips impregnated with an antiseptic and lignin are used as a binder. The boards are lightweight and have low thermal conductivity.

- Made of stone. Selected granite, marble or dolomite rocks. Stone cladding is distinguished by the highest strength, durability, wear resistance and presentability. The disadvantage is a lot of weight, which implies the arrangement of a strong frame on a reliable base.

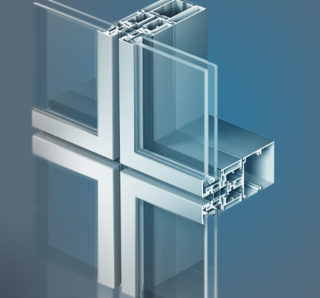

- Glass. This is the most expensive building design option. The decision to make a curtain facade out of glass is made to create an appropriate image for the property owner. To increase the safety of the finish, you can sheathe the house with monolithic polycarbonate, which is more durable than silicate glass.

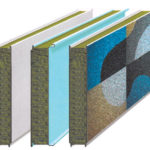

- Sandwich panels. Unique products consisting of a heat-insulating layer, an external decorative coating and a protective backing. They are characterized by sufficient strength and durability. Typically, foam is used as insulation.

- Thermal panels. If you choose this option for finishing your home, you can be sure that there will be a comfortable microclimate inside the premises at any time of the year and in any weather. The slabs are based on basalt wool, which is an additional fire protection.

- Vinyl. PVC siding is the most inexpensive and easy-to-use material used for finishing the facades of buildings for various purposes. The strips are quite durable and look quite decent. They are mounted on a metal frame in a horizontal orientation.

When choosing a material for cladding, you must initially decide on its practical and aesthetic purpose, value your own financial capabilities and construction skills.

Necessary tools for the job

For the installation of facade panels, it is enough to have a standard set of tools:

- puncher;

- hacksaw or jigsaw, grinder;

- screwdriver;

- level, square, tape measure, marker;

- putty knife;

- a hammer;

- scissors for metal;

- antiseptic, deep penetration primer;

- paint brush.

Depending on the selected material and the method of fixing the panels, the list can be shortened or expanded.

Do not forget about safety precautions. When finishing the facade, it is recommended to use protective goggles, gloves, skin and respiratory protection.

DIY installation features

Correct installation of panels outside the building should be carried out in stages:

- Carry out measurements, draw up a diagram, calculate the need for materials. It is necessary to provide a margin of 10-15% for errors and trimming.

- Prepare the base.Remove gutters, wires, plates, lamps and other items from the facade. If there are rotten boards, they need to be repaired or replaced.

- Galvanize a metal profile if it is made of black iron and does not have a protective coating.

- Mark the walls. Check the compliance of the parameters vertically, horizontally and diagonally.

- Cut out blanks for the frame and process the sections against corrosion and decay.

- Install the frame in accordance with the previously marked markings. Check the strength of the structure. The profiles must be fastened first vertically, and then the lintels.

- Insulate the frame. Here, for each material, its own technology operates.

- Install panels. After that, you need to check their alignment, seal up the joints and wait until the coating is ready for use.

The panels are serviced regularly based on the material composition and climatic conditions. In most cases, it is sufficient to use a hose.