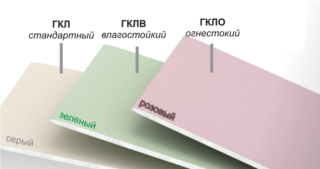

Plasterboard is a material that has been used in construction for a long time when arranging interior premises. It was invented in America, and for the first time the "building board" (10 layers of paper holding a strip of gypsum) was demonstrated and patented by the businessman Augustine Sackett in the 19th century, and the engineer Clarence Utsman improved and then received a patent for a modern version of drywall. It appeared in the USSR in the 50s of the last century and very quickly became a truly "folk" material. Since then, the domestic industry has mastered and is now massively producing several types of drywall: ordinary (GKL), moisture resistant (GKVL), fire resistant (GKLO), etc.

Advantages and disadvantages

Drywall sheet has a lot of advantages in comparison with other building materials:

- light weight;

- low moisture absorption (no more than 10%);

- vapor permeability;

- flexibility;

- versatility - that is, the ability to any type of finish (painting, gluing tiles, etc.);

- the ability to hide engineering communications behind plasterboard structures.

Drywall is absolutely non-toxic, has good soundproofing properties, as well as high resistance to water penetration and fire resistance.

The disadvantages of drywall include:

- relative fragility;

- the need for finishing;

- low water resistance;

- the need to assemble the mounting frame.

However, the main disadvantage of this material is considered to be the fact that when creating structures from it, the volume of rooms is somewhat reduced.

The choice of material and the necessary tool

Before starting work with drywall sheets, you need to decide what material to make the frame from for their installation.

For wooden lathing, a flat bar with a cross section of at least 40x40 mm and a length of about 2-4 m is used. In this case, the wood must be carefully treated with protective impregnations or coatings, otherwise the wood will mold and rot. The beams must be well dried, as the frame made of raw material will "lead" over time and cracks will appear on the finished surface.

The frame made of a special metal profile is not threatened by mold and decay. Warping is not typical for him. However, the quality of the protective zinc coating must be checked. The thickness of the profile walls must be at least 0.6 mm.

It is possible to sheathe a wooden house inside with drywall without a frame - by gluing or screwing its sheets with self-tapping screws to the walls and ceiling. However, the surfaces of the walls and ceiling must be perfectly flat, which is extremely rare. And this is possible only in those houses where there is practically no shrinkage.

The choice of drywall is carried out based on the type of room in which it will be mounted. For finishing the chimneys, you will need a fire-resistant material, and in bathrooms, toilets and kitchens, it is better to use a moisture-resistant material. In other rooms, as a rule, standard wall and ceiling plasterboard sheets are used.

In addition, during the work, you will need the following materials:

- starting and finishing putty;

- serpyanka mesh;

- double-sided masking tape;

- primer.

For the primary processing of drywall sheets after installation on a frame (metal profile), you will also have to purchase an antiseptic impregnation.

Tool

To quickly and efficiently assemble the frame and fix drywall on it, you will need in a wooden house:

- drill;

- building level;

- roulette;

- screwdriver;

- sets of drills and bits;

- stationery knife with a stock of blades;

- self-tapping screws of various lengths;

- plastering accessories (mixing container, drill attachment, set of spatulas, etc.)

If a decision is made to equip a metal frame, you will also need a grinder and a hacksaw for metal. To assemble a wooden lathing, you need to additionally prepare a hacksaw for wood.

Preparatory work

The preparatory work that must be carried out before facing the walls of a wooden house with sheets of drywall includes:

- inspection of wooden walls and elimination of detected defects;

- treatment of walls with antiseptic and flame retardant impregnations;

- installation of a metal frame or wooden lathing;

- laying of insulation and electrical wiring (if necessary).

Installation of drywall inside a newly built wooden house cannot be carried out. It is necessary to wait at least one year - during this time, the main shrinkage of the house and the shrinkage of the wood will end. An exception can be made only in houses made of laminated veneer lumber, which are characterized by minimal shrinkage.

Preparing the surface for arranging the lathing

Before proceeding with the assembly of the frame (lathing) for drywall, all walls and the ceiling must be prepared. For this you need:

- remove the old coating (if necessary);

- wipe the surfaces with a damp cloth to remove dust and dirt;

- prime the surfaces thoroughly and wait until they dry completely;

- cover existing large cracks, potholes, etc with mortar;

- plaster the surface;

- level the surfaces using a level and cement mortar.

In rooms with high humidity, it is required to additionally treat the surfaces with plaster putty - this will prevent the spread of the fungus.

Types of frames for a wooden house

For wall decoration with plasterboard, several types of frame structures are used. For example, in old wooden houses, a wooden crate or a metal profile frame is most often used. Both options belong to the category of rigid frames and provide the most snug fit and reliable fastening of drywall. However, rigid frames are not suitable for newly built timber houses that are prone to shrinkage. In this case, it is better to use a floating wireframe that does not have rigid edges.

Metal profile frame

When installing drywall sheets, a metal profile frame is most often used. This is due to the fact that its design is capable of withstanding high loads. At the same time, the metal profile is somewhat more expensive than wood, and it is more difficult to assemble it. If the room is planned to be lined with drywall not only of the walls, but also of the ceiling, at first the metal frame is mounted on it. In this case, the electrical wiring is first spread across the ceiling (if necessary).

The metal frame can be multi-level, curved (facing fireplaces, arches, etc.) or round.

Wooden lathing

The lathing on the walls and ceiling is assembled from a bar or slats. First, elements are attached to the ceiling and floor using self-tapping screws, which will serve as guides. The same elements are mounted on the walls on the right and left. After that, the main racks are installed.

The rails are connected to the guide rails with straight hangers. The optimal pitch between the hangers is 40 cm, and between the guides 30 cm.To make the lathing strong, transverse slats of the same material are installed on it. Self-tapping screws and mounting angles act as fasteners.

In the same way, the frame is assembled on the ceiling, and the step between the beams depends on the area of the ceiling and should be approximately in the range of 60-80 cm.

Floating frame

The floating frame for drywall is based on a wooden box made of dense types of wood, pre-treated with an antiseptic. This box along the perimeter of the wall is not fixed, but mounted on special sliding suspensions. At the same time, drywall is attached to the frame assembled in a box.

There must be a gap between the wall (ceiling) and the box, which allows the drywall to remain stationary when the shape of the wall or ceiling changes. In this case, the existing gaps are hidden under the baseboards.