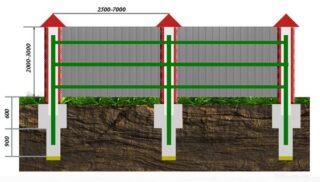

The fence consists of a foundation, uprights and filling. The main bearing load is borne by the supports. The size and depth of digging is affected by the weight of the entire structure, the material of the column, the nature of the soil.

Pillar pitch and size

The main factor that determines the distance between the posts and their dimensions is the material from which the posts and the filling are made. It is important to find the optimal balance between the installation frequency and the strength of the fence.

Main settings:

- Height - the maximum possible reaches 2.5 m.However, more often it is much less, since this value is regulated not only by SNiP, but also by the local administration. Most often, a blind fence can reach a height of no more than 70 cm, and a lattice or mesh fence - 120-200 cm.

- Filling material - a canvas from a chain-link mesh freely passes not only light, but also air. Such a fence is exposed to much less wind loads than a blank canvas made of euro shtaketnik. For the mesh structure, powerful pillars are not needed, so profile pipes can be taken for the racks. But the deaf wooden compartment has a high windage and it will require more massive pillars.

- Installation frequency - the heavier and higher the compartments, the greater the load they put on the foundation. For this reason, it is better to make the posts more massive than to put up the posts more often. This option will only increase costs and worsen the appearance of the fence.

When calculating the installation step and the size of the post, it is necessary to take into account the support posts installed at the corners of the site and those that frame the openings of the gates and wickets. At the same time, it is important to maintain a constant distance between the intermediate posts in order to achieve an even distribution of the load on the foundation.

Material selection

The choice of rack depends on the total weight of the structure and the filling material. For the mesh-netting, powerful pillars made of brick or concrete are not needed. For a forged lattice, they will be needed, especially if the fence is high.

Other factors are also taken into account: ease of processing, the nature of the foundation required for a particular fence, the compatibility of support and filling materials. The most popular are the following materials:

- Wood is an affordable material and very easy to process. The wood is easy to cut and sawn, withstands high load-bearing loads and looks great. However, the tree is sensitive to moisture and the sun, so the pillars need to be periodically treated with antiseptics, primers, stains or paints.

- The metal profile is a universal option. For fencing, rectangular or square shaped pipes are taken, since it is easier to fix corrugated board, lattice or mesh to them. A black steel profile is also afraid of water, it also needs to be primed and painted. But it is more durable, stronger and not afraid of temperature changes.

- Asbestos-cement - durable lightweight pipes that do not corrode. They do not rot, they are very durable. Burying asbestos-cement fence posts is no more difficult than wooden ones. Minus - complex fasteners. To install the lag, you will need special pins.

- Concrete - made by hand or purchased ready-made. Concrete supports can withstand the heaviest loads. Very durable, maintenance-free.However, burying the posts is more difficult due to their heavy weight.

- Brick is the most aesthetic option. The pillars are made of the same brick or stone as the residential building and immediately connect the facade and the fence into a single composition. Minus - they are more expensive and installation takes more time.

When choosing a material, it is necessary to evaluate the method of instillation. Metal or wood blocks can simply be driven into the soil, which is cheaper and easier. Asbestos-cement or concrete are concreted in the foundation, which takes time and effort.

How to choose depth

To what depth to bury the pillars depends on the material of the support, the nature of the soil and the method of fixing the pillar in the soil.

- If the filling is a light material - a net, a wooden picket fence - the standard is the depth of 0.7–0.8 meters. This design does not apply to capital, but if the fence is damaged by the wind, the position of the post can be corrected with an ordinary hammer.

- If the material is heavier - a profiled sheet, a wooden sheet, a euro-shtaketnik, - the post is buried 20 cm below the freezing depth of the soil. This indicator is found in the reference book; it is different in each region.

The nature of the relief is also taken into account. If the site is located in a lowland, the level of groundwater here is noticeably higher. In this case, the pillars need to be deepened more.

Factors Affecting Rack Installation Depth

The nature of the soil affects the depth of immersion in the ground no less than the height and weight of the fence. Depending on the type of soil, the method of burial is chosen.

Installation in dense ground

The best soil for construction is dense sandy or clayey soil. In this case, any fence can be installed around the site. With a standard fence height of 2 m and a section width of up to 2.5 m, the immersion depth does not exceed 80 cm. If the fence is heavy, they are buried to a depth of 100 cm, but this is rare.

Installation methods:

- driving into the ground - this is how metal racks, metal profiles, timber are immersed;

- backfilling - recommended for continuous filling;

- driving with partial concreting.

In areas with black soil or other loose soil, the pillars are buried to a layer of dry clay.

Supports in heaving soil

Such soil freezes easily and pushes out the pillars immersed in it. Here it is important to dig a hole for support below the freezing level of the soil by 20-50 cm.

The pillars are installed using the partial filling method. The lower part of the support is concreted so that the concrete level does not go beyond the border of freezing, and the rest of the trench is covered with sand and gravel, watered and tamped.

Heavier fences are installed on screw piles.

Installation on collapsible soils

This category includes loam, loess and other clayey loose soils. Such soil, if poured with water, gives strong shrinkage. The same thing happens under load, so a heavy fence in such soil literally sinks into the ground if the load cannot be properly distributed. The immersion depth is calculated simply - 1/3 of the height of the post above the ground.

Installation is difficult. In simple cases, hammering or backing is used. But if the fence is made at least from a solid sheet of wood or slate, they resort to a different method. Dig a wider hole for the pillar to the bottom of the iron support and weld the sheets. Then the trench is poured with concrete or cement.

When you need a foundation

Any fence requires a foundation. However, for light models, a point option is used: partial concreting of the support after immersing it in the soil. The latter option is formally considered a fence without a foundation. This is possible when installing a fence on dense clay soils.

The heavier the fence, the more powerful the base is needed. If a stone or brick fence is being erected, high forged, a foundation tape is needed. The options are different.A shallow foundation is equipped together with columnar bases, and screw piles are combined with a grillage.

In order for the fence of the site to serve for a long time, it is necessary to correctly calculate the load on the support pillars. Only after calculations can you choose the material of the posts, the depth of immersion in the ground and the method of installation.