The operating conditions for building materials for a bath are very different from other premises. In the steam room, the temperature can reach 80–100 degrees with a humidity of 60 to 98%. Moreover, the load is one-time and after bathing the room is cooled. The arrangement of the ceiling in the bath must meet such extreme conditions.

The construction of the ceiling in the bath

How to make a ceiling in a bath depends on the height of the rooms in the bath complex, on the type of roof - rafter or rafterless, on the size of the steam room. The ceiling requirements are very high:

- You can use the steam room only if the microclimate is maintained in it without special costs. For this, the structure must be sufficiently insulated to maintain the temperature in the room.

- In the steam room, the humidity can reach 90%. The ceiling, as well as the ventilation system of the bath, should prevent steam from entering the attic.

- Finishing the ceiling in the bath under the influence of temperature and moisture should not emit harmful substances, therefore, any options for synthetic cladding are excluded.

- Materials are chosen as fireproof as possible. In fact, we are talking only about flame retardant impregnations.

- The ceiling trim, like the base material, must be sufficiently resistant to moisture and steam to last at least 10 years.

- The design of the structure is also worth paying attention to.

The ceiling device is quite complex and includes several layers: decoration, vapor barrier, insulation, waterproofing, attic floor.

Material selection

For the sauna room, especially for the steam room, you need to select a special tree. No less attention is paid to the choice of other materials:

- Wood for the frame - most often conifers are taken. They contain a large amount of resins, and this makes the material resistant to water and steam. In addition, pine, spruce is much cheaper than hardwood, and rather massive beams are needed for the ceiling frame.

- What to make the ceiling in the steam room or dressing room depends on the same parameters. The room takes on the "brunt" of hot air, moisture and condensation. Conifers are not suitable here: they release resin when heated, which is unacceptable indoors. They take hardwoods that are resistant to steam and heat: linden, alder, aspen. Linden is preferable: the wood is very beautiful and exudes a pleasant aroma.

- Vapor barrier - a layer in front of the insulation. The insulation must be protected from water. Vapor barrier - membrane, glassine, foamed polyethylene - prevents condensate and steam from entering the insulation layer.

- The choice of thermal insulation layer determines the design of the ceiling. In the bath, it is almost impossible to insulate it from below, so that the layer is placed on the side of the attic between the floor logs. Mineral and basalt wool is more often used: it is fireproof, perfectly retains heat, and muffles sounds. It is afraid of water, but a vapor barrier layer protects it from the action of steam. You can take cheaper materials, for example, expanded clay. The pebbles are poured in a fairly thick layer, and the floor is laid on top in the attic. Straw, dry leaves and sawdust are allowed but not desirable: materials are highly combustible.

- Waterproofing - non-woven or film coatings prevent water from entering the insulation layer.

Fasteners are selected from galvanized steel.Finishing nails are better made of copper or brass.

Varieties of ceilings in the bath

The ceiling is finished in 3 main ways: hemming, flooring, panel. They differ in the technologies and materials used, therefore, the option should be determined at the design stage, or at least the construction of walls.

Grazing

The easiest and cheapest styling option. The main difference from other models is the absence of ceiling beams. Floor boards are fixed directly into the wall logs. To do this, grooves are made in them - they cut off a quarter of the log. In the attic, it is difficult to move on the floor floor, in fact, you have to walk on the insulation. This option is suitable only for small baths, if the attic serves as a technical room. Sometimes the rough floor is trimmed with clapboard.

The advantages of the method are its low cost and ease of construction and repair. The disadvantage is the limited use and difficulty with insulation.

Hemming

In large bath complexes, high strength is required from the overlap. A false ceiling is quite suitable even if the attic is used as a living space.

The basis of the overlap is the ceiling beams installed on the last crown of the log house. They serve as a support for the attic floor and pull the walls together, strengthening the overall structure. The ceiling is, as it were, suspended from the bottom to the beam system, for which it received its name.

This option allows you to make insulation inside the floor. For this, mineral or basalt slabs are fixed between the beams.

The advantages of the frame structure include very high strength and reliability of the structure, durability, high-quality insulation. The disadvantage is the much higher cost. Additional costs are required for the installation of beams and for insulation.

Panel

Convenient, albeit peculiar solution. It is based on pre-fabricated panels. This is a kind of pallet or box with low sides on both sides, which are assembled from just about anything: any tree is suitable. Insulation is placed inside the box - of any kind, trimming is also allowed, although it is preferable to take insulating mats. A layer of vapor barrier is placed under the insulation, and a waterproofing material is placed on top.

At the level of the overlap, a powerful frame is built from a bar, panels are installed on it, tightly joining each other. The panels are fastened with boards, the gaps between them are filled with jute, and ordinary boards are laid on top, forming the floor in the attic.

The advantage of the design is the relative cheapness, since any wood and any quality can be taken for the panels. It is easy to repair or replace. The disadvantages include a rather large mass and the need to seal joints and seams well.

Required tools and materials

All materials for the bath ceiling are divided into rough and white. The former can be poorly processed, of low grade, consist of cuttings, but have sufficient strength or density. White must also satisfy aesthetic requirements.

Most often, a hemmed ceiling is built in the bath. It is expensive to perform, but the long service life and reliability fully compensate for this.

The construction will require:

- timber for beams made of coniferous species with a section of 50 * 50 mm, not less;

- boards for external sheathing - can be unedged, low grade;

- boards for interior decoration - edged, lining;

- vapor barrier membrane - it is better not to use plastic wrap in the steam room, but it is quite suitable for a dressing room or shower;

- insulation - mineral or basalt wool; polyurethane foam is undesirable, it is flammable;

- waterproofing membranes;

- marking tool - square, tape measure, level;

- saw or hacksaw for wood;

- hammer and screwdriver or air gun.

You will need stationery: a pencil, scissors, a paper knife - it is easier for them to cut the mineral wool.

DIY installation guide

The construction is quite simple, but requires the ability to work with carpentry tools.

- For the beams in the last crown, grooves are cut out with an ax for connection into a "fat tail".

- Bars are laid in increments of 1-1.5 m. If necessary, make a drawing. It is better to take the same wood from which the crown is made. It is preferable to use a bar, since it is much easier to mount it due to its rectangular cross-section. If logs are laid, they will have to be cut on one side in order to be able to hem the trim.

- Mats are made - ceiling beams. The timber is cut to size, the edges of the logs are cut to a depth of 1/8 of the thickness.

- Ceiling beams are installed, achieving a tight fit. The seams are sealed with tow or inter-crown insulation.

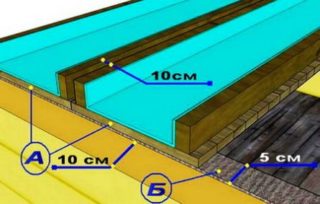

- A vapor barrier film is fixed to the beams from below. Lay it with an overlap on the walls up to 10 cm. Along the perimeter, the material is fixed with mounting bars: they ensure a snug fit of the film.

- The overlap is sheathed with clapboard or edged boards made of linden, alder, aspen. The boards are laid perpendicular to the direction of the ceiling logs.

- Insulation is done from the attic. There is enough space between the lags to place both a layer of expanded clay and a mineral wool mat. The layer height is only 50 mm less than the height of the beams. The air gap ensures air circulation.

- Waterproofing is laid on top of the logs. It is fixed with construction brackets or simply leveled and held in one position during the installation of the floor.

- The attic floor is rough, so low quality planks are used. Their only task is to protect the insulation layer.

The space around the chimney is arranged according to a different scheme. The boards and finishes are flammable and must be prevented from coming into contact with the hot pipe. To do this, a kind of wooden box is built around the chimney, the walls of which recede from the walls of the chimney by at least 25 cm.Then the walls and edges of the box are sealed with metal plates, and the box is filled with non-combustible insulation - the same expanded clay or basalt wool.

The area on the ceiling and floor around the chimney is also covered with a metal sheet.

Maintenance of the ceiling in the bath is minimal. In the steam room, paint and varnish materials cannot be used, so all procedures are reduced to periodic processing of the material with antiseptics. Since the wood darkens from the heat, bleaches are used to restore a light shade to the ceiling.

The overlap in the bath is a simple design. However, you can only use materials that are resistant to water, steam and temperature, and do not pose a health hazard.