Brick is a type of building stone with precise geometric shapes and standardized dimensions. Such an element is very convenient: the seams between the stones are minimal, installation is simple. There are many types of bricks and any of them can be used to construct a building.

Varieties of bricks for building a house

The types of bricks for building a house are very diverse. Each of the options has its own advantages and disadvantages. However, some materials are intended for arranging individual elements of a building - a stove, for example, or a facade, others are used for the construction of load-bearing or interior walls.

Building

Red ceramic bricks are the most common option. It is used for the construction of foundations, walls, partitions, architectural elements of any type. Low-melting clays are used for manufacturing. The firing temperature is 900-1100 C, so the stone is not afraid of any temperature changes.

They produce a hollow and corpulent version. The first one has higher thermal insulation properties and less weight. For the foundation, take a corpulent one. There is also a facing material: it has more precise dimensions and a smooth front surface.

Unburned clay stone loses half of its qualities. This material has a characteristic pink tint.

Facing

Such a brick for the house is used to decorate an already erected facade. Characteristics:

- higher density, since the cladding is designed to protect the walls from mechanical damage;

- low porosity - the facing stone is non-hygroscopic, does not absorb water and tolerates cold;

- smooth surface and dimensional accuracy, which ensures perfect brickwork;

- unusual shape - besides rectangular, clinker can be triangular, rounded, curly, twisted.

The color range of the facing stone is much larger than that of other types.

Silicate

The material is popular due to its low price. It is made from a mixture of quartz sand and lime. Due to chemical reactions, the brick is gaining good strength and density and can withstand high load-bearing loads. Silicate stone is more often used in multi-storey construction.

For a private house, the option is not the best. Sand-lime brick is afraid of moisture, is unstable to high temperatures and does not retain heat.

Hyperpressed

Outwardly it resembles a natural stone. The composition is varied: shell rock, dolomite, marble, limestone. The binder is cement. Hyper-pressed brick is very durable, non-hygroscopic and can withstand up to 150 full freeze cycles. However, the stone weighs a lot and does not retain heat, since it belongs to low porosity. It is used for interior and exterior decoration.

Clinker

A variant of a facing stone obtained from refractory clay. The clinker is distinguished by the highest density, hardness and extremely low porosity. It withstands the most severe cold and does not lose its appearance.

The clinker is very expensive and does not retain heat, so it is not used for the construction of load-bearing walls.

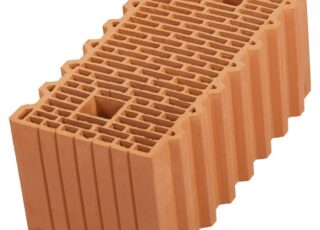

Porized

Option for building clay. The very material of the stone obtained from clays has the strength and density of ceramics. However, the brick includes many small cavities, cells filled with air.As such, there are no pores in the material, that is, moisture does not penetrate inside. At the same time, cavities reduce the weight of the stone and provide excellent heat and sound insulation properties.

Stove

It is made from special fireclay clay and has a very high fire and heat resistance. The stone is used for laying stoves and fireplaces or for cladding any other surfaces in contact with a flame.

The difference in material by external signs

For construction, choose a brick that is suitable in size, properties and purpose.

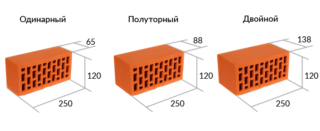

To size

- single - 250 * 120 * 65 mm;

- double - 250 * 120 * 138 mm;

- one and a half - 250 * 120 * 88 mm;

- modular - 280 * 130 * 88 mm.

Euro is also allocated - 250 * 85 * 65 mm.

The dimensions of the special variants differ. Fireclay Ш-5 has dimensions of 230 * 114 * 65 mm, Ш-6 - 230 * 115 * 40 mm. Clinker or any facing has a minimum thickness: 290 * 140 * 85 mm, 250 * 85 * 65 mm. Cinder blocks, on the other hand, are much larger.

By the nature of the filling

By type and amount of filling, they are distinguished:

- corpulent - does not contain voids, usually considered as a structural material;

- hollow - includes cavities, cells, voids of complex shapes. Such a stone retains heat better.

Porized also refers to hollow, although it has an unusual appearance.

In appearance

Standard bricks are rectangular in shape, making them easier to lay. The facing side can be embossed or textured to create a more effective look. Also, the finishing stone can be rounded, trapezoidal, polygonal and figured.

The color of the building stone most often remains natural: red in clay, gray-white in silicate. In the manufacture of the facing material, various coloring pigments are added to the initial mass, therefore the clinker or hyper-pressed stone can be yellow, purple, blue.

Highlights when choosing

When choosing a brick for a home, you need to take into account the technical characteristics:

- Frost resistance - this indicator differs for different materials. The clinker can withstand from 100 to 150 full freeze / thaw cycles, and the silicate one - no more than 25. If the house is being built in the southern regions, high frost resistance is not needed.

- Durability - the brand describes this characteristic. The most popular brands include M100, 125, 150, 170. For a one-story building, the first option is sufficient. For a three-story building - at least M150.

Determination of brick quality:

- The use of clays in the manufacture provides the material with "sonority", but only when properly fired. If, when struck with a hammer, the stone makes a ringing sound, its quality is beyond doubt. If deaf, this is a sign of insufficient firing temperature or irregularities in the composition.

- The color remains characteristic of the raw material. The red clay should not be pinkish or brown, and the interior should not be black.

- Pay attention to the surface - cracks and depressions are excluded.

- Not only the brand is indicated on the stone, but also the batch number. If not, it is better to find another seller.

For load-bearing walls, they take clay, silicate, porous bricks, for finishing - clinker, hyper-pressed, finishing. For the construction of special elements - a fireplace, a stove - a refractory version will be required.